PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

ND-SW01M

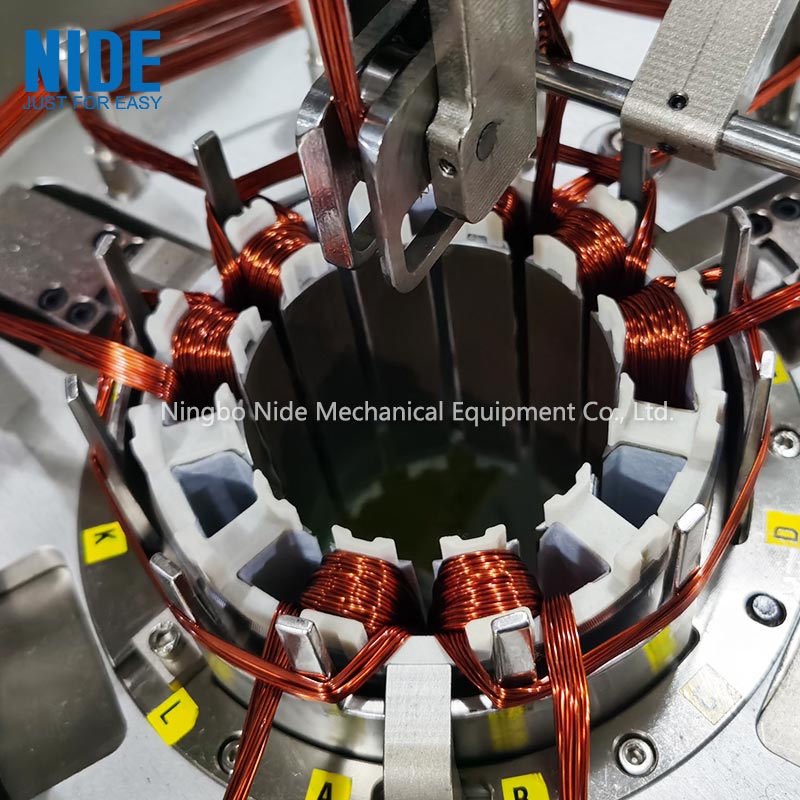

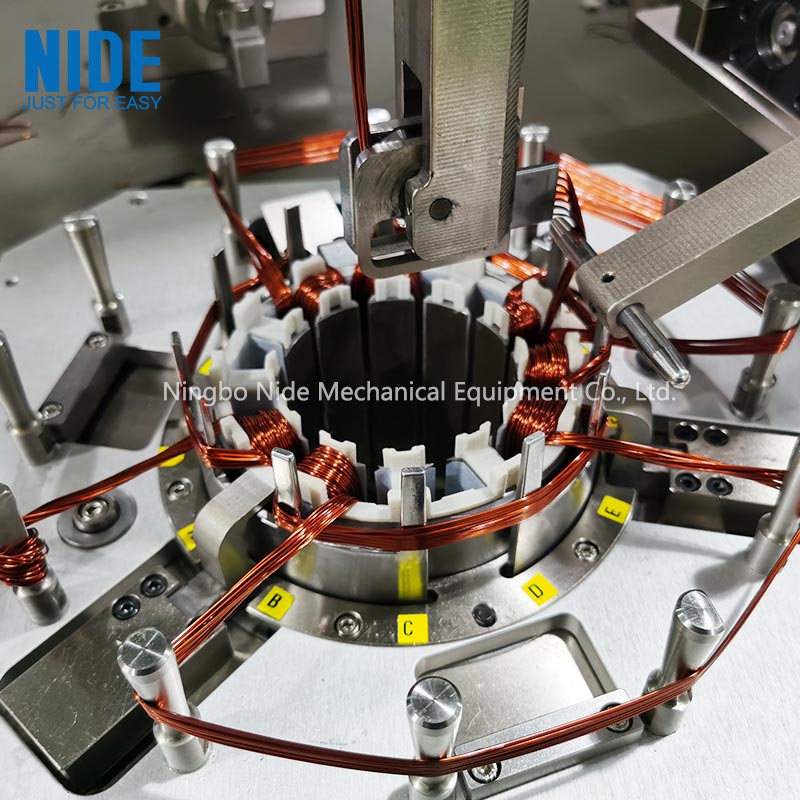

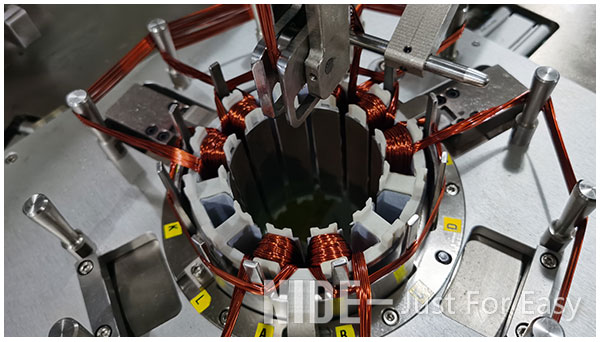

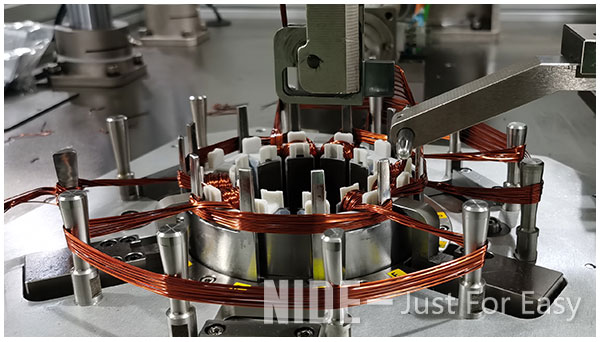

Automatic BLDC Motor Winding Machine Process. 14 Strands Wire Needle Winding Technology For Electric Motorcycle BLDC Motor Manufacturing.

Electric Motorcycle BLDC Motor Multi Strand Winding Machine

The BLDC winding machine combines with the latest needle winding technology and is known for its speed and stability in producing.14 strands wire can be wound at the same time to improve the stator winding speed.

Needle winding machine application:

This stator needle winding machine is suitable for brushless motor manufacturing, used in electric vehicles, electric motorcycles, electric bicycles, electric balance cars and so on.

The automatic needle motor winding machines is high-speed stator winders and is suitable for brushless /BLDC motor stator coil winding,manually loading / unloading,the machine automatically complete mold clamping,winding,wire clamping and cutting,it can achieve multi tapping (set on HMI).The stator slot NO. and turn NO. can be set on HMI.It can do multi strands wire parallel winding, and the machine has remote diagnosis function.

Needle Winding Machine Specification:

| Product name: | BLDC Motor Stator Winding Machine For Electric Motorcycle |

| Winding Method: | Multi-strand needle winding |

