2023-12-05

We has professional technology and rich experience in quality control, customs clearance, commodity inspection, cargo transposition, insurance.We has rich stocks and is able to provide long tern stable supply, including rapid and urgent cargo handing . With companies in Europe, America , Japan and Korea, we are an integrated supplier of bearing, marketing all over the world.

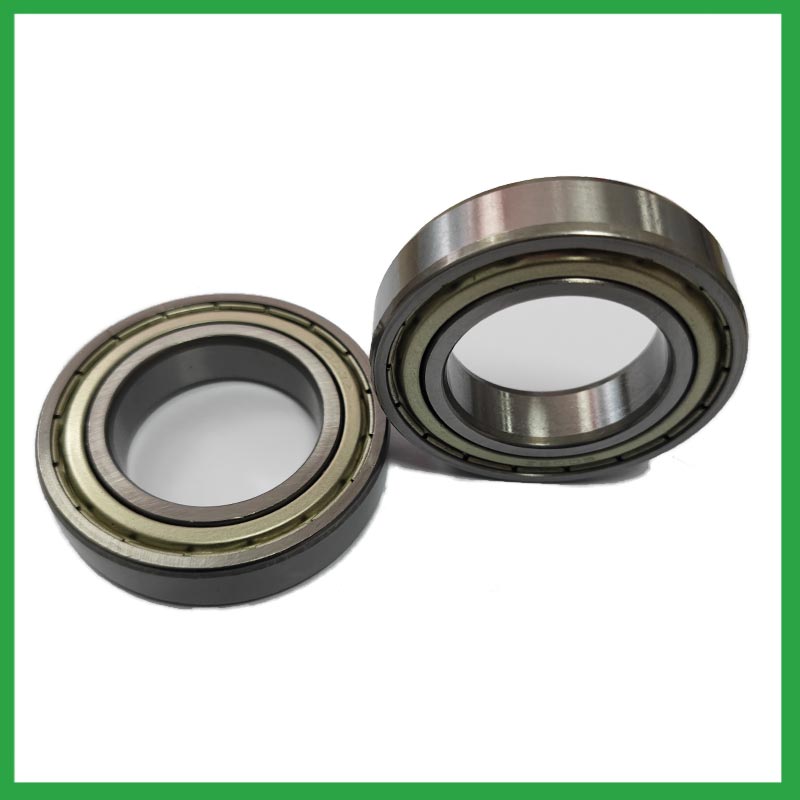

Bearing balls, which play an important role in the engineering field, are an important type of rolling bearing characterized by long service life, strong load capacity, and good sealing performance. In addition to traditional single row ball bearings, there are also various types of double row, four row, and cross roller ball bearings that can meet various engineering needs. At present, with the development of technology, ball bearings are constantly innovating and improving to adapt to more and more complex mechanical equipment applications.

bearing balls are a commonly used mechanical component that can play an extremely important role in most rotating equipment. It is composed of inner and outer spheres, cages, steel balls, and other components. By rolling the steel balls between the inner and outer spheres, it achieves support and load transfer between the shaft and the shaft seat. Ball bearings have the characteristics of simple structure, light weight, and strong load-bearing capacity, and are widely used in fields such as automobiles, motorcycles, electric tools, and household appliances.

bearing balls, known for their excellent performance and wide applicability, are precision mechanical components. Their inner and outer spheres and cages are machined using high-precision machining techniques, and undergo heat treatment and precision balance correction, enabling the bearings to maintain stable operation during high-speed rotation. In addition to being widely used in the industrial field, ball bearings are also often used in high-precision control equipment such as robots and robotic arms.

| # | bearing balls Parameter | Information |

|---|---|---|

| 1 | Material | Chrome steel, stainless steel, ceramics, etc. |

| 2 | Application | Industrial applications, household appliances, transportation, etc. |

| 3 | size(mm) | customize |

| 4 | color | Silver gray, white, gray |

| 5 | types | deep groove ball bearings, angular contact ball bearings, bearing sets, etc. |

bearing balls--A Guide to Frequently Asked Questions

1.What is the significance of bearing balls lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

2.How do different ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearings: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

3.Where can bearing balls be used?

bearing balls are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

4.How do ball bearings contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

5.What are the considerations for choosing between open, shielded, or sealed bearing balls in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded bearing balls can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

6.Do bearing balls come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

7.Are there specific ball bearings designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control ball bearings are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses. Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

8.How do ball bearings provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearings operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

9.What is the typical noise level associated with ball bearings, and how are noise-reduction techniques applied?

To measure in accurate way the bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one. The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

10.Are there miniature ball bearings designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

11.How do manufacturers ensure the quality and reliability of bearing balls through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

12.Can ball bearings be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

13.What is the production capacity of the factory for bearing balls?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

14.Are there hybrid ball bearings that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic Ball Bearings. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

15.Are there ongoing research and development efforts aimed at improving ball bearing materials, designs, and lubrication techniques?

A custom bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

Tags: Ceramic ball bearing