2024-09-23

Electric motors are integral to various industries, from household appliances to heavy-duty machinery, and a critical component that ensures their optimal performance is the carbon motor brush. Among the various types available, the 90930 carbon motor brush is known for its efficiency and durability in motor applications. Nide International, a global leader in motor component manufacturing, specializes in providing high-quality motor brushes that enhance the performance of electric motors. This article provides a technical overview of the 90930 carbon motor brush, its function, applications, and key advantages in different motor systems.

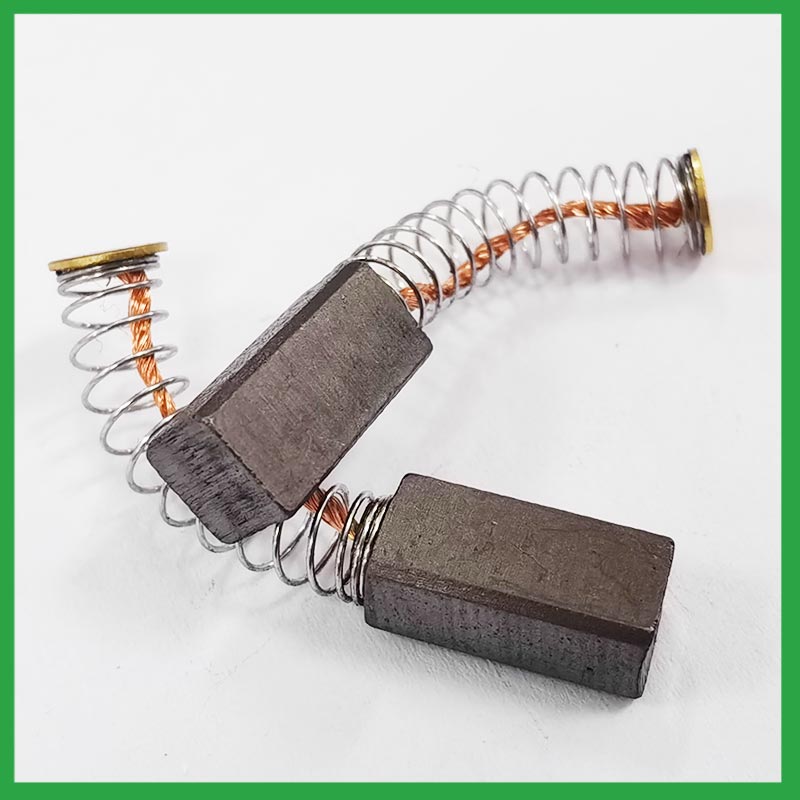

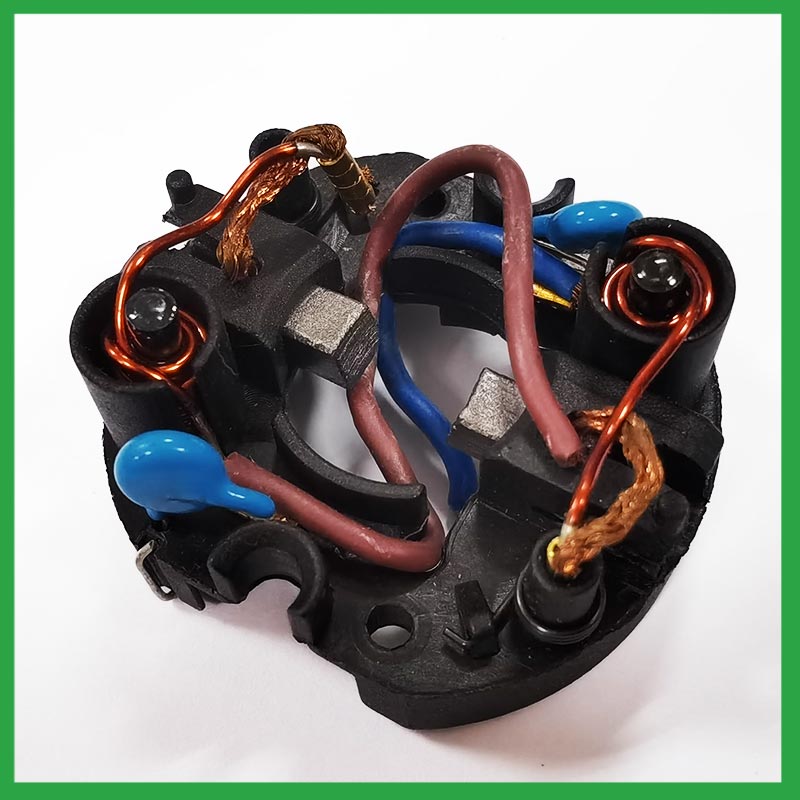

Carbon motor brushes are essential components in electric motors that transmit electrical current between the stationary parts of the motor (stator) and the rotating part (rotor or armature). These brushes are made of a blend of carbon and graphite materials, providing both conductivity and lubricating properties. Over time, the brush wears down due to constant friction, but it is designed to be replaced easily without damaging the motor.

Carbon is the material of choice for motor brushes due to its excellent electrical conductivity and natural lubricating properties, which reduce wear on the commutator or slip rings. Additionally, carbon can withstand high temperatures and is resilient under the frictional forces typically encountered in electric motors, making it an ideal material for motor brushes like the 90930.

The 90930 carbon motor brush is designed to offer superior electrical conductivity, allowing efficient transfer of electricity between the power supply and the motor's rotating elements. This results in improved motor performance, reduced power loss, and increased efficiency across various applications.

Self-lubrication is a key feature of the 90930 carbon brush, minimizing wear and tear on the commutator or slip rings. This reduces maintenance costs and extends the lifespan of the motor, making it a reliable choice for high-performance and long-term applications.

The 90930 carbon motor brush is built for durability. It is engineered to withstand the friction and heat generated in high-speed motor operations, making it highly resistant to wear. This results in fewer brush replacements, longer maintenance intervals, and higher overall reliability in demanding motor applications.

Manufactured with precision by Nide International, the 90930 carbon motor brush is designed to fit perfectly into electric motor systems. Its precise dimensions and high-quality materials ensure consistent performance, minimizing the risk of malfunction or premature wear.

The 90930 carbon brush features a design that reduces operational noise. Its smooth contact with the commutator leads to quieter motor operations, which is particularly important in applications where noise levels are a critical factor, such as in household appliances or medical devices.

