PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International is a professional manufacturer engaged in bearing research and sales. The factory covers an area of over 9000 square meters and has over 100 employees. The company has modern production equipment and advanced testing instruments. We produce deep groove ball bearings, spherical roller bearings, fan,shaft,thermal protector,ball bearing,carbon brush,motor cover and lamination, etc. The bearing accuracy is P0, P6, P5, P4 levels, widely used in water pump motor,BLDC motor,compress motor,electric automotive motor,fan motor,electric bicycle motor,washing machine motor,single and three phase induction motor. Passed ISO9001:2015 and CE status.

We adopt first-class production equipment and a comprehensive testing system, and hire excellent technical personnel for operation and management. Our bearings are now very popular in the United States, Canada, Türkiye, Russia, Argentina Chad,Ecuador,Peru and other countries and regions.Nide wishes is to provide world wide customers with one-stop service for the motor manufacturing.

| Parameter | Information |

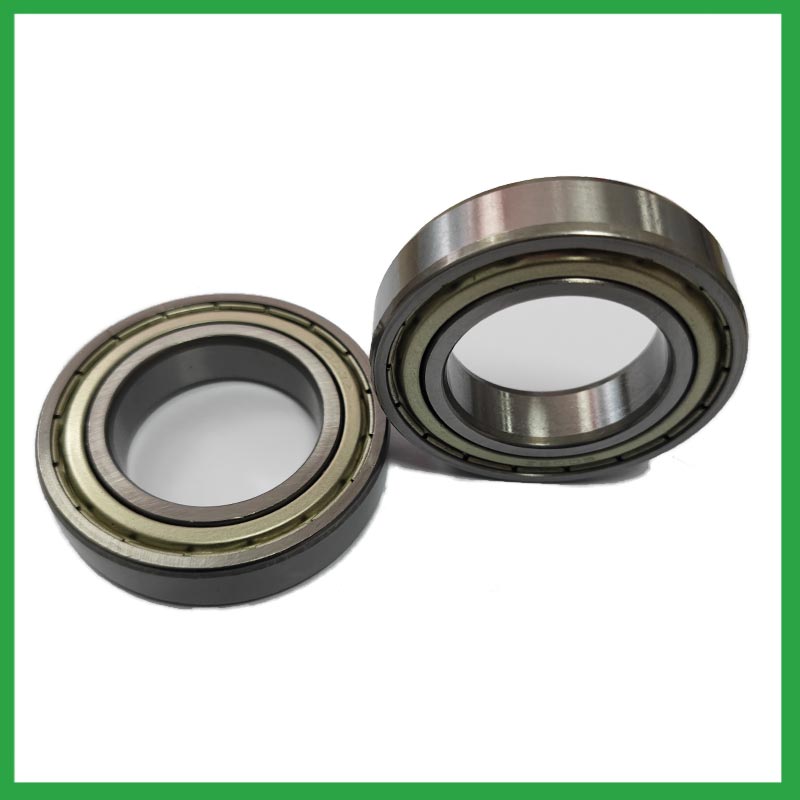

| Product Name | ceiling fan ball bearing |

| Place of Origin | Ningbo,Zhejiang,China |

| Brand Name | Nide |

| Material | chrome steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | machine tools, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil winding machine,CE-stator coil forming machine,etc |

| Feature | High speed,High precision...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

ceiling fan ball bearing is a component with a ball as the rolling element, consisting of an inner ring, an outer ring, and a ball. They form a closed raceway between the rings, and the ball rolls through a curved surface in the raceway.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

ceiling fan ball bearing---FAQs Guide

2.How do different ceiling fan ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

3.Do ceiling fan ball bearing come in various tolerance classes?

4.What are the ceiling fan ball bearing product skill training options?

5.What is the role of ceiling fan ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

6.What are the advancements and innovations in ceiling fan ball bearing technology that have emerged in recent years?

7.What is the production capacity of the factory for ceiling fan ball bearing?

8.Are there ceramic ceiling fan ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

9.How do ceiling fan ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

10.Are there ongoing research and development efforts aimed at improving ceiling fan ball bearing materials, designs, and lubrication techniques?

11.How do cage materials and designs impact ceiling fan ball bearing performance and stability?

1.What is the significance of ceiling fan ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

2.How do different ceiling fan ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove ceiling fan ball bearing: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

3.Do ceiling fan ball bearing come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

4.What are the ceiling fan ball bearing product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

5.What is the role of ceiling fan ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the ceiling fan ball bearing roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.

6.What are the advancements and innovations in ceiling fan ball bearing technology that have emerged in recent years?

Significant advancements have been made in ceiling fan ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

7.What is the production capacity of the factory for ceiling fan ball bearing?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

8.Are there ceramic ceiling fan ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic ceiling fan ball bearing are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

9.How do ceiling fan ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

The type of bearing used also varies between these loads. While deep-groove ceiling fan ball bearing are better equipped to handle radial loads, thrust ball bearings are designed for axial loads. However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.The Bearing Static Capacity, Co, is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race.

10.Are there ongoing research and development efforts aimed at improving ceiling fan ball bearing materials, designs, and lubrication techniques?

A custom ceiling fan ball bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

11.How do cage materials and designs impact ceiling fan ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision ceiling fan ball bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing.

Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.