2023-04-17

Switched Reluctance Motor (SRM) is a type of speed-regulating motor developed after DC motor and BLDC. Widely used in household appliances, aviation, aerospace, electronics, machinery and electric vehicles. Ningbo Nide can supply a series of machines for the Switched reluctance motor manufacturing, such as stator production machine line, rotor production line, and switched reluctance motor parts.

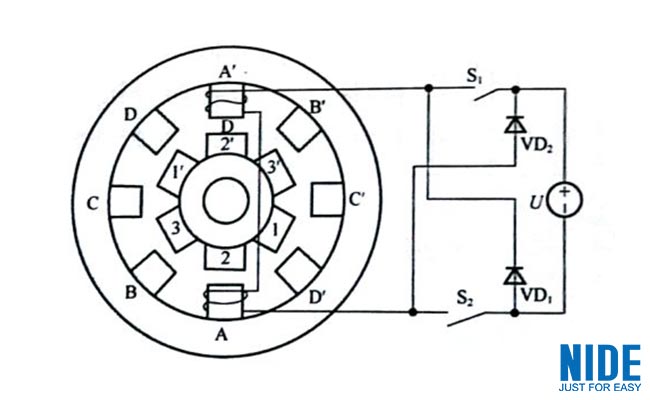

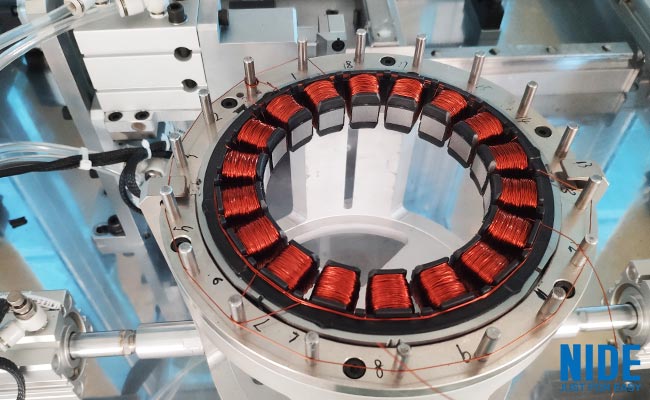

Switched reluctance motor also called as variable reluctance motor is an electric motor operates by producing reluctance torque between iron laminated rotor and energized stator pole. In switched reluctance motors, Stator is similar to brushless dc motor, does not require any permanent magnets, mechanical construction design is simplified but electrical designing becomes complicated.

Number of phase in the motor determine the number of pole in stator. A 3-phase motor has 6 stator poles as 2 opposite ended stator pole forms one phase of the motor. Count of rotor poles is always different from stator poles.

To form the phase of the motor, connection of windings in series on the stator poles is done. Windings used switched reluctance motor are concentrated windings and phase winding resides on stator only. As both stator and rotor are simple in construction and design, faults are less and hence more fault tolerant.

One of the major advantages of switched reluctance motor are they continue to run with disabled or shorted poles but with the reduced smoothness or torque.

Disadvantages of the switched reluctance motor are that difficulty to control, noisy, have torque ripple effect, need shaft sensor for operation. Torque in switched reluctance motor has limitation of maximum allowed current and bus voltage speed.

Considerable efforts are made to improve on the noise characteristics of switched reluctance motor but this can still be a limitation for applications where operating speed range required is very broad. Mechanical design same as switched reluctance motor is used in generator. Such generators run with much higher speed than the conventional ones.

As compared to induction motors, high torque density property, Improved efficiency and more rugged construction have increased the demand for switched reluctance motors.

Another driver for the market is the switch reluctance motor’s application in cost efficiency and energy. The application in high power electronic switches is another reason for growth in the market.

The switch reluctance motor’s suitability to be used in very high temperature ambience is also the factor increasing the use of the switch reluctance motor in the market.

Cheap price is the key reason for the growth of the switch reluctance motor in all the motor types market.

The switched reluctance motor market can be segmented based on the application such as Fuel Pump, Throttle Control, Oil Pump, Vacuum Cleaner, Lawnmower, Washing Machine, Fans, Automatic doors in buildings and vehicles, air conditioning system for passenger trains, vacuum cleaning motor blower, food processor compact drives, Switched reluctance motor also find applications in high volume appliances and appliances which have very high starting torque.

NIDE focus on motor manufacturing solutions,We can provide a range of motor manufacturing machines and accessories, such as

motor manufacturing stand along machine, paper inserting machine ,automatic winding machine, needle winding machine ,stator winding machine, armature winding machine, coil forming machine ,coil lacing machine ,coil insertion machine, fully-auto complete line for armature and stator production, the motor assembly line, commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover, and technical support and consulting, project support and turn-key service for some motor manufacturing.

Our machines are widely used, such as induction motors, brushless motors, universal motors, DC motors, AC motors, single phase motors, three phase motors, shaded pole motors, power tool motors, household appliances motors, general small machinery equipment motors, stepper motors, servo motors, etc.