PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International was founded in 2010 and is located in the high-tech zone of Ningbo, the industrial center of China. It is very close to Ningbo Port and Shanghai Port. We products products including insulation paper,commutator,fan,thermal protector,shaft,motor cover and lamination, etc The product is widely used in industries such as servo motor,washing machine motor,fan motor,compress motor,electric bicycle motor,air condition motor,water pump motor.

In addition to building machines internally and controlling their quality and service system, we also provide customers with some auxiliary machines outsourced from other professional manufacturers. Its purpose is to reduce additional work for customers and alleviate concerns about quality issues. With excellent service, unique philosophy, professional team, and reliable quality, we have gradually won the trust of global customers.

| Parameter | Information |

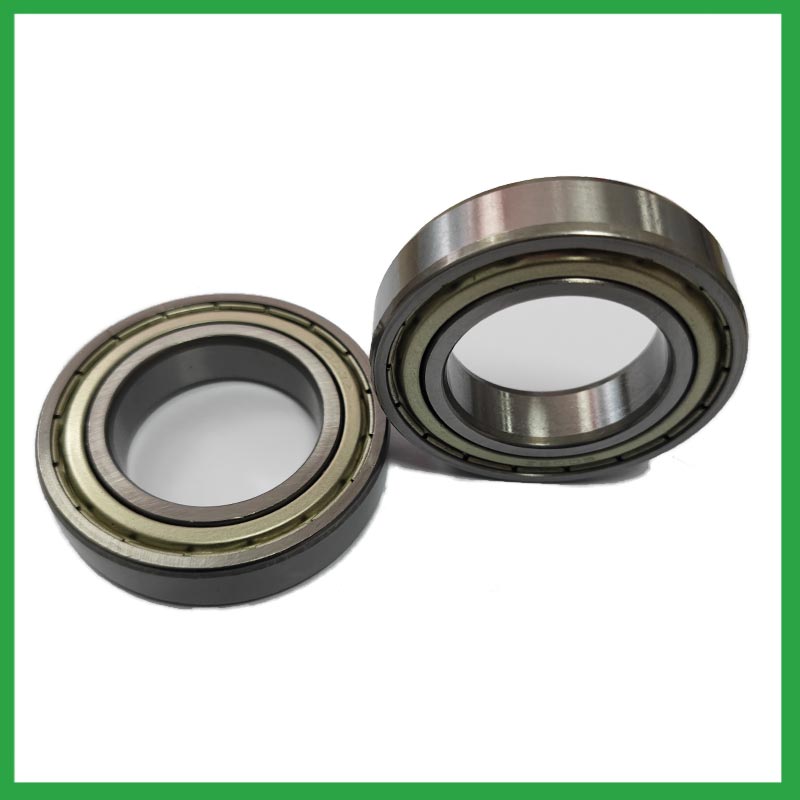

| Product Name | ball bearing hardware |

| Brand Name | Nide |

| Place of Origin | China |

| Type | Ball |

| Material | ceramics, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | small rotary motors,food processing machinery, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Navassa Island,Central African Republic,Western Sahara,Malawi...etc |

| Export region | America,Africa,Asia... |

| Certification | ISO 9001 Certification,CE-stator coil winding machine,CE-stator coil lacing machine,etc |

| Precision Rating | as per customer's requirement |

| Feature | Strong carrying capacity,High speed...etc |

| Packaging Details | Suitable for sea transportation |

| Color | Silver gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

Bearings with ball bearings as rolling elements mainly include adjustable ball bearings,thrust ball bearings,angular contact ball bearings,self-aligning ball bearings, etc.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing hardware---FAQs Guide

2.Can ball bearing hardware be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

3.What are the considerations for choosing between open, shielded, or sealed ball bearing hardware in specific applications?

4.Are there ceramic ball bearing hardware designed for specific applications requiring high-temperature or corrosion resistance?

5.What are the advancements and innovations in ball bearing hardware technology that have emerged in recent years?

6.How do manufacturers ensure the quality and reliability of ball bearing hardware through material selection and precision machining?

7.Are there hybrid ball bearing hardware that combine steel rings with ceramic balls to optimize performance in demanding applications?

8.What maintenance practices are recommended to extend the lifespan of ball bearing hardware and prevent premature failure?

9.Can ball bearing hardware be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

10.Are there miniature ball bearing hardware designed for use in precision instruments and small-scale mechanisms?

11.What are the ball bearing hardware product skill training options?

12.How do sealed ball bearing hardware prevent the ingress of contaminants and extend the bearing's service life?

1.What is the significance of ball bearing hardware lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

2.Can ball bearing hardware be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

3.What are the considerations for choosing between open, shielded, or sealed ball bearing hardware in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded ball bearing hardware can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

4.Are there ceramic ball bearing hardware designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ball bearing hardware are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

5.What are the advancements and innovations in ball bearing hardware technology that have emerged in recent years?

Significant advancements have been made in ball bearing hardware steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

6.How do manufacturers ensure the quality and reliability of ball bearing hardware through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

7.Are there hybrid ball bearing hardware that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic ball bearing hardware. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

8.What maintenance practices are recommended to extend the lifespan of ball bearing hardware and prevent premature failure?

Proper handling and installation of ball bearing hardware is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

9.Can ball bearing hardware be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, ball bearing hardware can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

10.Are there miniature ball bearing hardware designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

11.What are the ball bearing hardware product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

12.How do sealed ball bearing hardware prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the ball bearing hardware. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.