2024-08-19

Plain bearings, also known as bushings, are essential components in many industrial applications, providing smooth, low-friction movement between two surfaces. Unlike rolling bearings, plain bearings have no moving parts, making them simpler and often more durable in certain environments. But can plain bearings withstand extreme conditions such as high temperatures, heavy loads, corrosive environments, or exposure to abrasive particles? The answer is yes—when designed and manufactured to high standards. Nide International, a leader in precision engineering, produces plain bearings that excel in demanding environments, offering reliability and performance where other components might fail.

Plain bearings are typically composed of a single piece of material, often a metal or a composite, that slides against a mating surface. They are used in various applications, from automotive engines to industrial machinery, where they support rotating or sliding shafts, guide components, or absorb shocks. Their simplicity, cost-effectiveness, and ability to handle large loads make them a popular choice in engineering.

The true test of any bearing is its ability to perform under extreme conditions. Nide International has developed plain bearings that are designed to meet the challenges of high temperatures, heavy loads, corrosive environments, and abrasive particles. Here’s how they stand up to these challenges:

One of the most demanding conditions for any bearing is exposure to high temperatures. Many bearings fail when temperatures exceed their material’s limits, leading to deformation, loss of lubrication, or even failure. Nide International’s plain bearings are made from advanced materials such as bronze alloys, composite polymers, and ceramics that can withstand temperatures well beyond those tolerated by standard bearings. These materials maintain their structural integrity and continue to provide low-friction movement, even in environments with extreme heat, such as engines, turbines, or furnaces.

Plain bearings are often chosen for applications where heavy loads need to be supported. In industrial machinery, construction equipment, and transportation, bearings are subjected to high pressures that can lead to wear and deformation. Nide International’s plain bearings are designed to distribute these loads evenly across the bearing surface, reducing stress concentrations and extending the bearing’s lifespan. The materials used, such as high-strength alloys and engineered polymers, ensure that the bearings can handle heavy loads without compromising performance.

In industries such as chemical processing, marine, or mining, bearings are often exposed to corrosive substances that can quickly degrade standard materials. Nide International’s plain bearings are engineered to resist corrosion through the use of special coatings, corrosion-resistant alloys, and composite materials. These bearings are capable of performing reliably in harsh environments, reducing the need for frequent replacements and minimizing downtime.

Abrasive particles, such as dust, sand, or grit, can cause significant wear on bearing surfaces, leading to increased friction, heat, and eventual failure. Nide International addresses this issue by offering plain bearings with self-lubricating properties and wear-resistant surfaces. These bearings are designed to operate effectively in environments where contaminants are present, ensuring smooth operation and a longer service life.

Q1: What materials are used in Nide International’s plain bearings to handle high temperatures?

A1:

Nide International uses advanced materials such as bronze alloys, composite polymers, and ceramics to manufacture plain bearings capable of withstanding high temperatures. These materials maintain their structural integrity and low-friction properties even in extreme heat, making them suitable for applications like engines, turbines, and industrial furnaces.

Q2: How do Nide International’s plain bearings manage heavy loads without failing?

A2:

Nide International’s plain bearings are designed to distribute heavy loads evenly across the bearing surface, reducing stress concentrations that can lead to wear and deformation. The use of high-strength alloys and engineered polymers ensures that these bearings can support heavy loads while maintaining performance and longevity.

Q3: Can Nide International’s plain bearings operate in corrosive environments?

A3:

Yes, Nide International’s plain bearings are engineered to resist corrosion through the use of special coatings, corrosion-resistant alloys, and composite materials. These bearings are ideal for applications in chemical processing, marine environments, and other industries where exposure to corrosive substances is a concern.

Q4: What makes Nide International’s plain bearings suitable for abrasive conditions?

A4:

Nide International’s plain bearings are equipped with self-lubricating properties and wear-resistant surfaces that protect against the effects of abrasive particles. These features allow the bearings to operate smoothly and reliably in environments where dust, sand, or grit may be present, extending their service life and reducing maintenance needs.

Plain bearings are a critical component in many industrial applications, and their ability to withstand extreme conditions is essential for maintaining reliable operation. Nide International’s advanced plain bearings are designed to meet these challenges head-on, offering superior performance in high temperatures, heavy loads, corrosive environments, and abrasive conditions. By choosing Nide International’s plain bearings, industries can ensure that their equipment operates smoothly, efficiently, and with minimal downtime, even in the harshest environments.

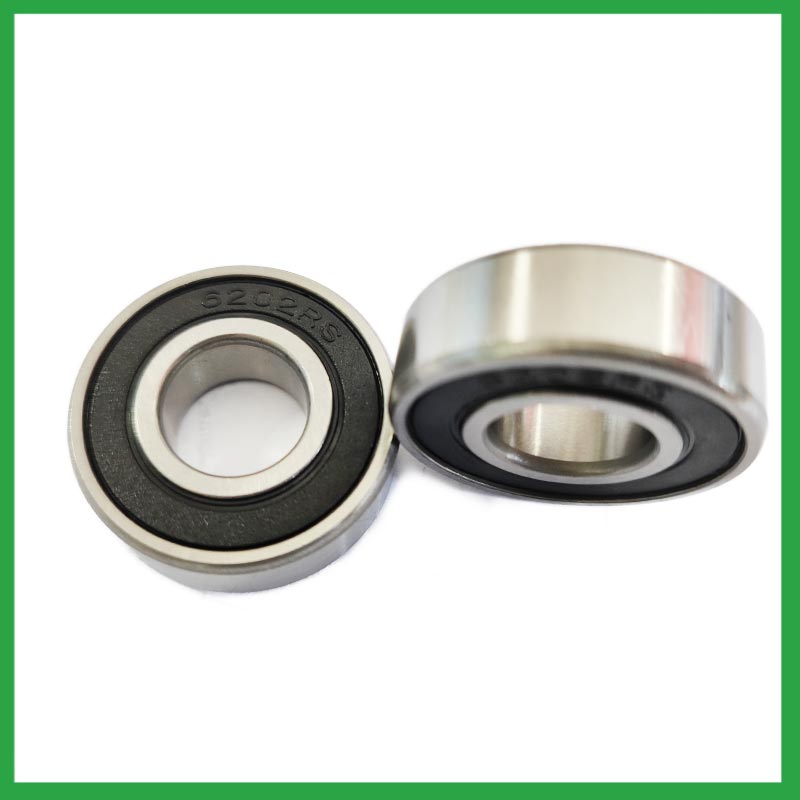

Products: Custom Oil Bushing Bearing Sintered Copper Sleeve , 6008Z Deep groove ball bearings 20x42x8mm