2024-07-12

In the quest for sustainable and environmentally friendly manufacturing processes, every component of industrial machinery and consumer products is scrutinized for its environmental impact. Carbon brushes, essential components in electric motors and generators, play a crucial role in the performance and longevity of these machines. But the question remains: Are carbon brushes environmentally friendly? Nide International, a leading name in the industry, explores the environmental aspects of carbon brushes and highlights how the company is addressing sustainability concerns.

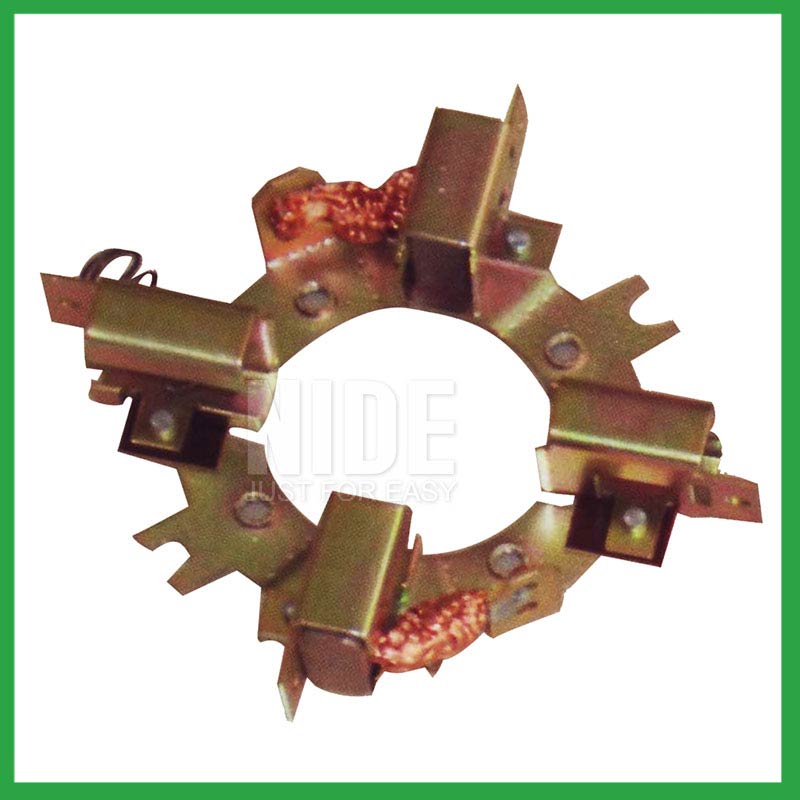

Carbon brushes are small devices that conduct electrical current between stationary wires and moving parts in a motor or generator. They are typically made from graphite or a combination of graphite and other materials, chosen for their good conductivity and lubricating properties. These brushes wear down over time and need to be replaced periodically, which raises questions about their environmental impact.

The primary material used in carbon brushes is graphite, a form of carbon that is abundant and relatively low-impact to mine compared to other materials like rare earth metals. However, the mining and processing of graphite still have environmental consequences, including habitat disruption and carbon emissions.

The manufacturing of carbon brushes involves energy-intensive processes. At Nide International, efforts are made to minimize the environmental footprint of these processes. The company employs energy-efficient technologies and continuously seeks to improve the efficiency of its manufacturing operations to reduce greenhouse gas emissions.

During operation, carbon brushes gradually wear down, creating carbon dust. While this dust is not highly toxic, it can contribute to air and water pollution if not properly managed. Nide International has developed advanced brush designs and materials that minimize dust generation, thereby reducing their environmental impact during use.

The disposal of used carbon brushes poses environmental challenges. Traditional brushes are often discarded in landfills, contributing to waste. Nide International is addressing this issue by promoting recycling programs and researching new materials that can be more easily recycled. The company is also exploring the potential of biodegradable materials for future brush designs.

As a responsible carbon brushes manufacturer, Nide International is committed to minimizing the environmental impact of its products. The company has implemented several initiatives to ensure that its carbon brushes are as environmentally friendly as possible.

Nide International sources graphite and other materials from suppliers that adhere to strict environmental and ethical standards. This ensures that the raw materials used in their brushes are extracted and processed in an environmentally responsible manner.

Nide International’s factory is equipped with state-of-the-art machinery and processes designed to minimize energy consumption. By utilizing renewable energy sources and implementing energy-saving technologies, the company significantly reduces its carbon footprint.

Research and development (R&D) are at the core of Nide International’s strategy for sustainability. The company invests heavily in R&D to develop new materials and manufacturing techniques that are less harmful to the environment. This includes exploring alternatives to traditional graphite that could offer better environmental performance without compromising the functionality of the brushes.

To address the issue of waste, Nide International has established a comprehensive recycling program for used carbon brushes. The company collaborates with customers and recycling facilities to ensure that used brushes are collected, processed, and reused wherever possible. This initiative not only reduces waste but also conserves valuable materials.

Nide International offers OEM/ODM services to provide customized carbon brush solutions that meet specific environmental standards. By tailoring products to the unique needs of each application, the company can optimize the performance and longevity of the brushes, thereby reducing their overall environmental impact.

Investing in environmentally friendly carbon brushes offers several advantages:

The future of carbon brushes lies in continuous innovation and commitment to sustainability. Nide International is at the forefront of this movement, leveraging its expertise and resources to develop brushes that meet the highest environmental standards. By embracing sustainable practices and investing in R&D, the company aims to lead the industry towards a greener future.

Carbon brushes, while essential for many electrical applications, have an environmental impact that cannot be ignored. However, through sustainable practices and innovative solutions, it is possible to minimize this impact. Nide International is dedicated to producing environmentally friendly carbon brushes by implementing energy-efficient manufacturing processes, promoting recycling, and investing in advanced R&D. As the industry continues to evolve, Nide International remains committed to leading the way in sustainability, ensuring that their products not only meet performance standards but also contribute to a healthier planet.