| Wire dia.: | 0.25-0.8 mm |

| Winding speed: | 0-350 r/min |

| Needle NO.: | one |

| Stator ID: | 50-180mm |

| Stack length: | 10-180mm |

| Stator OD: | 70-210mm |

| Pole No.: | 4 |

| Air pressure: | 0.5MPa~1 MPa |

| Voltage: | 380V/50HZ three phase four wires |

| Power: | 9.5 KW |

| Weight: | About 600kg |

| Dimension: | 1200L*750W*1900H |

Needle Winding Machine Function And Characteristics:

1.The needle winding machine is able to high efficiency winding stator without leaving any protruding copper wires.

2.The needle winding machine offers an optimum slot filling coefficient and the wire is arranged in a very orderly manner, not randomly like a conventional winding machine.Winding into the lamination stack slot can offers savings of up to 30% in terms of copper wire consumption.

3.The BLDC needle winding machine winds the required number of turns directly into the stator slot.

4.The winding machine provides free programming, so you can decide where to anchor the initial starting wire before winding, whether to run the cycle clockwise or anticlockwise, and all the necessary position changes to complete the process.

5.Our motor winding machine have now been sold more than 50 countries around the world,Nide is the leading motor manufacturing machines supplier from China.

Needle Winding Machine Show Details

Needle Winding Machine Video

![]()

| Contact us

Motor Manufacturing Machine Department