PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is a leading bearing manufacturing and trading company committed to providing high-quality and reliable bearing products and excellent services to global customers. Product scope: We offer motor cover and lamination,insulation paper,magnet,thermal protector,shaft,commutator,ball bearing, etc. We also offer customized bearing solutions to meet specific customer requirements and applications. Quality control: We attach great importance to product quality, adhere to international standards and strict quality control processes. Our production facilities are equipped with the most advanced equipment and technology, and our bearings undergo strict testing and inspection to ensure they meet the highest quality standards.

We have obtained ISO9001 certification to ensure consistent quality throughout the entire product line. We strive to ship on time and flexibly process orders to ensure a seamless experience for our esteemed customers. As an international trading company, we cater to global customers. Our products are exported to various countries and regions, and we have established strong partnerships with reliable international logistics companies.

| Parameter | Information |

|---|---|

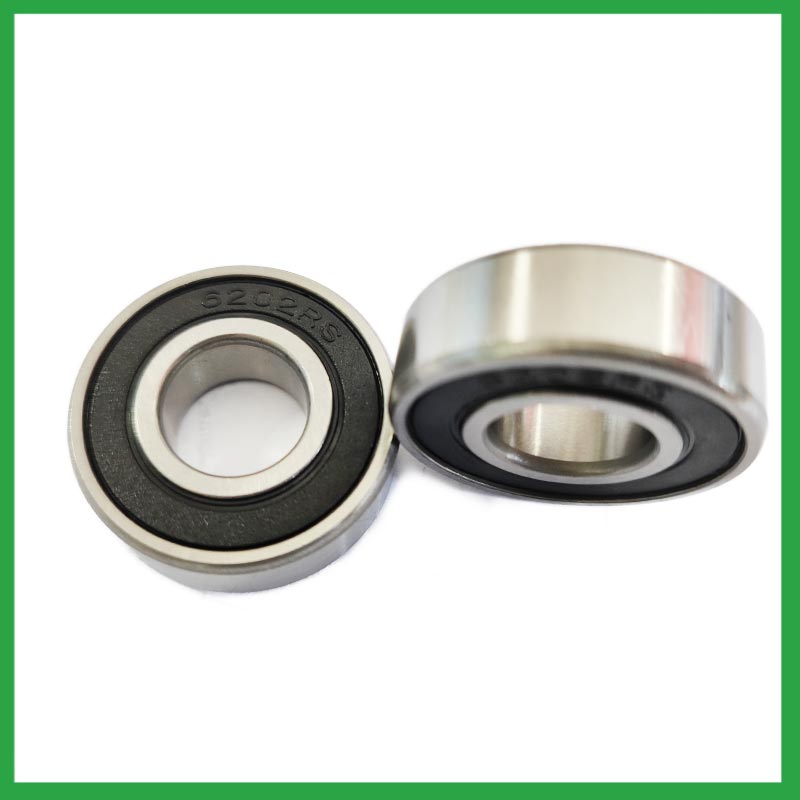

| Product Name | ball bearing invented |

| Brand Name | NIDE |

| Place of Origin | China |

| Material | chrome steel, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | America,Africa,Europe |

| Export Country | India,Brazil,South Korea,Bulgaria,Serbia and Montenegro,Tunisia,Saint Helena...etc |

| Application | high-speed electric tools, etc. |

| OEM/ODM | Yes |

| Size | Customized size |

| Stock | In Stock |

| Feature | Good wear resistance,High speed...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding machine,ISO9001:2015 certificate,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of ball bearing invented is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing invented---FAQs Guide

2.As a ball bearing invented manufacturer,What is your payment method?

3.How do cage materials and designs impact ball bearing invented performance and stability?

4.About ball bearing invented,What about the lead time?

5.What are the considerations for selecting sealed or shielded ball bearing invented to protect against contamination and retain lubrication?

6.Can ball bearing invented be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

7.Can ball bearing invented handle shock loads and high-impact conditions in heavy machinery?

8.How do preload adjustments in ball bearing invented affect their performance and suitability for high-precision tasks?

9.Are there ceramic ball bearing invented designed for specific applications requiring high-temperature or corrosion resistance?

10.About ball bearing invented,Will you check the products before shipment?

11.Where can ball bearing invented be used?

12.What maintenance practices are recommended to extend the lifespan of ball bearing invented and prevent premature failure?

13.What is the significance of ball bearing invented lubrication, and how does it affect bearing lifespan and performance?

1.What anti-corrosion coatings or treatments are available for ball bearing invented used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether ball bearing invented are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

2.As a ball bearing invented manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

3.How do cage materials and designs impact ball bearing invented performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision ball bearing invented directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing.

Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

4.About ball bearing invented,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

5.What are the considerations for selecting sealed or shielded ball bearing invented to protect against contamination and retain lubrication?

First, the environment in which your ball bearing invented operate in can help you identify potential contaminants, allowing you to select your shields or seals accordingly. For example, shielded bearings have a gap that can allow finer contaminants or water from washdown applications to enter the bearing and get into the raceways.The challenge for sealing bearings is to seal the bearing by protecting the bearing from contaminants and running efficiencies.

6.Can ball bearing invented be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, ball bearing invented can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

7.Can ball bearing invented handle shock loads and high-impact conditions in heavy machinery?

As a general rule, ball bearing invented are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

8.How do preload adjustments in ball bearing invented affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.

9.Are there ceramic ball bearing invented designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ball bearing invented are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

10.About ball bearing invented,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

11.Where can ball bearing invented be used?

ball bearing invented are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

12.What maintenance practices are recommended to extend the lifespan of ball bearing invented and prevent premature failure?

Proper handling and installation of ball bearing invented is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

13.What is the significance of ball bearing invented lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.