PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd is one of the leading bearing manufacturers in China. We are a well-known supplier of high-quality carbon brush,ball bearing,commutator,magnet,insulation paper,motor cover and lamination,fan. Our products are widely used in fields such as BLDC motor,compress motor,water pump motor,single and three phase induction motor,washing machine motor,fan motor,air condition motor,servo motor. We are proud to provide customers with the expected product knowledge, applied professional knowledge, quality control, and consistent reliable service.

We have modern computerized machinery and equipment to produce high-precision bearings. Our company is also equipped with complete chemical and metallurgical laboratories as well as standard room facilities.Nide has offices in India, Brazil, Korea, Turkey, and Argentina, good sales and service net work allow us to access and offer service to customers over the world easily and promptly.

| Parameter | Information |

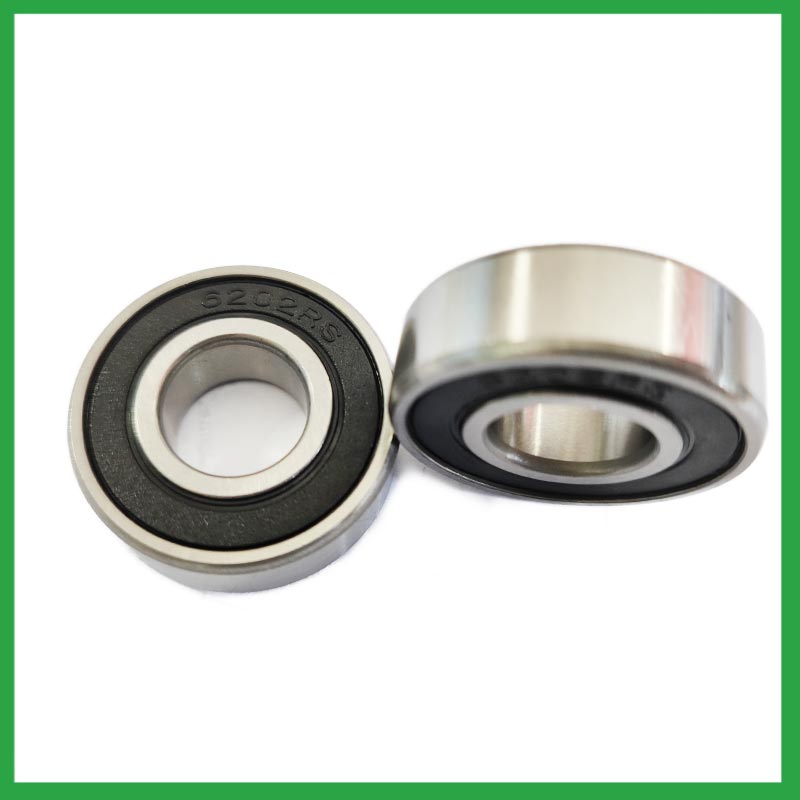

| Product Name | detroit ball bearing |

| Place of Origin | Ningbo,China |

| Brand Name | Nide |

| Material | stainless steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | automotive engines,various industrial equipment, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-insulation paper inserting machine,CE-stator coil winding machine,etc |

| Feature | High precision,Simple structure...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

detroit ball bearing is a component with a ball as the rolling element, consisting of an inner ring, an outer ring, and a ball. They form a closed raceway between the rings, and the ball rolls through a curved surface in the raceway.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

detroit ball bearing---FAQs Guide

2.What are the considerations for choosing between open, shielded, or sealed detroit ball bearing in specific applications?

3.Are there hybrid detroit ball bearing that combine steel rings with ceramic balls to optimize performance in demanding applications?

4.What are the considerations for selecting sealed or shielded detroit ball bearing to protect against contamination and retain lubrication?

5.What are the standard sizes and dimensions of detroit ball bearing?

6.What is the role of detroit ball bearing in reducing friction and energy loss in rotating machinery?

7.How do cage designs affect detroit ball bearing speed and acceleration capabilities in high-speed machinery?

8.What are the common materials used in detroit ball bearing manufacturing?

9.How do different detroit ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

10.About detroit ball bearing,Can I add my own logo?

11.What is the significance of detroit ball bearing lubrication, and how does it affect bearing lifespan and performance?

12.Are there self-aligning detroit ball bearing that accommodate misalignment and shaft deflection in rotating equipment?

1.What maintenance practices are recommended to extend the lifespan of detroit ball bearing and prevent premature failure?

Proper handling and installation of detroit ball bearing is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

2.What are the considerations for choosing between open, shielded, or sealed detroit ball bearing in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded detroit ball bearing can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

3.Are there hybrid detroit ball bearing that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic detroit ball bearing. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

4.What are the considerations for selecting sealed or shielded detroit ball bearing to protect against contamination and retain lubrication?

First, the environment in which your detroit ball bearing operate in can help you identify potential contaminants, allowing you to select your shields or seals accordingly. For example, shielded bearings have a gap that can allow finer contaminants or water from washdown applications to enter the bearing and get into the raceways.The challenge for sealing bearings is to seal the bearing by protecting the bearing from contaminants and running efficiencies.

5.What are the standard sizes and dimensions of detroit ball bearing?

detroit ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

6.What is the role of detroit ball bearing in reducing friction and energy loss in rotating machinery?

detroit ball bearing reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

7.How do cage designs affect detroit ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed detroit ball bearing, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

8.What are the common materials used in detroit ball bearing manufacturing?

Most detroit ball bearing are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

9.How do different detroit ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove detroit ball bearing: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

10.About detroit ball bearing,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

11.What is the significance of detroit ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

12.Are there self-aligning detroit ball bearing that accommodate misalignment and shaft deflection in rotating equipment?

These detroit ball bearing are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.