PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-TS-84

Categoryes: Carbon brush

Our graphite carbon brushes are mainly widely used in electrical motor equipment. They are used to transmit signals or energy to the fixed and rotating parts of some motors or generators. The shape is rectangular, and the metal wire is installed in the spring. The carbon brush is A kind of sliding contact, so it is easy to wear and needs to be replaced and cleaned regularly.

Carbon brushes play a very important role in DC motors. Carbon brushes conduct current between the moving parts of the motor. This conduction is a sliding conduction that can transfer current from the fixed end to the rotating part of the generator or motor. A carbon frame is composed of several carbon brushes, so this conduction method also causes the carbon brushes to be easily worn out, and the carbon brushes also change the direction of current, that is, the effect of commutation.

Carbon brushes are also used in AC equipment. The shape and material of the carbon brushes of AC motors are the same as those of DC motors. In AC motors, there are wound rotors and variable speeds are needed. Carbon brushes are needed, such as our commonly used hand drills and polishing. The machine also needs to change the carbon brush frequently, and its function is also very important.

The main component of a carbon brush is carbon, and it works on a rotating part like a brush when it is pressed by a spring, so it is called a carbon brush. The main material is graphite.

Graphite is a natural element, its main component is carbon, the color is black, it is opaque, has a semi-metallic luster, is not high in hardness, and can be pulled with a nail. The composition of graphite and diamond is carbon, but the properties are very different. This is due to the different arrangement of carbon atoms.

Although graphite is composed of carbon, it is a high temperature resistant material, and its melting point reaches 3652°C. With this high temperature resistant feature, graphite can be processed into a high temperature resistant chemical utensil crucible.

The conductivity of graphite is very good, more than many metals, hundreds of times that of non-metals, so it is made into conductive parts such as electrodes and carbon brushes.

The internal structure of graphite determines its good lubricity.

Technical requirement

|

Material |

Model |

resistance |

Bulk density |

Rated current density |

Rockwell hardness |

loading |

|

Graphite and Electrographite |

D104 |

10±40% |

1.64±10% |

12 |

100(-29%~+10%) |

20KG |

|

D172 |

13±40% |

1.6±10% |

12 |

103(-31%~+9%) |

20KG |

|

|

Advantage: good lubricity and duration |

||||||

|

Application of D104: suitable for 80-120V DC motor, small water turbine generator motor and turbine generator motor |

||||||

|

Application of D172:: suitable for big type water turbine generator motor and turbine generator motor

|

||||||

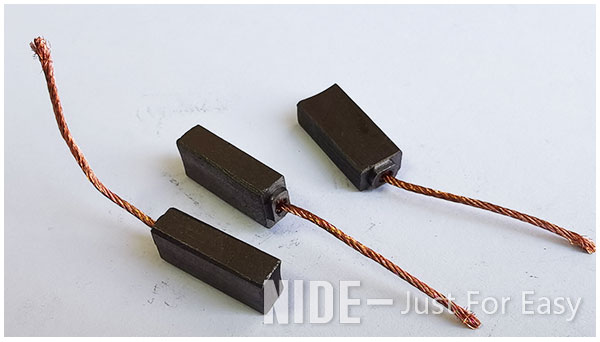

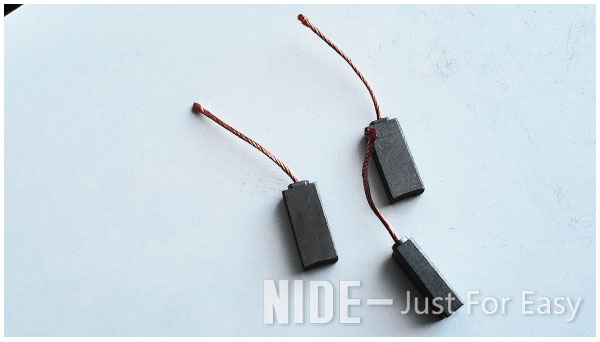

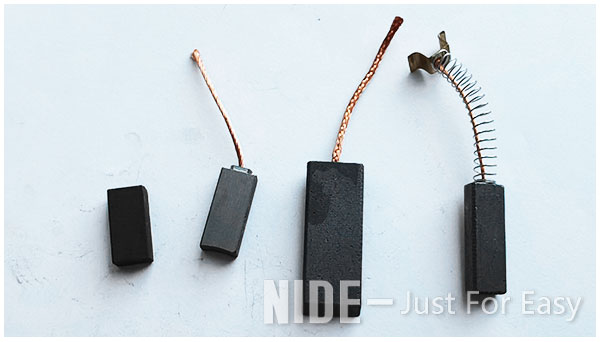

Picture show

Carbon brush features

1) Good quality

2) small spark

3) low noise

4) long duration

5) good lubrication performance

6) good electric conductivity

If possible, it will better if customer could send us samples.

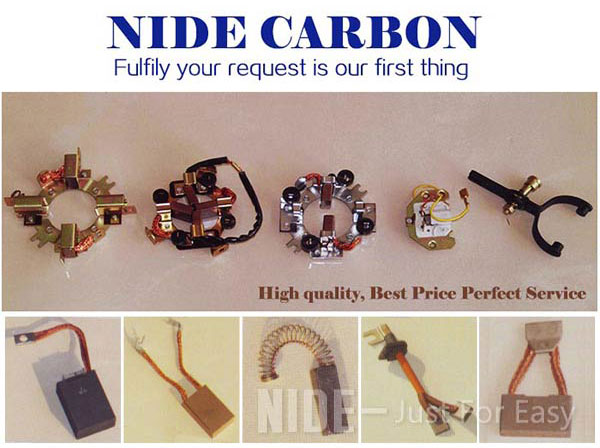

We can produce a wide range of carbon brush. Our carbon brush is widely suitable for automotive industry, household appliances, hammers, planers and etc. We could customize carbon brush for our customer and directly supply our carbon brushes to more than 50 countries around the world.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com