PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International is located in the beautiful sea shore city--Ningbo, taking the advantage of advanced industries hub, perfect supply chain and convenient transportation, and integrating professional team with rich motor manufacturing experience , we focus on supplying the Motor Components One Stop Sourcing Platform to our customers.

Our products include thermal protector,insulation paper,shaft,commutator,motor cover and lamination,magnet,etc.Apart from these products, we also provide the service for the motor manufacturing technical consultant, project support and turn-key project.

| Parameter | Information |

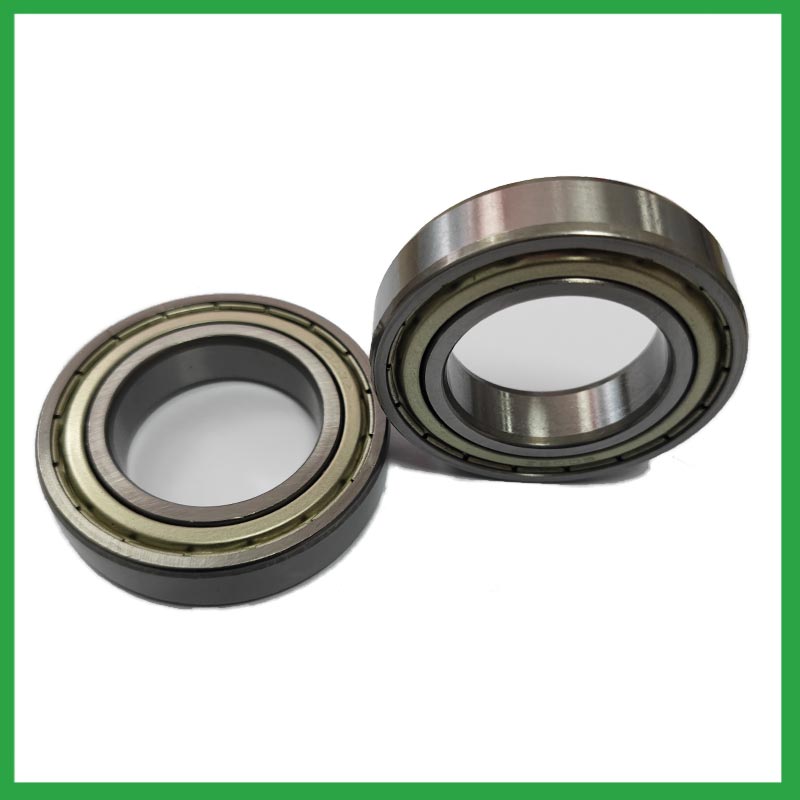

| Product Name | ball bearing rbi |

| Place of Origin | Ningbo,Zhejiang |

| Brand Name | Nide |

| Material | chrome steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | various industrial equipment,chemical equipment, etc. |

| Size(mm) | customize |

| Color | Silver gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-insulation paper inserting machine,CE-stator coil winding machine,etc |

| Feature | Strong carrying capacity,High precision...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

Bearings with ball bearings as rolling elements mainly include deep groove ball bearings,thrust ball bearings,adjustable ball bearings,angular contact ball bearings, etc.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing rbi---FAQs Guide

2.What is the significance of ball bearing rbi lubrication, and how does it affect bearing lifespan and performance?

3.How do different ball bearing rbi designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

4.As a ball bearing rbi manufacturer,What is your payment method?

5.Are there ceramic ball bearing rbi designed for specific applications requiring high-temperature or corrosion resistance?

6.How do preloaded ball bearing rbi enhance rigidity and reduce clearance in high-precision applications?

7.About ball bearing rbi,Will you check the products before shipment?

8.As a ball bearing rbi manufacturer,can you supply samples?

9.Are there ongoing research and development efforts aimed at improving ball bearing rbi materials, designs, and lubrication techniques?

10.What is the role of ball bearing rbi in reducing friction and energy loss in rotating machinery?

11.As a ball bearing rbi manufacturer,How Can We Guarantee Quality?

12.How do manufacturers ensure the quality and reliability of ball bearing rbi through material selection and precision machining?

13.Can ball bearing rbi handle shock loads and high-impact conditions in heavy machinery?

1.What are the common materials used in ball bearing rbi manufacturing?

Most ball bearing rbi are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

2.What is the significance of ball bearing rbi lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

3.How do different ball bearing rbi designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ball bearing rbi: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

4.As a ball bearing rbi manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

5.Are there ceramic ball bearing rbi designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ball bearing rbi are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

6.How do preloaded ball bearing rbi enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

7.About ball bearing rbi,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

8.As a ball bearing rbi manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

9.Are there ongoing research and development efforts aimed at improving ball bearing rbi materials, designs, and lubrication techniques?

A custom ball bearing rbi can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

10.What is the role of ball bearing rbi in reducing friction and energy loss in rotating machinery?

ball bearing rbi reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

11.As a ball bearing rbi manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

12.How do manufacturers ensure the quality and reliability of ball bearing rbi through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

13.Can ball bearing rbi handle shock loads and high-impact conditions in heavy machinery?

As a general rule, ball bearing rbi are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.