PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd is located in Ningbo, Zhejiang Province. Established in 2010, it is a rapidly growing international enterprise. With advanced industrial hubs, complete supply chains, and convenient transportation advantages, combined with a professional team with rich experience in motor manufacturing, we specialize in exporting various bearings to various parts of the world. Our factory has advanced production equipment and testing instruments to ensure that all goods are perfect when received by our customers.

We adhere to strict quality control principles and excellent service. Our main products include insulation paper,fan,thermal protector,ball bearing,carbon brush,commutator, etc. Our products are widely used in fields such as washing machine motor,compress motor,fan motor,electric automotive motor,BLDC motor,water pump motor,servo motor,single and three phase induction motor. With the rapid development of the company, we have gained a good reputation and established long-term business relationships with many customers. So far, Nide has provided products to customers in over 50 countries.

| Parameter | Information |

|---|---|

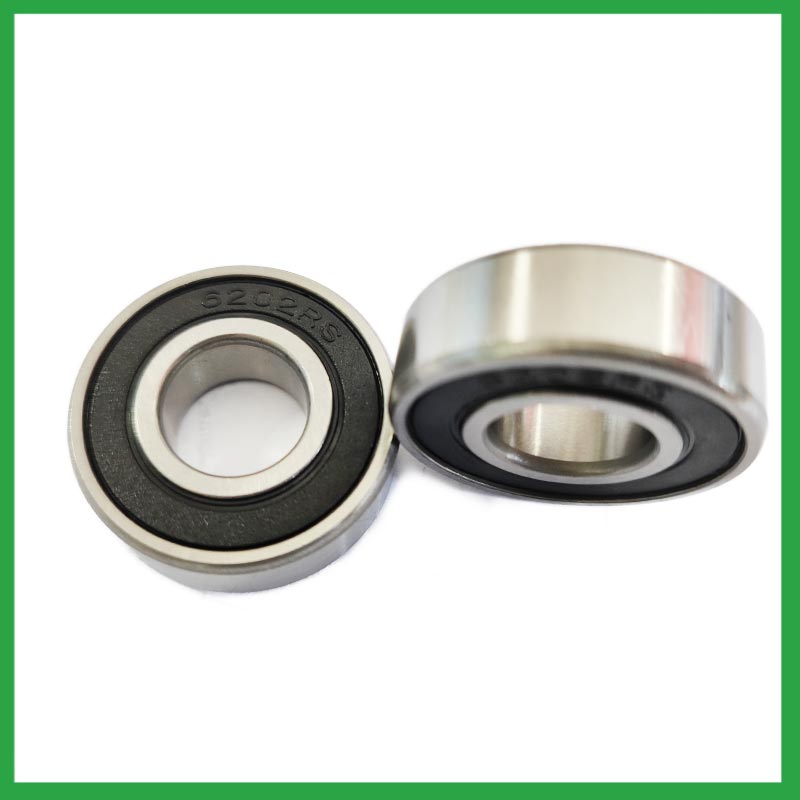

| Product Name | ball bearing screw |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang |

| Material | stainless steel, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Asia,Europe,Oceania |

| Export Country | India,Brazil,South Korea,Greece,Bulgaria,Gabon,Vietnam...etc |

| Application | aviation engines,food processing machinery, etc. |

| OEM/ODM | Acceptatble |

| Size | Customized size |

| Stock | In Stock |

| Feature | Simple structure,High speed...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding inserting machine,CE-insulation paper inserting machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

ball bearing screw can be used in household appliances, such as vegetable cutters,refrigerator door leaf wings,upper and lower pressure rods,barrel machine spindle bearings, etc; It can also be used in industrial fields, such as weighing machines,bearing cabinets,reducers,dishwashers, etc.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball bearing screw---FAQs Guide

2.Where can ball bearing screw be used?

3.About ball bearing screw,Will you check the products before shipment?

4.Are there ceramic ball bearing screw designed for specific applications requiring high-temperature or corrosion resistance?

5.What is the significance of ball bearing screw lubrication, and how does it affect bearing lifespan and performance?

6.About ball bearing screw,What about the lead time?

7.Are there self-aligning ball bearing screw that accommodate misalignment and shaft deflection in rotating equipment?

8.Are there miniature ball bearing screw designed for use in precision instruments and small-scale mechanisms?

9.What are the ball bearing screw product skill training options?

10.What are the advancements and innovations in ball bearing screw technology that have emerged in recent years?

11.About ball bearing screw,Can I add my own logo?

12.Are there ball bearing screw designed for use in critical medical equipment?

13.How do preload adjustments in ball bearing screw affect their performance and suitability for high-precision tasks?

1.Can ball bearing screw operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

ball bearing screw are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

2.Where can ball bearing screw be used?

ball bearing screw are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

3.About ball bearing screw,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

4.Are there ceramic ball bearing screw designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ball bearing screw are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

5.What is the significance of ball bearing screw lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

6.About ball bearing screw,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

7.Are there self-aligning ball bearing screw that accommodate misalignment and shaft deflection in rotating equipment?

These ball bearing screw are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

8.Are there miniature ball bearing screw designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

9.What are the ball bearing screw product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

10.What are the advancements and innovations in ball bearing screw technology that have emerged in recent years?

Significant advancements have been made in ball bearing screw steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

11.About ball bearing screw,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

12.Are there ball bearing screw designed for use in critical medical equipment?

Precision ball bearing screw are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life.

Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

13.How do preload adjustments in ball bearing screw affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.