2024-03-01

Ningbo Haishu Nide International Co., Ltd is specialized in bearings export production selling and after-service. In practice for many years, we established strict quality assurance system. Our products range covers insulation paper,magnet,carbon brush,commutator,shaft,thermal protector,fan,deep groove ball bearings, spherical roller bearings,ball bearing,motor cover and lamination,etc.We can do OEM products, and do following drawings.

Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing. Make motor, turn to Nide, everything will be easy !

ball bearing---FAQs Guide

1.How do ball bearings affect the operational efficiency of machines?

We focus on innovation and continuous improvement to maintain a competitive advantage.

Ball bearings play a crucial role in the operational efficiency of machines. They are small, round, and smooth balls that are placed between two surfaces to reduce friction and allow for smooth movement. Here are some ways in which ball bearings affect the operational efficiency of machines:

1. Reduced Friction: Ball bearings are designed to reduce friction between two moving parts. This means that less energy is required to move the parts, resulting in improved efficiency. The smooth surface of the balls also helps to reduce wear and tear on the machine, increasing its lifespan.

2. Increased Speed: The reduced friction provided by ball bearings allows machines to operate at higher speeds without overheating or wearing out. This is especially important in high-speed machines such as turbines and engines, where any increase in speed can significantly impact efficiency.

3. Improved Precision: Ball bearings provide a smooth and consistent movement, which is essential for precision machines. They help to maintain the accuracy of the machine's movements, resulting in better quality products and reduced waste.

4. Lower Maintenance: The use of ball bearings reduces the need for frequent maintenance and repairs. As they reduce friction and wear on the machine, they help to extend its lifespan and reduce downtime, resulting in improved operational efficiency.

5. Versatility: Ball bearings are available in various sizes and materials, making them suitable for a wide range of applications. This versatility allows for the use of ball bearings in different types of machines, improving their efficiency and performance.

In conclusion, ball bearings are essential components in machines that significantly impact their operational efficiency. They reduce friction, increase speed, improve precision, and require less maintenance, making them crucial for the smooth and efficient functioning of machines.

2.What are the characteristics of mating bearings?

1. Symmetrical design: Mating bearings are designed to be symmetrical in shape and size, allowing them to fit together perfectly.

2. High precision: These bearings are manufactured with high precision to ensure a tight fit and smooth operation.

3. Interchangeability: Mating bearings are designed to be interchangeable, meaning they can be used in different combinations without affecting performance.

4. Self-aligning: These bearings have the ability to self-align, which allows them to compensate for any misalignment between the mating parts.

5. Low friction: Mating bearings are designed to have low friction, which reduces wear and tear and increases the lifespan of the bearings.

6. High load capacity: These bearings are capable of handling high loads, making them suitable for heavy-duty applications.

7. Lubrication: Mating bearings are designed to be lubricated, which helps reduce friction and wear, and also helps dissipate heat.

8. Corrosion resistance: These bearings are often made from materials that are resistant to corrosion, making them suitable for use in harsh environments.

9. Noise reduction: Mating bearings are designed to reduce noise and vibration, providing a smoother and quieter operation.

10. Easy installation: These bearings are designed for easy installation, with features such as snap rings or flanges that help secure them in place.

3.What scenarios are tapered roller bearings suitable for?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

1. Automotive industry: Tapered roller bearings are commonly used in the automotive industry for various applications such as wheel bearings, differential gears, and transmissions.

2. Industrial machinery: Tapered roller bearings are suitable for heavy-duty industrial machinery such as construction equipment, mining equipment, and agricultural machinery.

3. Railway industry: Tapered roller bearings are used in the railway industry for applications such as locomotive axles, wheelsets, and gearboxes.

4. Aerospace industry: Tapered roller bearings are used in aircraft engines, landing gear, and other critical components in the aerospace industry.

5. Heavy-duty equipment: Tapered roller bearings are suitable for heavy-duty equipment such as cranes, forklifts, and material handling equipment.

6. Power transmission: Tapered roller bearings are used in power transmission equipment such as gearboxes, pumps, and generators.

7. Paper and pulp industry: Tapered roller bearings are used in paper and pulp processing equipment for applications such as rollers, gears, and shafts.

8. Mining and construction: Tapered roller bearings are suitable for heavy-duty applications in the mining and construction industries, such as crushers, conveyors, and excavators.

