2024-07-23

Commutator DC motors are a fundamental component in many electrical devices and industrial applications. Known for their reliability and efficiency, these motors are used in various applications ranging from household appliances to complex industrial machinery. Nide International, a leading manufacturer and supplier of high-quality DC motors, provides a comprehensive technical guide to understanding commutator DC motors, their benefits, and their applications.

A commutator DC motor is a type of electric motor that uses a commutator to reverse the direction of current flow through the armature windings, ensuring continuous rotation. The commutator, made of segments of conductive material separated by insulating material, works with brushes to maintain electrical contact with the rotating armature.

Armature

The armature is the rotating part of the motor, consisting of coils of wire wound around a core. The current flows through these coils, creating a magnetic field that interacts with the field magnets to produce motion.

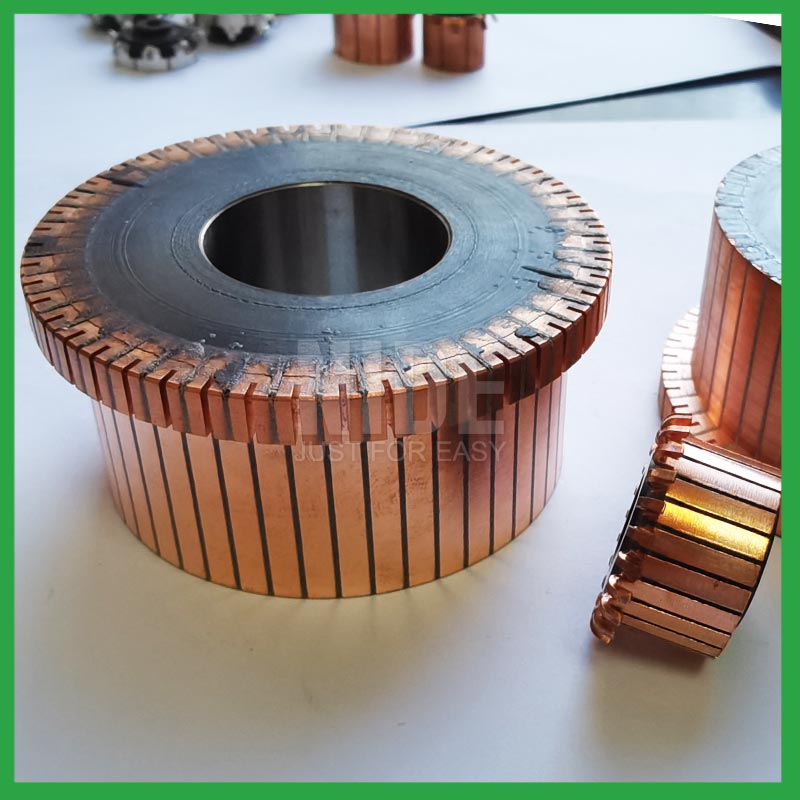

Commutator

The commutator is a segmented cylindrical switch attached to the armature. It reverses the current direction in the armature windings, ensuring that the torque produced is always in the same direction.

Brushes

Brushes are made of carbon or graphite and maintain contact with the commutator, allowing current to flow into the armature windings. They are crucial for the efficient operation of the motor.

Field Magnets

Field magnets provide a constant magnetic field in which the armature rotates. These can be either permanent magnets or electromagnets, depending on the motor design.

High Starting Torque

One of the primary advantages of commutator DC motors is their high starting torque, making them ideal for applications requiring strong initial force, such as electric vehicles and industrial machinery.

Speed Control

Commutator DC motors offer excellent speed control over a wide range. The speed can be adjusted by varying the voltage applied to the armature or by using resistors in the armature circuit, providing flexibility for various applications.

Simplicity and Reliability

These motors have a straightforward design, making them easy to maintain and repair. Their reliable performance and durability make them a preferred choice in many industries.

Cost Performance

Commutator DC motors are cost-effective solutions, offering a balance between performance and price. Their simple construction reduces manufacturing costs, making them an economical choice for many applications.

Commutator DC motors are used in a wide range of applications due to their versatility and reliability. Some common applications include:

Automotive Industry

Used in electric vehicles, windshield wipers, and power windows.

Industrial Machinery

Employed in conveyors, hoists, and cranes for their high starting torque and precise speed control.

Home Appliances

Found in vacuum cleaners, washing machines, and mixers due to their reliable performance and ease of control.

Power Tools

Used in drills, saws, and grinders for their robust performance and durability.

1. Expertise and Experience

Nide International is a renowned manufacturer of commutator DC motors, leveraging years of experience to deliver high-quality products. Their expertise ensures that each motor meets the highest standards of performance and reliability.

2. Advanced R&D

Nide International invests heavily in research and development (R&D) to continuously improve their products and incorporate the latest technological advancements. This commitment to innovation ensures that their motors are always at the forefront of the industry.

3. Customization and OEM/ODM Services

Understanding that different applications have unique requirements, Nide International offers customization and OEM/ODM services. They work closely with clients to design and manufacture motors that meet specific needs, ensuring optimal performance and efficiency.

4. Global Reach and Support

With a robust global supply network, Nide International ensures timely delivery and excellent customer support worldwide. Their commitment to customer satisfaction makes them a trusted partner for businesses around the globe.

Commutator DC motors are essential components in many electrical and industrial applications, offering high starting torque, excellent speed control, and reliable performance. Nide International stands out as a leading manufacturer and supplier of these motors, providing high-quality products backed by advanced R&D and exceptional customer support. Whether you need motors for automotive, industrial, or household applications, Nide International has the expertise and capabilities to meet your needs. Contact Nide International today to learn more about their commutator DC motors and how they can enhance your operations.

Tags: Customized DC Motor Commutator For Treadmill Motor Spare Parts