2023-12-05

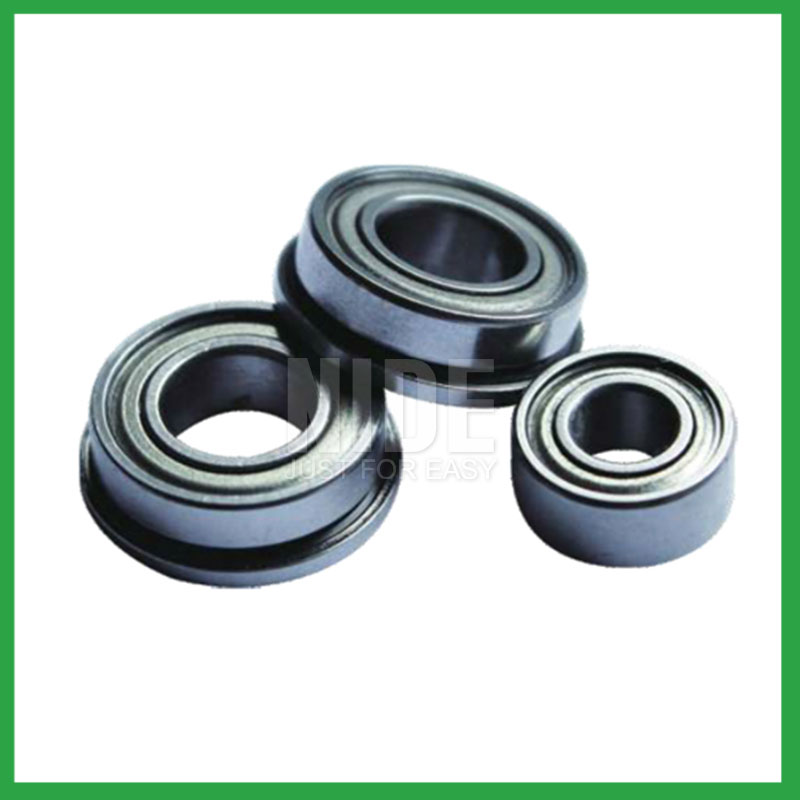

Ningbo Haishunide International Co., Ltd. is specialized in bearings export production selling and after-service. In practice for many years, we established strict quality assurance system. Our products range covers Cylindrical Roller Bearing, Needle Roller Bearing, Tapered Roller Bearing, Spherical roller bearing, Deep Groove Ball Bearing, Angular Contact Ball Bearing,etc.We can do OEM products, and do following drawings.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. Usually one of the races is held fixed. As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling, their coefficient of friction is much lower than that of two flat surfaces rotating against each other.

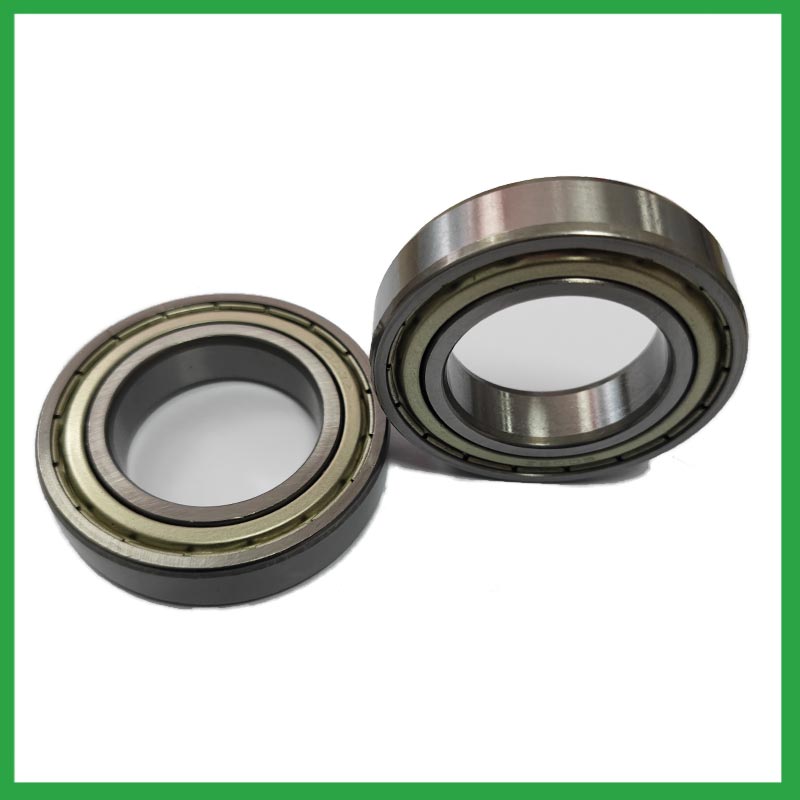

Ball bearings are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

Ball bearings, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

Ball bearings--A Guide to Frequently Asked Questions

1.Are there self-aligning ball bearings that accommodate misalignment and shaft deflection in rotating equipment?

These ball bearings are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

2.What are the considerations for choosing between open, shielded, or sealed ball bearings in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded ball bearings can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

3.What are the after-sales services available for ball bearings?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

4.Are there ongoing research and development efforts aimed at improving ball bearing materials, designs, and lubrication techniques?

A custom bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

5.Where can ball bearings be used?

ball bearings are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

6.What is the production capacity of the factory for ball bearings?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

7.Are there ball bearings designed for extreme temperature environments, such as cryogenic or furnace applications?

High temperature bearings use specialized lubricants to stand up to high temperatures. Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

8.How do preloaded ball bearings enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

9.What anti-corrosion coatings or treatments are available for ball bearings used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether ball bearings are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

10.What are the standard sizes and dimensions of ball bearings?

Ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

11.Can ball bearings operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

Ball bearings are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.