2024-08-19

In the world of power generation, reliability is non-negotiable. Whether it’s keeping the lights on in a hospital during a power outage or ensuring continuous operation in an industrial facility, the ability of a generator to provide consistent power is critical. A key component in this process is the generator carbon brush, a small but vital part that plays a crucial role in maintaining electrical continuity. Nide International, a leader in electrical components, offers high-quality generator carbon brushes designed to ensure reliable performance and power continuity in various applications. This article explores the importance of generator carbon brushes, their function, and how they contribute to the overall efficiency and reliability of power generation systems.

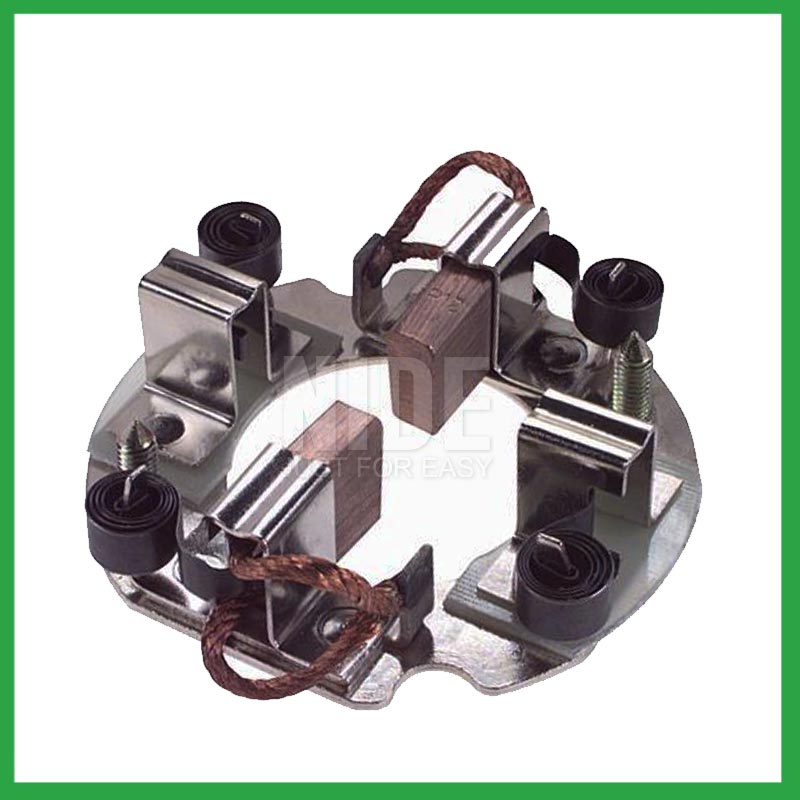

Generator carbon brushes are conductive materials that transfer electricity between the stationary and rotating parts of a generator. They are typically made from carbon or graphite, materials known for their excellent electrical conductivity and ability to withstand high temperatures. In a generator, carbon brushes maintain a constant electrical connection with the rotating commutator or slip ring, enabling the generator to produce a steady flow of electricity.

The function of the carbon brush is critical because any interruption in the electrical connection can lead to power loss, equipment failure, or even damage to the generator. Therefore, the quality and performance of the carbon brush directly impact the reliability and efficiency of the entire power generation system.

High-quality carbon brushes are essential for ensuring the smooth operation of generators. Poor-quality brushes can lead to several issues, including excessive wear, sparking, and electrical noise, all of which can cause interruptions in power supply and reduce the lifespan of the generator. Nide International’s carbon brushes are engineered to provide optimal performance, with features that enhance durability, conductivity, and reliability.

Enhanced Durability: Nide International’s carbon brushes are made from high-grade materials that resist wear and tear, even under harsh operating conditions. This durability ensures a longer service life and reduces the need for frequent replacements, leading to lower maintenance costs.

Superior Conductivity: The carbon brushes from Nide International offer excellent electrical conductivity, ensuring a stable and continuous flow of electricity. This conductivity is crucial for maintaining the efficiency of the generator and preventing power interruptions.

Low Friction and Heat Resistance: Nide International’s carbon brushes are designed to operate with minimal friction, reducing heat generation and wear on the commutator or slip ring. This feature not only extends the life of the brush but also protects the generator’s critical components from damage.

Reliable Performance in Diverse Conditions: Whether used in industrial, commercial, or residential settings, Nide International’s carbon brushes are built to perform reliably across a wide range of operating conditions. Their design ensures consistent performance, even in environments with high humidity, dust, or temperature fluctuations.

Q1: How often should generator carbon brushes be replaced?

A1:

The replacement frequency of generator carbon brushes depends on several factors, including the operating environment, load conditions, and the quality of the brushes. Nide International’s carbon brushes are designed for long service life, but regular inspections are recommended. Generally, it’s advisable to check the brushes every 1,000 to 2,000 operating hours. If the brushes show signs of excessive wear, sparking, or reduced conductivity, they should be replaced to prevent damage to the generator.

Q2: What makes Nide International’s carbon brushes more durable than others?

A2:

Nide International’s carbon brushes are manufactured using high-grade carbon and graphite materials that offer superior resistance to wear and tear. The company’s advanced production techniques ensure that the brushes maintain their shape and conductivity over time, even under challenging conditions. Additionally, Nide International incorporates special treatments that enhance the brushes’ resistance to heat and friction, further extending their lifespan.

Q3: Can Nide International’s carbon brushes be used in generators of different sizes and types?

A3:

Yes, Nide International offers a wide range of carbon brushes designed to fit various generator sizes and types. Whether you need brushes for a small portable generator or a large industrial unit, Nide International can provide the right product to meet your specific needs. The company also offers custom solutions to ensure that their brushes fit perfectly and perform optimally in any application.

Q4: How do Nide International’s carbon brushes contribute to overall generator efficiency?

A4:

Nide International’s carbon brushes contribute to generator efficiency by ensuring a stable and continuous flow of electricity, minimizing energy losses, and reducing wear on the generator’s components. Their superior conductivity and low friction properties help maintain optimal performance, reducing the need for frequent maintenance and minimizing downtime. This results in more efficient power generation and lower operational costs over the long term.

Generator carbon brushes are a small yet vital component in ensuring the reliability and efficiency of power generation systems. Nide International’s high-quality carbon brushes are designed to provide exceptional durability, conductivity, and performance, making them an essential part of any generator setup. By choosing Nide International’s carbon brushes, operators can ensure that their generators deliver consistent power, minimize downtime, and extend the lifespan of critical equipment. In an industry where reliability is paramount, investing in premium carbon brushes from Nide International is a smart choice that pays dividends in both performance and peace of mind.

Products: China Power tool carbon brush sanding polisher machine accessories carbon brush , Metal copper carbon brush for drum washing machine motor