2023-02-28

The Material and Importance of Carbon Brushes

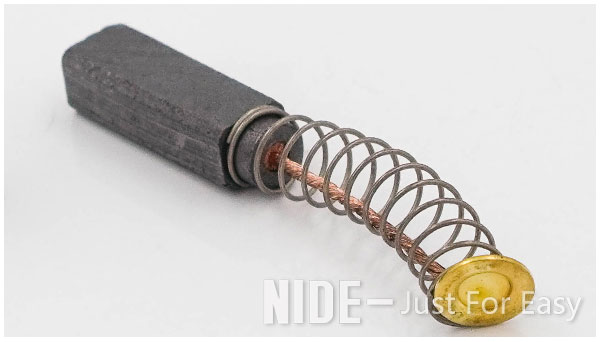

Carbon brushes or electric brushes are widely used in electrical equipment. They are used to transmit signals or energy between the fixed part and the rotating part of some motors or generators. The shape is rectangular, and metal wires are installed in the spring. Carbon brushes are a kind of sliding contact, so it is easy to wear and needs to be replaced regularly and the carbon deposits that have been worn away must be cleaned.

The main component of the carbon brush is carbon. When working, it is pressed by a spring to work on the rotating part like a brush, so it is called a carbon brush. The main material is graphite.

Graphite is a natural element, its main component is carbon, the color is black, opaque, semi-metallic luster, low hardness, can be picked with fingernails, graphite and diamond are both carbon, but their properties are very different , which is due to the different arrangement of carbon atoms. Although the composition of graphite is carbon, it is a high temperature resistant material with a melting point of 3652°C. Using this high temperature resistance property, graphite can be processed into a high temperature resistant chemical crucible.

The electrical conductivity of graphite is very good, surpassing many metals and hundreds of times that of non-metals, so it is manufactured into conductive parts such as electrodes and carbon brushes; the internal structure of graphite determines its good lubricity, and we often use it on rusty doors Putting pencil dust or graphite into the lock will make it easier to open the door. This should be the lubricating effect of graphite.

Carbon brushes are generally used in DC electrical appliances. Brushed motors are composed of a stator and a rotor. In a DC motor, in order to make the rotor rotate, the direction of the current needs to be constantly changed, otherwise the rotor can only rotate half a circle. Carbon brushes play a very important role in DC motors. Carbon brushes conduct current between the moving parts of the motor. This conduction is a sliding conduction that can transfer current from the fixed end to the rotating part of the generator or motor. A carbon frame is composed of several carbon brushes, so this conduction method also makes the carbon brushes easy to wear, and the carbon brushes also change the direction of the current, that is, the role of commutation.

The brushed motor adopts mechanical commutation, the outer magnetic pole does not move and the inner coil moves. When the motor is working, the commutator and the coil rotate together, and the carbon brush and the magnetic steel do not move, so the commutator and the carbon brush produce friction to complete the switching of the current direction.

As the motor rotates, different coils or two different stages of the same coil are energized, so that the two poles of the magnetic field generated by the coil have an angle with the two poles close to the permanent magnet stator, and the power is generated through the repulsion of the same pole and the attraction of the opposite pole to drive the motor to rotate.

Carbon brushes are also used in AC equipment. The shape and material of AC motor carbon brushes and DC motor carbon brushes are the same. In AC motors, carbon brushes are used when some winding rotors need variable speed, such as our commonly used electric drills and polishing machines, and they need to replace carbon brushes frequently.