2023-11-24

There are a variety of different designs and applications for ball bearing drawer slides, and their design is specific to their industrial application and load type. Some common designs of ball bearings include: Angular Contact Bearings: designed to work under combined radial and axial loads. Axial Bearings: also called thrust ball bearings, these are designed to work under force applied parallel to the bearing’s axis, or thrust loads. Deep-Groove Bearings: designed to carry both radial and light axial loads. Linear Bearings: designed to allow movement in one direction along a linear axis. Self-aligning Ball Bearings: bearings with two sets of balls that are self-aligning and to carry both radial and light axial loads. High-Speed Angular Contact Bearings: another type of precision ball bearing is a high-speed angular contact bearing. As the name implies, high-speed bearings are designed to handle high RPMs with precision and accuracy.

By ceaselessly improve our quality and, our products win high praise for our favorable price, excellent service and timely delivery. No matter before or after sales, from quality to price, we have the complete and professional management system.

ball bearing drawer slides are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

ball bearing drawer slides, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

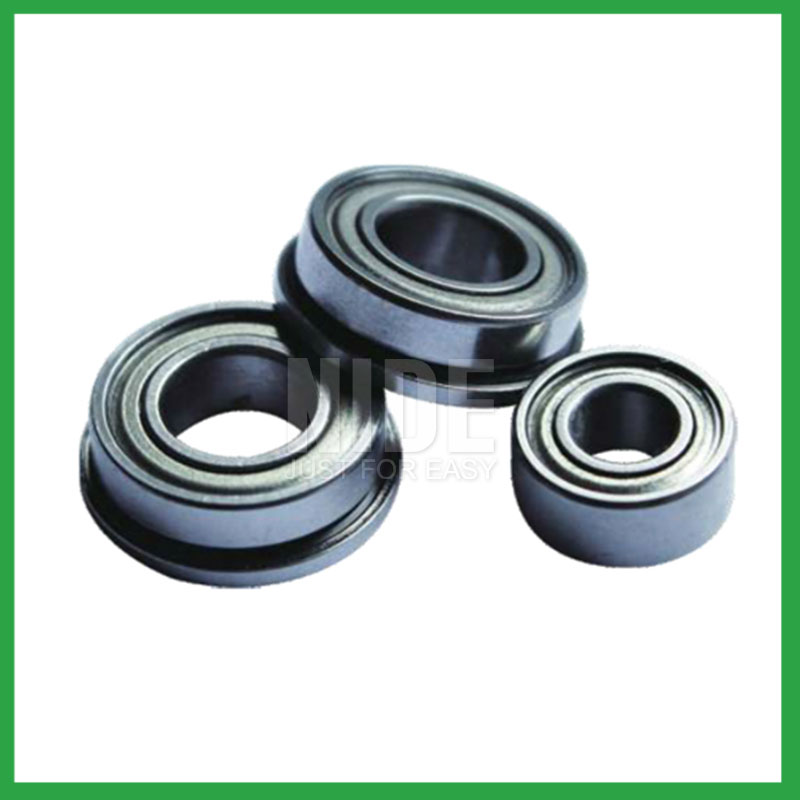

| # | ball bearing drawer slides Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

1.What are the after-sales services available for ball bearing drawer slides?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

2.What are the advancements and innovations in ball bearing drawer slides technology that have emerged in recent years?

Significant advancements have been made in bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

3.How do cage materials and designs impact ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing. Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

4.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

5.How do ball bearings provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearings operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

6.How do sealed ball bearings prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

7.What maintenance practices are recommended to extend the lifespan of ball bearings and prevent premature failure?

Proper handling and installation of bearings is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

8.Are there self-aligning ball bearing drawer slides that accommodate misalignment and shaft deflection in rotating equipment?

These ball bearing drawer slides are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

9.Can ball bearings operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

Ball bearings are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

10.What are the considerations for choosing between open, shielded, or sealed ball bearing drawer slides in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded ball bearing drawer slides can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

11.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

12.Are there ball bearings designed for use in critical medical equipment?

Precision bearings are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life. Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

13.What is the role of ball bearings in reducing friction and energy loss in rotating machinery?

Ball bearings reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

14.How do preloaded ball bearings enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

15.What is the role of ball bearing drawer slides in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the ball bearing drawer slides roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.

16.How do manufacturers ensure the quality and reliability of ball bearing drawer slides through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

Tags: bearing manufacturers