2023-11-22

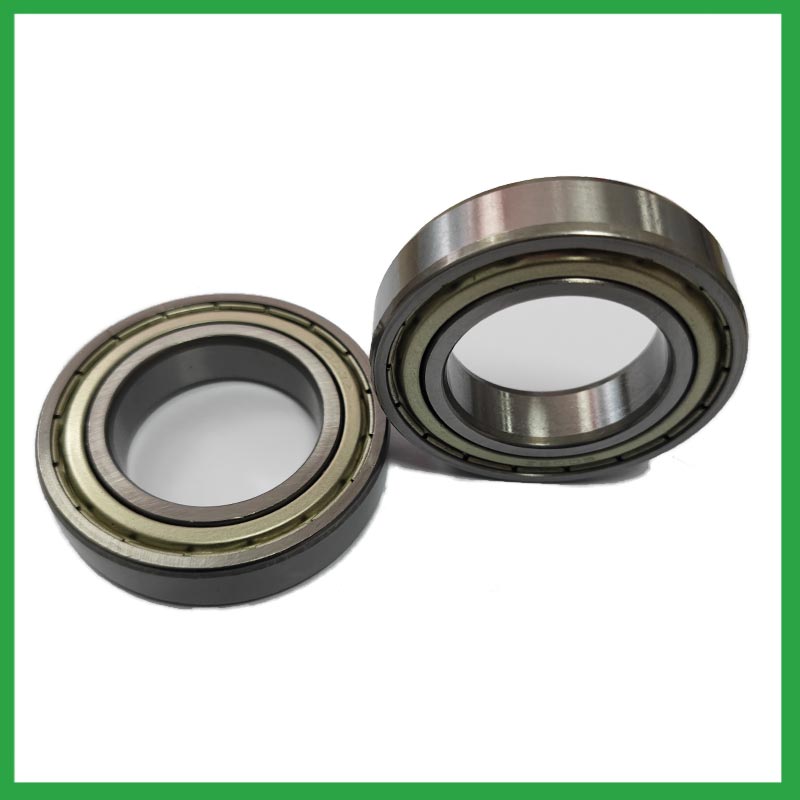

Angular contact ball bearing, one of the two members of the class of rolling, or so-called antifriction, bearings (the other member of the class is the roller bearing). The function of a ball bearing is to connect two machine members that move relative to one another in such a manner that the frictional resistance to motion is minimal. In many applications one of the members is a rotating shaft and the other a fixed housing.

Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing. Make motor, turn to Nide, everything will be easy !

As a high-precision rotating equipment, angular contact ball bearing play an important role in various mechanical manufacturing fields, consisting of precision manufactured components such as inner spherical surfaces, outer spherical surfaces, cages, steel balls, etc. It achieves support and load transfer between the shaft and the shaft seat by rolling the steel ball between the inner and outer spherical surfaces. Ball bearings have advantages such as strong load capacity, high speed, and long service life, and are widely used in important fields such as aerospace, ships, and trains.

angular contact ball bearing are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

| # | angular contact ball bearing Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

1.What maintenance practices are recommended to extend the lifespan of ball bearings and prevent premature failure?

Proper handling and installation of bearings is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

2.How do manufacturers ensure the quality and reliability of angular contact ball bearing through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

3.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

4.What is a ball bearing?

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races. The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other. Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

5.What is the significance of angular contact ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

6.Where can angular contact ball bearing be used?

angular contact ball bearing are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

7.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

8.How do ball bearings provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearings operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

9.Can angular contact ball bearing operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. angular contact ball bearing are comparatively easy to install and require minimal maintenance.

10.Can ball bearings be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations. Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

11.How do different ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearings: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

12.Are there ongoing research and development efforts aimed at improving ball bearing materials, designs, and lubrication techniques?

A custom bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs