PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International is one of the leading bearing manufacturers in China. We are a well-known supplier of high-quality magnet,thermal protector,fan,motor cover and lamination,ball bearing,carbon brush. Our products are widely used in fields such as air condition motor,electric bicycle motor,servo motor,electric automotive motor,fan motor,compress motor,washing machine motor. We are proud to provide customers with the expected product knowledge, applied professional knowledge, quality control, and consistent reliable service.

We have modern computerized machinery and equipment to produce high-precision bearings. Our company is also equipped with complete chemical and metallurgical laboratories as well as standard room facilities.Nide has offices in India, Brazil, Korea, Turkey, and Argentina, good sales and service net work allow us to access and offer service to customers over the world easily and promptly.

| Parameter | Information |

|---|---|

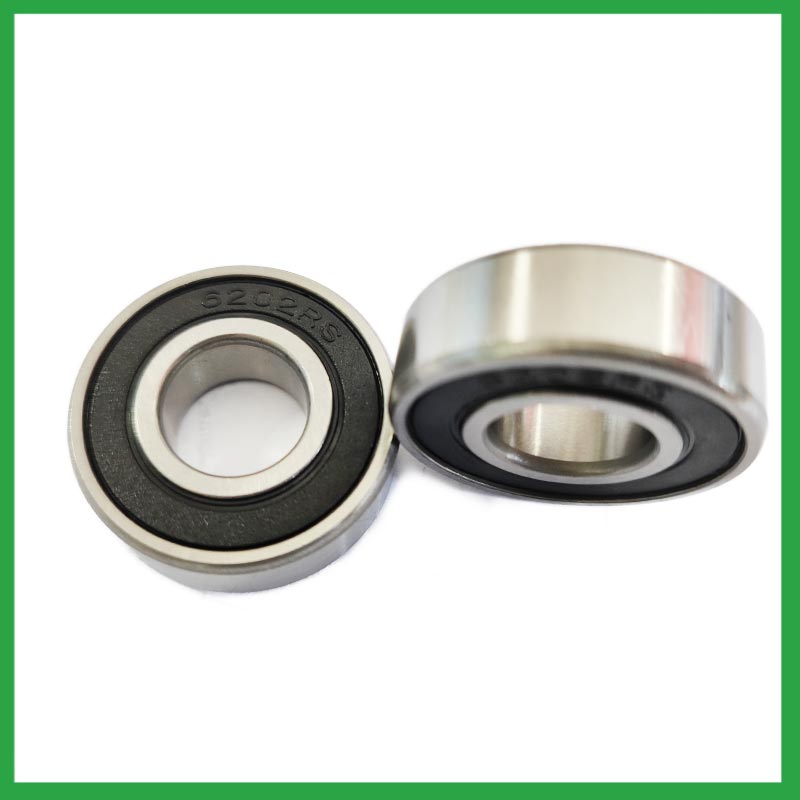

| Product Name | elden ring ball bearing 5 |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang,China |

| Material | chrome steel, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Asia,Europe,Oceania |

| Export Country | India,Brazil,South Korea,Latvia,Bangladesh,Iraq,Germany,Canada...etc |

| Application | food processing machinery,automotive engines, etc. |

| OEM/ODM | Support |

| Size | Customized size |

| Stock | In Stock |

| Feature | Simple structure,Good wear resistance...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding machine,CE-stator coil forming machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

elden ring ball bearing 5 can be used in household appliances, such as refrigerator door leaf wings,barrel machine spindle bearings,vegetable cutters,mixers, etc; It can also be used in industrial fields, such as weighing machines,dishwashers,motors,weaving machine spindle bearings, etc.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

elden ring ball bearing 5---FAQs Guide

2.How do cage designs affect elden ring ball bearing 5 speed and acceleration capabilities in high-speed machinery?

3.What is the significance of elden ring ball bearing 5 lubrication, and how does it affect bearing lifespan and performance?

4.Can elden ring ball bearing 5 be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

5.How do different elden ring ball bearing 5 designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

6.About elden ring ball bearing 5,What about the lead time?

7.What anti-corrosion coatings or treatments are available for elden ring ball bearing 5 used in marine or outdoor applications?

8.Are there specific elden ring ball bearing 5 designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

9.Are there self-aligning elden ring ball bearing 5 that accommodate misalignment and shaft deflection in rotating equipment?

10.How do elden ring ball bearing 5 provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

11.What are the considerations for choosing between open, shielded, or sealed elden ring ball bearing 5 in specific applications?

12.How do preloaded elden ring ball bearing 5 enhance rigidity and reduce clearance in high-precision applications?

13.Can elden ring ball bearing 5 be used in both vertical and horizontal orientations?

14.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

15.About elden ring ball bearing 5,Can I add my own logo?

16.Are there elden ring ball bearing 5 designed for use in critical medical equipment?

1.What are the advancements and innovations in elden ring ball bearing 5 technology that have emerged in recent years?

Significant advancements have been made in elden ring ball bearing 5 steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

2.How do cage designs affect elden ring ball bearing 5 speed and acceleration capabilities in high-speed machinery?

In high-speed elden ring ball bearing 5, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

3.What is the significance of elden ring ball bearing 5 lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

4.Can elden ring ball bearing 5 be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, elden ring ball bearing 5 can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

5.How do different elden ring ball bearing 5 designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove elden ring ball bearing 5: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

6.About elden ring ball bearing 5,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

7.What anti-corrosion coatings or treatments are available for elden ring ball bearing 5 used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether elden ring ball bearing 5 are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

8.Are there specific elden ring ball bearing 5 designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control elden ring ball bearing 5 are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

9.Are there self-aligning elden ring ball bearing 5 that accommodate misalignment and shaft deflection in rotating equipment?

These elden ring ball bearing 5 are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

10.How do elden ring ball bearing 5 provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, elden ring ball bearing 5 operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

11.What are the considerations for choosing between open, shielded, or sealed elden ring ball bearing 5 in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded elden ring ball bearing 5 can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

12.How do preloaded elden ring ball bearing 5 enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

13.Can elden ring ball bearing 5 be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations.

Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

14.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a elden ring ball bearing 5 manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

15.About elden ring ball bearing 5,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

16.Are there elden ring ball bearing 5 designed for use in critical medical equipment?

Precision elden ring ball bearing 5 are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life.

Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.