PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

In years of practice, we have established a strict quality assurance system. Our product range covers fan,carbon brush,thermal protector,ball bearing,magnet,insulation paper, etc. They are widely used in fields such as water pump motor,BLDC motor,washing machine motor,fan motor,servo motor,electric automotive motor,compress motor. We can produce OEM products and make the following drawings. Our principle is to prioritize service and quality!

| Parameter | Information |

|---|---|

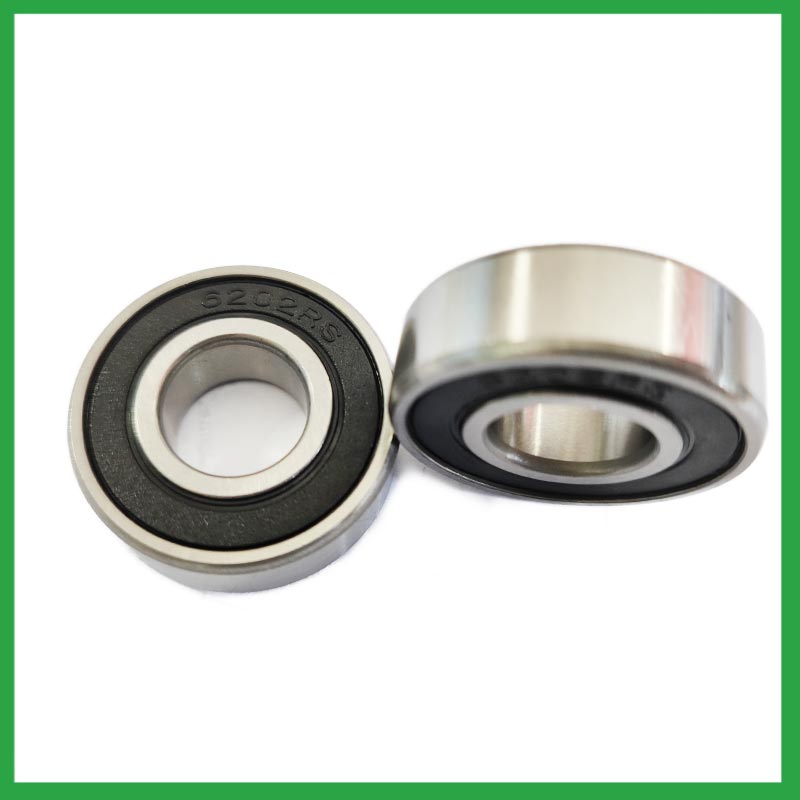

| Product Name | drive shaft ball bearing |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang,China |

| Material | ceramics, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Asia,America,Europe |

| Export Country | India,Brazil,South Korea,Czech Republic,Peru,Saint Pierre and Miquelon,American Samoa,Andorra...etc |

| Application | chemical equipment, etc. |

| OEM/ODM | Acceptatble |

| Size | Customized size |

| Stock | In Stock |

| Feature | Simple structure,Low Noise...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil forming machine,CE-insulation paper inserting machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

drive shaft ball bearing have the advantages of compactness,high efficiency,durability, and high load, and are used in main motion mechanisms and components, such as motors,transmission shafts,tires,resistors, different motion mechanisms and accessories of airplanes and motorcycles.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

drive shaft ball bearing---FAQs Guide

2.How do drive shaft ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

3.Are there specific drive shaft ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

4.What are the advancements and innovations in drive shaft ball bearing technology that have emerged in recent years?

5.Can drive shaft ball bearing be used in both vertical and horizontal orientations?

6.Are there miniature drive shaft ball bearing designed for use in precision instruments and small-scale mechanisms?

7.How do preload adjustments in drive shaft ball bearing affect their performance and suitability for high-precision tasks?

8.Can drive shaft ball bearing handle shock loads and high-impact conditions in heavy machinery?

9.Can drive shaft ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

10.Can drive shaft ball bearing operate in high-speed applications, and what design features make them suitable for such conditions?

1.Are there ceramic drive shaft ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic drive shaft ball bearing are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

2.How do drive shaft ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

3.Are there specific drive shaft ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control drive shaft ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

4.What are the advancements and innovations in drive shaft ball bearing technology that have emerged in recent years?

Significant advancements have been made in drive shaft ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

5.Can drive shaft ball bearing be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations.

Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

6.Are there miniature drive shaft ball bearing designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

7.How do preload adjustments in drive shaft ball bearing affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.

8.Can drive shaft ball bearing handle shock loads and high-impact conditions in heavy machinery?

As a general rule, drive shaft ball bearing are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

9.Can drive shaft ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

10.Can drive shaft ball bearing operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. drive shaft ball bearing are comparatively easy to install and require minimal maintenance.