PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd is located in the beautiful sea shore city--Ningbo, taking the advantage of advanced industries hub, perfect supply chain and convenient transportation, and integrating professional team with rich motor manufacturing experience , we focus on supplying the Motor Components One Stop Sourcing Platform to our customers.

Our products include carbon brush,thermal protector,insulation paper,shaft,fan,ball bearing,etc.Apart from these products, we also provide the service for the motor manufacturing technical consultant, project support and turn-key project.

| Parameter | Information |

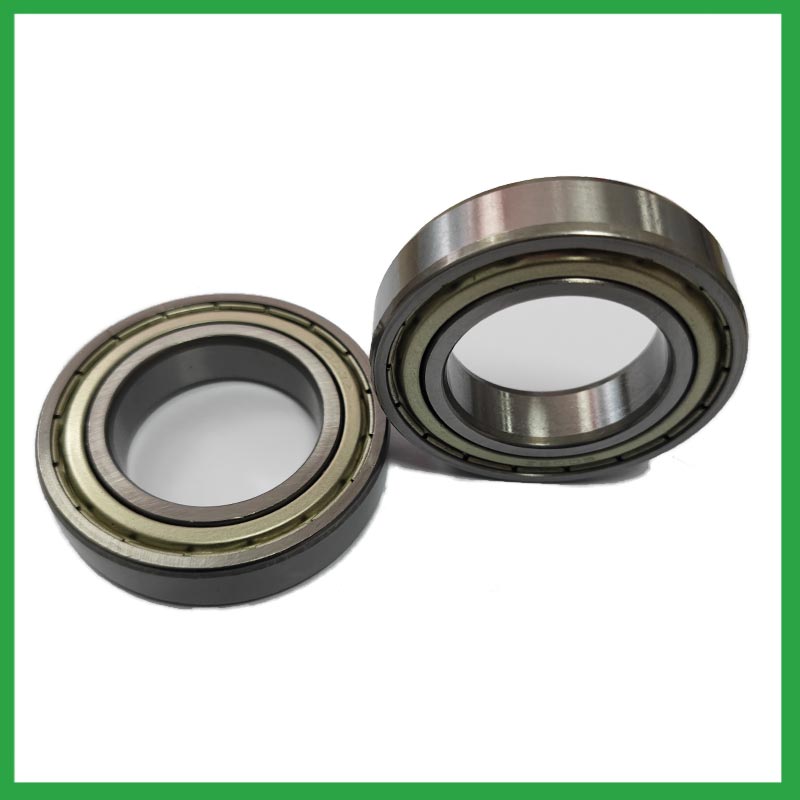

| Product Name | ball bearing in bicycles |

| Brand Name | Nide |

| Place of Origin | China |

| Type | Ball |

| Material | ceramics, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | chemical equipment,automotive engines, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Liberia,Indonesia,New Zealand,Austria...etc |

| Export region | Oceania,Asia,America... |

| Certification | ISO 9001 Certification,CE-stator coil forming machine,ISO9001:2015 certificate,etc |

| Precision Rating | as per customer's requirement |

| Feature | Good wear resistance,High precision...etc |

| Packaging Details | Suitable for sea transportation |

| Color | gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

ball bearing in bicycles require thrust for installation, which can be achieved by using a combination ring made of steel sleeve and transmission rubber, or by using an adjustment plate to tighten the bolt to form a combination ring installation structure.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing in bicycles---FAQs Guide

2.Can ball bearing in bicycles operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

3.What are the advancements and innovations in ball bearing in bicycles technology that have emerged in recent years?

4.What are the ball bearing in bicycles product skill training options?

5.How do ball bearing in bicycles provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

6.Can ball bearing in bicycles operate in high-speed applications, and what design features make them suitable for such conditions?

7.What is the role of ball bearing in bicycles in reducing friction and energy loss in rotating machinery?

8.As a ball bearing in bicycles manufacturer,Your product certifications?

9.How do sealed ball bearing in bicycles prevent the ingress of contaminants and extend the bearing's service life?

10.How do preloaded ball bearing in bicycles enhance rigidity and reduce clearance in high-precision applications?

11.What is the load distribution within a ball bearing in bicycles, and how does it vary between different bearing configurations?

1.How do preload adjustments in ball bearing in bicycles affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.

2.Can ball bearing in bicycles operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

ball bearing in bicycles are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

3.What are the advancements and innovations in ball bearing in bicycles technology that have emerged in recent years?

Significant advancements have been made in ball bearing in bicycles steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

4.What are the ball bearing in bicycles product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

5.How do ball bearing in bicycles provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, ball bearing in bicycles operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

6.Can ball bearing in bicycles operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. ball bearing in bicycles are comparatively easy to install and require minimal maintenance.

7.What is the role of ball bearing in bicycles in reducing friction and energy loss in rotating machinery?

ball bearing in bicycles reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

8.As a ball bearing in bicycles manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

9.How do sealed ball bearing in bicycles prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the ball bearing in bicycles. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

10.How do preloaded ball bearing in bicycles enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

11.What is the load distribution within a ball bearing in bicycles, and how does it vary between different bearing configurations?

The load distribution between the rolling elements and raceway is crucial in performance evaluation of rolling element bearings. Determine the load distribution by measuring the strain response at the bearing surface with a notched housing. Finite element analysis shows that the introduction of notches does not affect the load distribution. An experimental system was developed to investigate the load distribution in a cylindrical roller bearing. The experimental static load distribution agrees well with the theoretical calculation. The dynamic load at specific position of load zone reflects the manufacture difference among rollers and dynamic balance of distributing loads.