2023-04-17

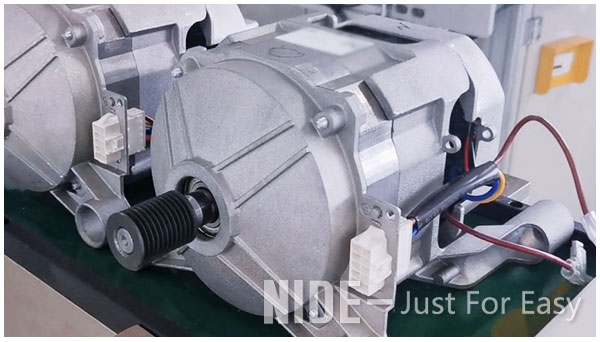

Classification of electric induction and AC motor parts

The classification of motor accessories can be roughly classified according to the components of the induction and AC motor, which can be roughly divided into motor stators, motor rotors, stator windings, motor housings, end covers, motor blades, bearings and other components.

The motor stator is an important part of motors such as generators and starters. The stator is an important part of the motor. The stator is composed of three parts: a stator core, a stator winding and a base. The main function of the stator is to generate a rotating magnetic field, and the main function of the rotor is to be cut by the lines of magnetic force in the rotating magnetic field to generate (output) current.

Motor rotor: It is also a rotating part in the motor. The motor is composed of a rotor and a stator. It is used to realize the conversion device between electrical energy and mechanical energy and mechanical energy and electrical energy. The motor rotor is divided into motor rotor and generator rotor.

Stator windings can be divided into two types, centralized and distributed, according to different coil winding shapes and coil inserting methods. The winding and inserting of the centralized winding is relatively simple, but the efficiency is low and the running performance is poor. Most of the current AC motor stators use distributed windings. According to different models, models and the process conditions of the coil embedding, the motors are designed with different winding types and specifications, so the technical parameters of the windings are also different.

4. Motor housing

Motor housing generally refers to the external housing of all electrical and electrical equipment. The motor shell is a protection device for the motor, and it is made of silicon steel sheet and other materials by stamping and drawing processes. In addition, the surface anti-rust and plastic spraying process can well protect the internal equipment of the motor.

Main functions: dustproof, noise-proof and waterproof.

According to material: metal shell, plastic shell and so on.

According to application: generator shell, starter shell, motor shell for other digital products

5. Motor end cover

The end cover is a back cover installed behind the motor casing, commonly known as "end cover". It is mainly composed of cover, bearing and electric brush. The quality of the end cover directly affects the quality of the motor.

6. Generator blades

The fan blades of the motor are generally located at the tail of the motor and are used for ventilation and cooling of the motor, mainly acting on the tail of the AC motor, or placed in the special ventilation duct of the DC and high voltage motors. The fan blades of explosion-proof motors are generally made of plastic.

According to material: plastic fan blades, cast aluminum fan blades, and cast iron fan blades.

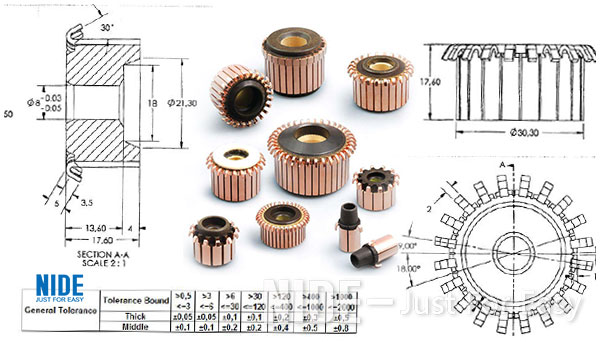

The commutator (collector) is an important part of the DC motor. Its function is to convert the DC current passing through the brush into the alternating current in the winding or the alternating electromotive force in the winding into the DC electromotive force on the brush end.

The commutator includes: mechanical commutator, semi-plastic commutator, and all-plastic commutator.

The commutator used in the starter of an automobile mainly uses a mechanical arch commutator and a plastic commutator.

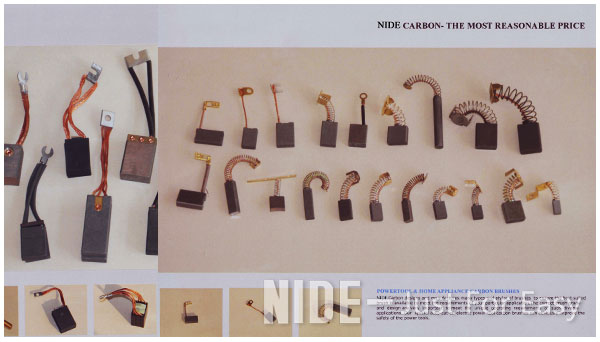

Carbon brush (Carbon brush) is also called electric brush. As a sliding contact, it is widely used in much electrical equipment. The main materials used for carbon brushes are graphite, grease-impregnated graphite, and metal (copper, silver) graphite. A carbon brush is a device that transfers energy or signals between the fixed part and the rotating part of a motor or generator or other rotating machinery. It is generally made of pure carbon plus a coagulant. The appearance is generally a block and it is stuck on a metal bracket. A spring presses it tightly on the shaft. When the motor rotates, the electric energy is sent to the coil through the inverter. Because its main component is carbon, it is called a carbon brush, which is easy to wear. It should be regularly maintained and replaced, and carbon deposits should be cleaned up.

It is an insulating materials, used for various electrical equipment, such as cables and coils. In addition to having good insulation properties and mechanical strength, each has its own characteristics. Motor insulation includes inter-strand, inter-turn, inter-row, inter-layer and absolute insulation of motor coils, various supports or fixations at the ends, insulation of various insulating components, connecting wires and lead wires.

Bearings are an important part of contemporary machinery and equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement, and ensure its rotation accuracy.

According to the different friction properties of the moving elements, bearings can be divided into rolling bearings and sliding bearings. Among them, the rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial size, vibration and noise are larger, and the price is higher.

Rolling bearings are generally composed of four parts: outer ring, inner ring, rolling element and cage. Strictly speaking, it is composed of six parts: outer ring, inner ring, rolling element, cage, seal, and lubricant. Mainly equipped with outer ring, inner ring, and rolling elements can be defined as rolling bearings. According to the shape of the rolling elements, rolling bearings are divided into two categories: ball bearings and roller bearings.

NIDE can supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover, etc.