9. Agriculture: Tapered roller bearings are used in agricultural equipment such as tractors, combines, and harvesters.

10. Marine industry: Tapered roller bearings are used in marine equipment such as propeller shafts, rudders, and winches.

4.What are the sealing methods for ball bearings?

As one of the ball bearing market leaders, we are known for innovation and reliability.

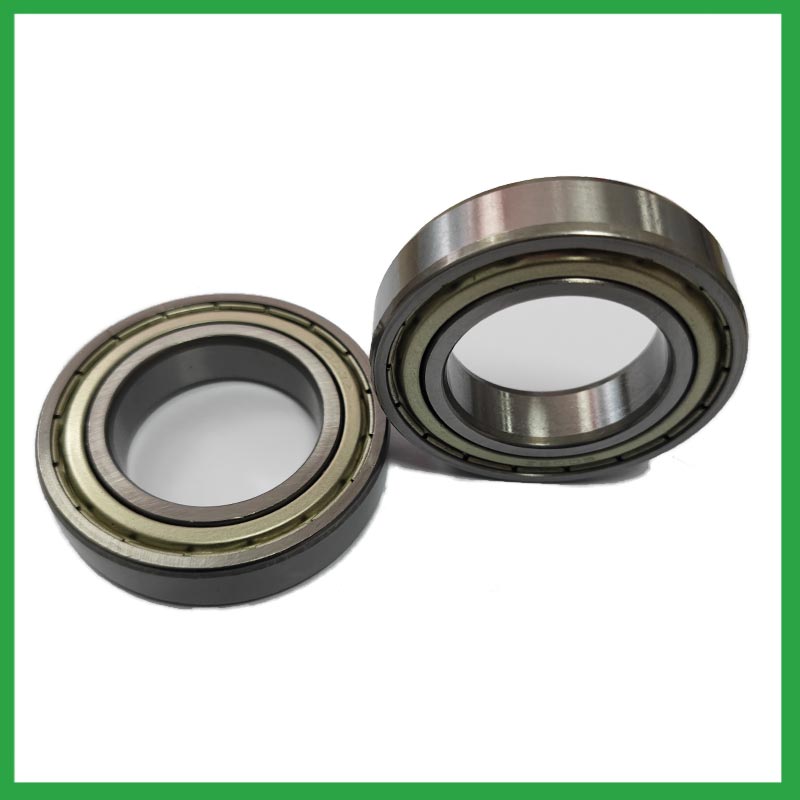

1. Shielded Bearings: These bearings have metal or rubber shields on either side of the bearing to protect it from dirt and debris. The shields are non-contact, meaning they do not touch the inner race of the bearing, allowing for smooth rotation.

