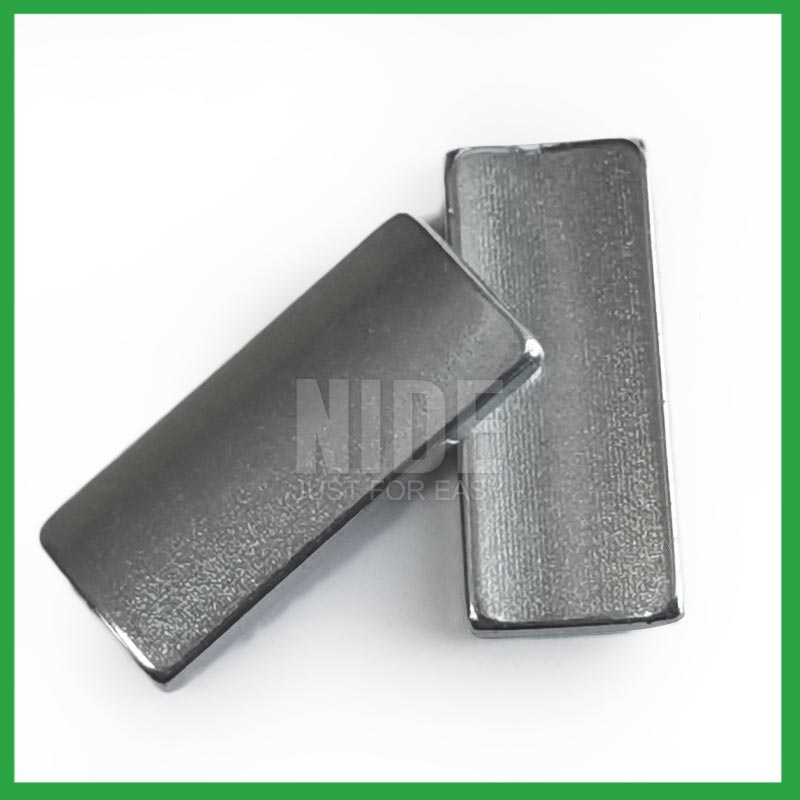

Neodymium magnets, particularly those classified under the N52 grade, are renowned for their exceptional strength and versatility. In the world of motor components manufacturing, such as the products produced by Nide International, these magnets play a crucial role. This article will delve into the characteristics, applications, and differences between Strong Neodymium Magnets N52 and Round NdFeB Countersunk Magnets, highlighting their significance in the motor components industry.

What is Neodymium Magnets?

Neodymium magnets, often abbreviated as NdFeB (Neodymium-Iron-Boron), are a type of rare-earth magnet. They are the strongest type of permanent magnet available commercially. The N52 grade represents the highest magnetic strength currently achievable. These magnets are widely used in various applications due to their high magnetic strength and resistance to demagnetization.

What is N52 Neodymium Magnets?

N52 Neodymium Magnets are characterized by their unparalleled magnetic strength. The "N" denotes neodymium, while the "52" signifies the magnet's maximum energy product, which is measured in Mega-Gauss-Oersteds (MGOe). With an N52 rating, these magnets offer the highest magnetic field strength and pull force among neodymium magnets.

Key Characteristics:

Magnetic Strength: The N52 grade boasts a maximum energy product of 52 MGOe, making it the strongest neodymium magnet available.

Temperature Tolerance: While neodymium magnets generally have a lower Curie temperature than other types of magnets, N52 magnets can operate effectively at temperatures up to 80°C (176°F).

Corrosion Resistance: These magnets often come with protective coatings such as nickel, zinc, or epoxy to prevent corrosion and oxidation.

Dimensional Stability: Despite their high magnetic strength, N52 magnets maintain their dimensional stability and do not exhibit significant physical deformation under normal conditions.

What is Round NdFeB Countersunk Magnets?

Round NdFeB Countersunk Magnets are another type of neodymium magnet, designed specifically with a countersunk hole. This design allows for easy mounting using screws, making them ideal for applications where secure attachment is essential.

Key Characteristics:

Design and Usability: The countersunk hole design facilitates easy and secure mounting on various surfaces, enhancing their practical usability in industrial applications.

Versatility: These magnets are versatile and can be used in various applications, including motor components, sensors, and holding assemblies.

Magnetic Strength: While not always as strong as N52 magnets, Round NdFeB Countersunk Magnets still offer substantial magnetic strength, typically ranging from N35 to N48.

Durability: Like N52 magnets, they are coated to resist corrosion and can endure significant mechanical stress.

Applications in Motor Components Manufacturing

The motor components manufacturing industry, exemplified by companies like Nide International, relies heavily on the unique properties of neodymium magnets. These magnets are integral to the efficiency and performance of various motor components, including electric motors, generators, and actuators.

Role of N52 Neodymium Magnets in Motors:

- High Performance: N52 magnets are used in high-performance motors due to their exceptional magnetic strength. They contribute to higher torque and efficiency, making them ideal for applications requiring robust performance.

- Compact Design: The strong magnetic field allows for the design of smaller and more compact motors without compromising on power. This is particularly beneficial in industries where space is at a premium.

- Energy Efficiency: Motors utilizing N52 magnets tend to be more energy-efficient, as the strong magnetic field reduces energy losses during operation.

Role of Round NdFeB Countersunk Magnets in Motors:

- Secure Mounting: The countersunk design ensures secure mounting within motor assemblies, preventing displacement during operation. This is crucial for maintaining the integrity and reliability of the motor.

- Versatile Applications: These magnets can be used in various motor components, including sensors, holding fixtures, and rotor assemblies. Their versatility makes them a valuable component in motor manufacturing.

- Ease of Assembly: The ease of mounting with screws simplifies the assembly process, reducing production time and costs in motor manufacturing.

How to choose?

When choosing between N52 Neodymium Magnets and Round NdFeB Countersunk Magnets, it's essential to consider the specific requirements of the application.

Magnetic Strength: If the highest possible magnetic strength is required, N52 magnets are the superior choice.Their unmatched energy product makes them suitable for applications demanding maximum performance.

Mounting Requirements: For applications where secure and straightforward mounting is necessary, Round NdFeB Countersunk Magnets offer an advantage. The countersunk hole allows for easy attachment using screws, ensuring stability and reliability.

Application Versatility: Round NdFeB Countersunk Magnets are highly versatile and can be used in various applications beyond motors, such as sensors and holding assemblies. N52 magnets, while extremely powerful, may be over-specified for some applications where such high strength is not needed.

Cost Considerations: N52 magnets, due to their superior magnetic strength, are often more expensive than other grades of neodymium magnets. If budget constraints are a factor, and the application does not require the highest magnetic strength, Round NdFeB Countersunk Magnets or lower-grade neodymium magnets may be more cost-effective.

Conclusion

In the realm of motor components manufacturing, both N52 Neodymium Magnets and Round NdFeB Countersunk Magnets have their distinct advantages. Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing. Make motor, turn to Nide, everything will be easy !Understanding the specific needs of your application will guide you in choosing the appropriate type of neodymium magnet.