PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide can provide turn-key service and technical consultance for motor production technology, it covers varies type motors.

Automatic Washing Machine BLDC Motor Production Assembly Line

The automatic motor assembly line is suitable for washing machine BLDC motor manufacturing. It includes automatic rotor production assembly line, automatic in-slot stator production assembly line, and automatic BLDC motor assembly line. The entire motor manufacturing assembly process is highly automated, improving efficiency and reducing labor costs.

1. Automatic BLDC rotor assembly line

Auto shaft inserting machine. This machine can automatic press-fitting the rotor core and shaft of the motor. The performance is stable and accurate, the pressing depth is uniform, and the precision is high.

Auto ball bearing inserting machine. The machine can automatically pressing the Bearings on both ends of the rotor.

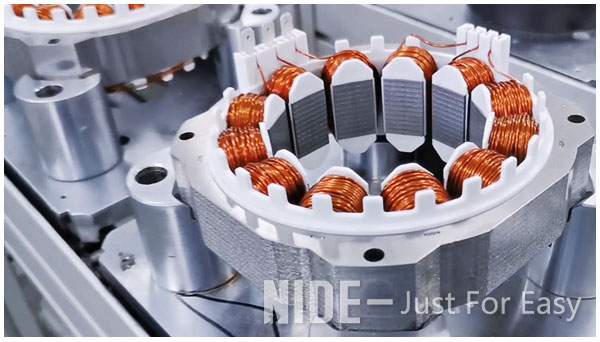

2. Automatic BLDC stator assembly line

Auto Insulation paper inserting machine. The machine can automatically complete paper cutting, folding and inserting.

Auto End insulator pressing machine. This machine automatically presses the insulation board end plate on both ends of the rotor.

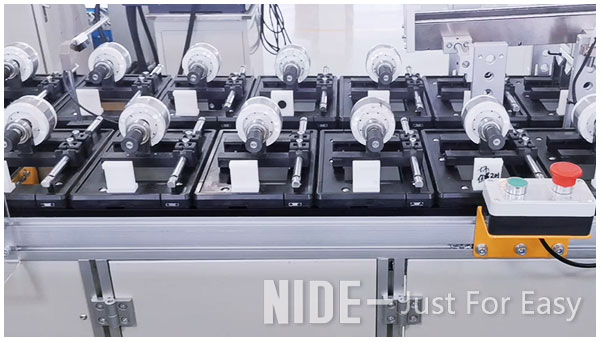

Auto Needle winding machine. The motor winding machine is suitable for the winding of the stator of the servo motor, the BLDC stator winder adopts the needle inner winding design, single-station operation, and can simultaneously wind three slots in the winding, and the whole coil winding process is automated and efficient, safe, multi-strand winding at the same time, the coil winding speed can reach up to 800 rpm, and different types of brushless stators can be wound according to customer requirements. This BLDC stator needle winder has self-diagnosis function.

Auto stator wire end termination machine. The stator termination machine automatically organizes the wire end. The wire end length can be adjusted.

Auto Terminal Inserting and Stator Testing Machine. The machine can automatically feeding, positioning, pick-up, pressing, test the stator performance.

3. Automatic BLDC motor assembly line

This automatic motor assembly line is suitable for assemble varies type BLDC motor, such as BLDC washing machine motor stator, compressor motor, vacuum cleaner motor, power tool motor, etc.We could accomplish tailored and innovative solutions to meet all quality and production requirements.

The BLDC motor motor production assembly line video

Nide provides turn-key service and technical consultance for motor production technology, it covers varies type motors. We could accomplish tailored and innovative solutions to meet all quality and production requirements, aim at making motor production easier.

Our fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com