PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International is located in Ningbo City, Zhejiang Province. It is a high-tech enterprise that integrates research and development, application, production, and sales. Mainly producing high-performance ball bearing,motor cover and lamination,shaft,thermal protector,magnet,fan,carbon brush, etc. The product has a series of characteristics such as oil-free self-lubricating, wear resistance, corrosion and rust resistance, acid, alkali, salt and gas corrosion resistance, no magnetic and electrical insulation, high temperature and cold resistance, light weight, etc. It is widely used in industries such as water pump motor,fan motor,washing machine motor,electric automotive motor,compress motor,electric bicycle motor,air condition motor.

By ceaselessly improve our quality and, our products win high praise for our favorable price, excellent service and timely delivery. No matter before or after sales, from quality to price, we have the complete and professional management system.

| Parameter | Information |

|---|---|

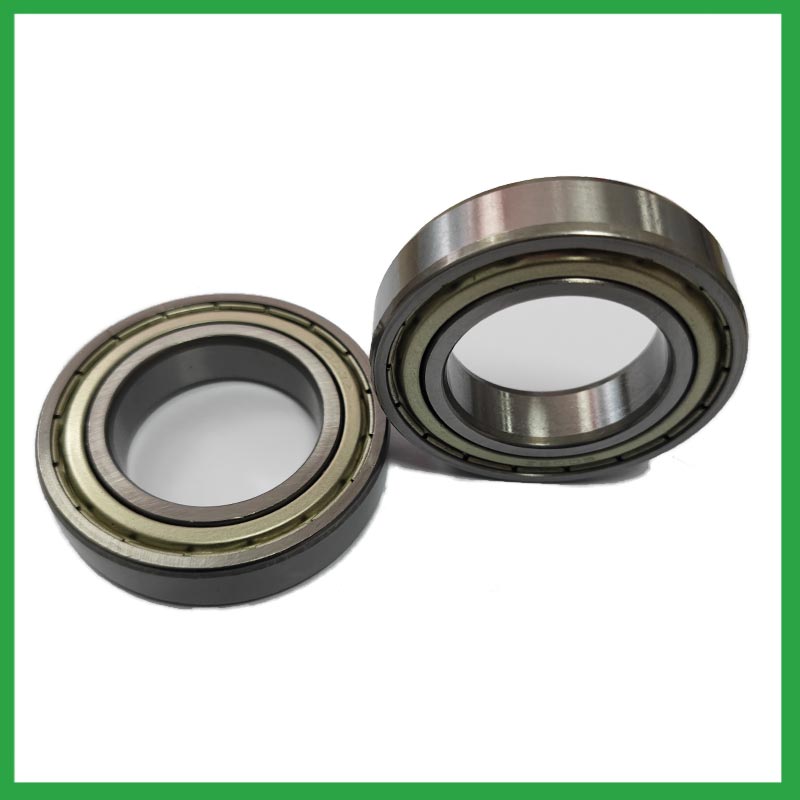

| Product Name | ball bearing floor |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang,China |

| Material | chrome steel, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Oceania,America,Africa |

| Export Country | India,Brazil,South Korea,Paraguay,Morocco,Gabon,Spratly Islands...etc |

| Application | aviation engines, etc. |

| OEM/ODM | Support |

| Size | Customized size |

| Stock | In Stock |

| Feature | Strong carrying capacity,Good wear resistance...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding inserting machine,CE-stator coil lacing machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of ball bearing floor is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing floor---FAQs Guide

2.As a ball bearing floor manufacturer,can you supply samples?

3.What are the common materials used in ball bearing floor manufacturing?

4.Are there hybrid ball bearing floor that combine steel rings with ceramic balls to optimize performance in demanding applications?

5.How do different ball bearing floor designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

6.How do cage designs affect ball bearing floor speed and acceleration capabilities in high-speed machinery?

7.As a ball bearing floor manufacturer,Your product certifications?

8.About ball bearing floor,Will you check the products before shipment?

9.What is the production capacity of the factory for ball bearing floor?

10.What are the advancements and innovations in ball bearing floor technology that have emerged in recent years?

11.What are the ball bearing floor product skill training options?

12.About ball bearing floor,What about the lead time?

1.What are the standard sizes and dimensions of ball bearing floor?

ball bearing floor size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

2.As a ball bearing floor manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

3.What are the common materials used in ball bearing floor manufacturing?

Most ball bearing floor are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

4.Are there hybrid ball bearing floor that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic ball bearing floor. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

5.How do different ball bearing floor designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearing floor: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

6.How do cage designs affect ball bearing floor speed and acceleration capabilities in high-speed machinery?

In high-speed ball bearing floor, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

7.As a ball bearing floor manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

8.About ball bearing floor,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

9.What is the production capacity of the factory for ball bearing floor?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

10.What are the advancements and innovations in ball bearing floor technology that have emerged in recent years?

Significant advancements have been made in ball bearing floor steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

11.What are the ball bearing floor product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

12.About ball bearing floor,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.