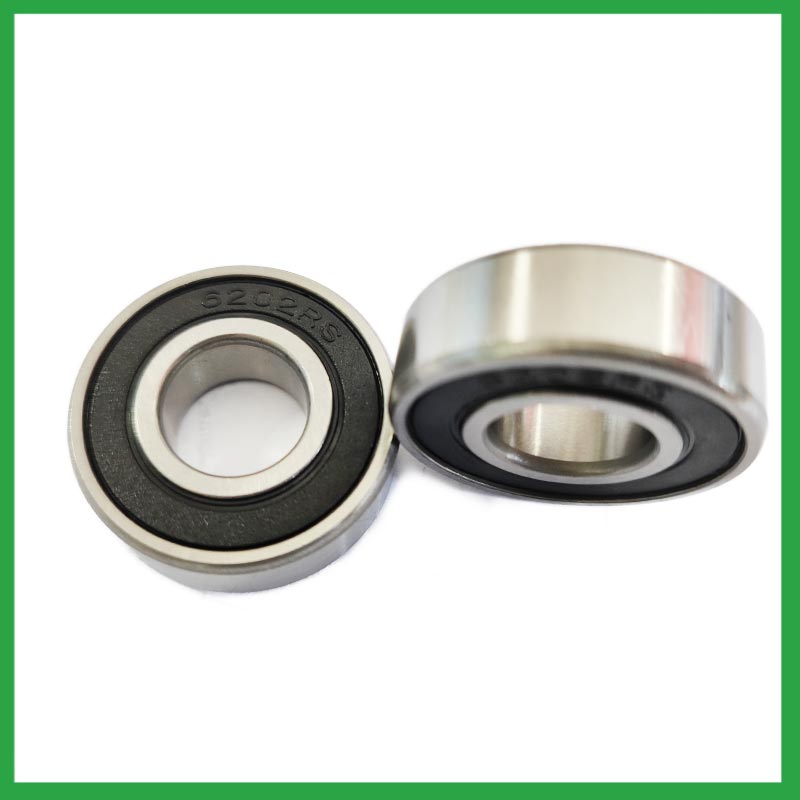

2. Sealed Bearings: Sealed bearings have rubber or metal seals on both sides of the bearing, creating a barrier to prevent dirt and debris from entering the bearing. These seals are in contact with the inner race of the bearing, providing better protection but also creating more friction.

3. Open Bearings: Open bearings do not have any shields or seals, leaving the bearing exposed. These bearings are used in applications where contamination is not a concern, such as high-speed or precision applications.

4. Contact Seals: These seals are in contact with the inner race of the bearing and provide a higher level of protection against contamination compared to non-contact seals. However, they also create more friction and can affect the speed and performance of the bearing.

5. Non-Contact Seals: These seals do not touch the inner race of the bearing, allowing for smoother rotation and less friction. They provide less protection against contamination compared to contact seals.

6. Labyrinth Seals: These seals use a series of grooves and ridges to create a maze-like path for contaminants to travel through before reaching the bearing. This method provides good protection against contamination while also allowing for smooth rotation.

7. Felt Seals: Felt seals are made of compressed wool or synthetic fibers and are used in applications where high temperatures or chemicals are present. They provide good protection against contamination and can withstand harsh environments.

8. V-ring Seals: These seals are made of rubber or plastic and are used in applications where there is a lot of axial movement. They provide good protection against contamination and can accommodate misalignment.

9. Magnetic Seals: These seals use a magnetic field to attract and trap contaminants, preventing them from entering the bearing. They are commonly used in high-speed and high-temperature applications.

10. Combination Seals: Some bearings may use a combination of different sealing methods to provide the best protection against contamination. For example, a bearing may have a shield on one side and a contact seal on the other side.

5.What are the characteristics of high-temperature ball bearings?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

1. Heat resistance: High-temperature ball bearings are designed to withstand extreme temperatures without losing their structural integrity or performance.

2. Material selection: These bearings are made from materials that can withstand high temperatures, such as stainless steel, ceramic, or high-temperature alloys.

3. Lubrication: High-temperature ball bearings require special lubricants that can withstand high temperatures without breaking down or evaporating.

4. Thermal expansion: These bearings are designed to accommodate thermal expansion and contraction, which can occur at high temperatures.

5. Clearance: High-temperature ball bearings have a larger internal clearance to allow for thermal expansion and prevent binding.

6. Sealing: These bearings are often equipped with special seals or shields to protect them from contaminants and prevent lubricant leakage.

7. Cage material: The cage of high-temperature ball bearings is typically made from heat-resistant materials such as stainless steel or high-temperature polymers.

8. Load capacity: These bearings are designed to handle high loads at high temperatures without compromising their performance.

9. Precision: High-temperature ball bearings are manufactured to high precision standards to ensure smooth operation at high temperatures.

10. Application-specific design: These bearings are designed for specific high-temperature applications, such as industrial ovens, kilns, and furnaces.

6.What is a mating bearing?

A mating bearing is a type of bearing that is designed to fit and work together with another bearing or component in a machine or mechanical system. It is typically used to support and guide rotating or moving parts, and is designed to withstand the forces and loads placed on it by the other bearing or component. Mating bearings are often used in pairs or sets to ensure proper alignment and distribution of forces within the system. They can come in various shapes and sizes, such as ball bearings, roller bearings, or plain bearings, and are commonly made of materials such as steel, bronze, or plastic.

7.What is a self-lubricating ball bearing?

We are centered on customers and always pay attention to customers' needs for ball bearing products. A self-lubricating ball bearing is a type of bearing that is designed to operate without the need for external lubrication. It contains a lubricant embedded within the bearing material, such as graphite or PTFE, which is released during operation to reduce friction and wear. This eliminates the need for regular maintenance and lubrication, making it ideal for applications where frequent lubrication is not possible or practical. Self-lubricating ball bearings are commonly used in high-temperature, high-speed, and harsh environments.

8.As a ball bearing manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.