PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

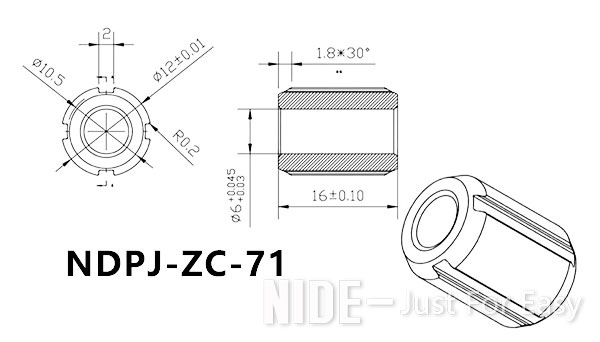

Model:NDPJ-ZC-71

Oil-impregnated bearings have the characteristics of low cost, vibration absorption, low noise, and no need to add lubricating oil during a long working time, and are especially suitable for working environments that are not easy to lubricate or do not allow oil to be dirty.

Categoryes: Ball bearing

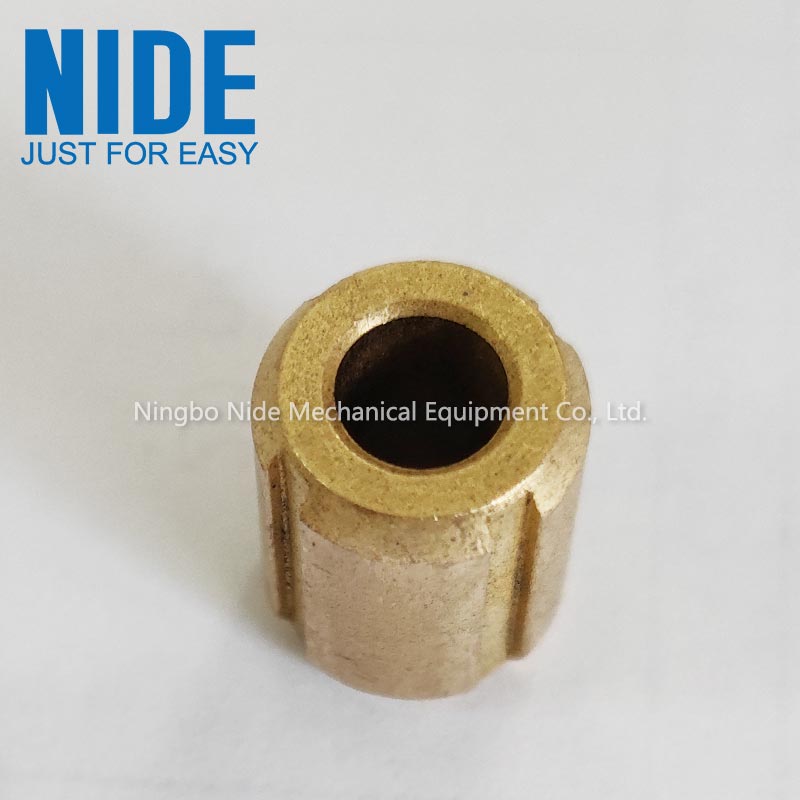

Oil Impregnated Copper Bearings Powder Metallurgy Porous Bearing Bushing

Oil-Impregnated Bearings Features

Oil-impregnated bearings, namely porous bearings, use metal powder as the main raw material and use powder metallurgy to produce a sintered body. It is inherently porous and has the number and size of pores that can be adjusted freely during the manufacturing process. , Shape and distribution, etc. The porous nature of the material can be used to fill the pores with lubricating oil.

Oil-impregnated bearings have the characteristics of low cost, vibration absorption, low noise, and no need to add lubricating oil during a long working time, and are especially suitable for working environments that are not easy to lubricate or do not allow oil to be dirty. Porosity is an important parameter of oil-bearing bearings. Oil-impregnated bearings working at high speeds and light loads require high oil content and high porosity; oil-impregnated bearings working at low speeds and heavy loads require high strength and low porosity.

Oil-impregnated bearings have low manufacturing costs, easy use, excellent wear resistance, seizure resistance, and friction resistance. They can achieve high mechanical performance without maintenance. So it has been widely used, and now it has become an indispensable basic part for the development of various industrial products such as automobiles, home appliances, audio equipment, office equipment, agricultural machinery, and precision machinery.

Oil-Impregnated Bearings Parameters

| Product name: | Copper-iron oil-impregnated bearing/Powder metallurgy bearing bushing |

| Inner diameter: | 6mm |

| Outer diameter: | 12mm |

| Height: | 16mm |

| Thickness: | 6mm |

| Weight: | 0.1kg |

| Material: | tin bronze |

| Production process: | powder metallurgy with oil |

| Load direction: | radial/thrust |

| Bearing mechanism: | solid friction |

| Lubricant: | solid lubrication/no lubrication |

| Lubrication status: | boundary lubrication/fluid film lubrication |

Oil-Impregnated Bearings Picture

NIDE can produce various types of copper sleeves: self-lubricating copper sleeves, powder metallurgy copper sleeves, oil-containing copper sleeves, oil-free self-lubricating copper sleeves, inlaid graphite copper sleeves, bimetallic copper sleeves, bronze-based copper sleeves, British copper sleeves, Self-lubricating gasket. According to the material, there are iron, tin bronze, iron-copper alloy. According to the shape, there are straight, flange, spherical, etc. According to the purpose, there are electromechanical oil-impregnated bearings, cylinder sliding oil-impregnated bearings, stationery sliding oil-impregnated bearings, etc. We can customize the copper sleeve according to customer needs, if you need it, please contact us in time.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com