PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International was established in 2010. We produce insulation paper,motor cover and lamination,commutator,carbon brush,shaft,ball bearing,thermal protector and other products. Our unwavering commitment to quality has been recognized by the National Testing Center and the Zhejiang Provincial Testing Center. We adhere to ISO 9001:2015 and CE statior standards, prioritize quality, and operate with integrity.

We prioritize quality and first-class service, constantly pursuing perfection. We have a deep understanding of the precise needs of our customers, and our important motor component manufacturing network and strict quality control system enable us to provide high-quality products to customers at reasonable prices.

| Parameter | Information |

|---|---|

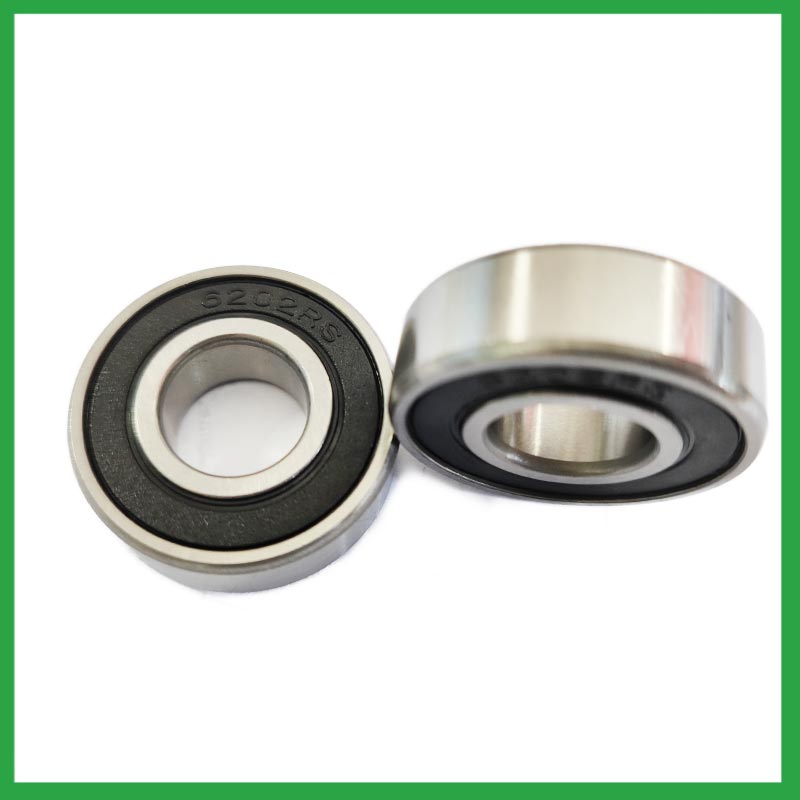

| Product Name | ball type bearing |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang,China |

| Material | ceramics, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Oceania,Asia,Africa |

| Export Country | India,Brazil,South Korea,Papua New Guinea,Bahrain,Mayotte,Niue...etc |

| Application | fan electric motor, etc. |

| OEM/ODM | Support |

| Size | Customized size |

| Stock | In Stock |

| Feature | Low Noise,High precision...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding machine,CE-stator coil lacing machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of ball type bearing is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ball type bearing---FAQs Guide

2.Do ball type bearing come in various tolerance classes?

3.How do preloaded ball type bearing enhance rigidity and reduce clearance in high-precision applications?

4.What maintenance practices are recommended to extend the lifespan of ball type bearing and prevent premature failure?

5.What is the typical noise level associated with ball type bearing, and how are noise-reduction techniques applied?

6.What are the ball type bearing product skill training options?

7.How do manufacturers ensure the quality and reliability of ball type bearing through material selection and precision machining?

8.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

9.As a ball type bearing manufacturer,How Can We Guarantee Quality?

10.What anti-corrosion coatings or treatments are available for ball type bearing used in marine or outdoor applications?

11.As a ball type bearing manufacturer,can you supply samples?

12.What are the after-sales services available for ball type bearing?

13.What are the considerations for selecting sealed or shielded ball type bearing to protect against contamination and retain lubrication?

1.About ball type bearing,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

2.Do ball type bearing come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

3.How do preloaded ball type bearing enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

4.What maintenance practices are recommended to extend the lifespan of ball type bearing and prevent premature failure?

Proper handling and installation of ball type bearing is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

5.What is the typical noise level associated with ball type bearing, and how are noise-reduction techniques applied?

To measure in accurate way the ball type bearing noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one.

The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

6.What are the ball type bearing product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

7.How do manufacturers ensure the quality and reliability of ball type bearing through material selection and precision machining?

High-precision measuring instruments, such as micrometers and gauges, are used to check the dimensions of the rings and balls to ensure they meet tight tolerances. Surface Finish Inspection: Surface finish is assessed using profilometers to ensure the required smoothness and low friction characteristics.

8.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a ball type bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

9.As a ball type bearing manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

10.What anti-corrosion coatings or treatments are available for ball type bearing used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether ball type bearing are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

11.As a ball type bearing manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

12.What are the after-sales services available for ball type bearing?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

13.What are the considerations for selecting sealed or shielded ball type bearing to protect against contamination and retain lubrication?

First, the environment in which your ball type bearing operate in can help you identify potential contaminants, allowing you to select your shields or seals accordingly. For example, shielded bearings have a gap that can allow finer contaminants or water from washdown applications to enter the bearing and get into the raceways.The challenge for sealing bearings is to seal the bearing by protecting the bearing from contaminants and running efficiencies.