In the automotive sector, electric motors are widely used in various components, including starters, alternators, window regulators, and cooling fans. The 90930 carbon motor brush is ideal for these applications due to its durability, excellent conductivity, and ability to withstand harsh operating conditions commonly found in automotive environments.

From vacuum cleaners to washing machines, many household appliances rely on electric motors to function efficiently. The 90930 carbon brush is widely used in household appliances where motor reliability and quiet operation are important.

Power tools such as drills, saws, and grinders use electric motors that require high-performance brushes for efficient and durable operation. The 90930 carbon motor brush offers the wear resistance and conductivity needed to maintain consistent performance in these demanding applications.

Industrial machinery relies on large, high-powered motors for efficient operation. The 90930 carbon motor brush is suitable for use in conveyor systems, compressors, and industrial fans where durability and long service life are essential for minimizing downtime and reducing maintenance costs.

The self-lubricating and wear-resistant properties of the 90930 carbon motor brush contribute to a longer lifespan for both the brush and the motor. By minimizing wear on the commutator, the 90930 reduces the frequency of maintenance and extends the overall life of the motor system.

With superior conductivity and efficient current transfer, the 90930 carbon brush enhances the performance of electric motors, ensuring they run efficiently with minimal power loss. This translates to better energy efficiency and lower operational costs, making it a cost-effective choice for a wide range of applications.

The durability of the 90930 reduces the frequency of brush replacements and maintenance. This results in lower downtime and operational costs, particularly in applications where continuous operation is critical, such as industrial machinery or automotive systems.

The precision manufacturing and self-lubricating properties of the 90930 carbon brush help reduce noise and vibration during motor operation. This feature is particularly beneficial in applications where quiet performance is essential, such as household appliances and medical equipment.

The 90930 carbon motor brush, provided by Nide International, is an exceptional choice for a wide range of electric motor applications. With its high conductivity, durability, self-lubricating properties, and noise reduction capabilities, it delivers enhanced performance and efficiency across industries such as automotive, household appliances, power tools, and industrial machinery. By choosing the 90930 carbon motor brush, users can ensure long-lasting, efficient motor operation while minimizing maintenance costs and downtime.

Products: Electric Drill Motor Carbon Brush 5*8*18mm For Rotary Power Tool , Carbon Brush Holder Set For Home Power Tool Motor