PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

In years of practice, we have established a strict quality assurance system. Our product range covers magnet,carbon brush,insulation paper,motor cover and lamination,shaft,commutator,fan, etc. They are widely used in fields such as water pump motor,electric automotive motor,BLDC motor,fan motor,air condition motor,washing machine motor,servo motor,electric bicycle motor. We can produce OEM products and make the following drawings. Our principle is to prioritize service and quality!

| Parameter | Information |

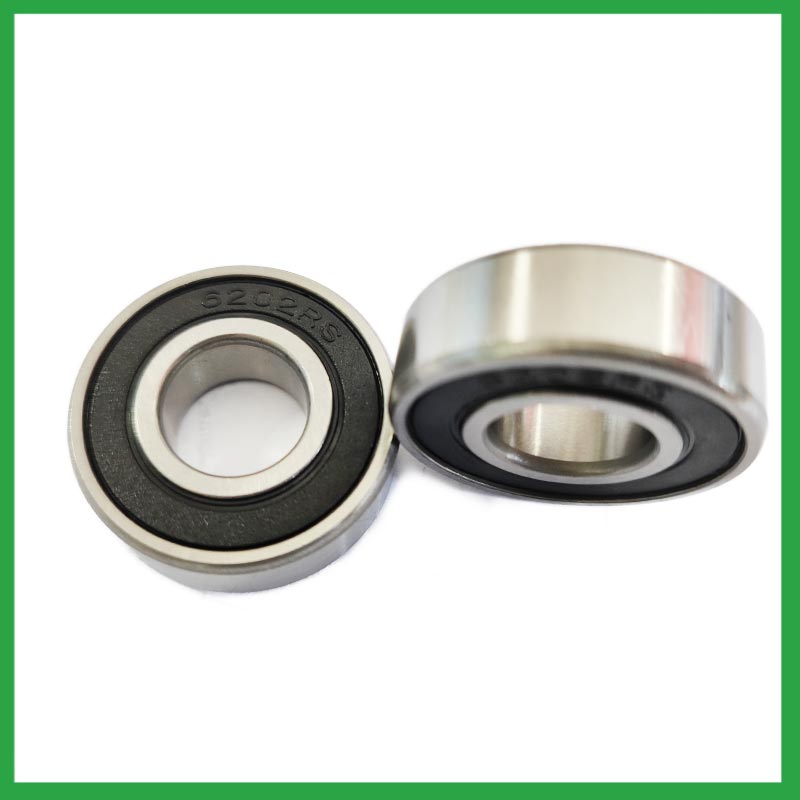

| Product Name | havells double ball bearing fan |

| Place of Origin | Ningbo,Zhejiang,China |

| Brand Name | Nide |

| Material | chrome steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | textile machinery, etc. |

| Size(mm) | customize |

| Color | white+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil winding inserting machine,CE-stator coil winding machine,etc |

| Feature | High speed,Simple structure...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

havells double ball bearing fan have the advantages of compactness,low friction coefficient,high efficiency, and high load, and are used in main motion mechanisms and components, such as tires,automotive drive components,motors,transmission shafts, different motion mechanisms and accessories of airplanes and motorcycles.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

havells double ball bearing fan---FAQs Guide

2.About havells double ball bearing fan,Will you check the products before shipment?

3.Are there hybrid havells double ball bearing fan that combine steel rings with ceramic balls to optimize performance in demanding applications?

4.What are the considerations for choosing between open, shielded, or sealed havells double ball bearing fan in specific applications?

5.How do preloaded havells double ball bearing fan enhance rigidity and reduce clearance in high-precision applications?

6.What are the common materials used in havells double ball bearing fan manufacturing?

7.What anti-corrosion coatings or treatments are available for havells double ball bearing fan used in marine or outdoor applications?

8.As a havells double ball bearing fan manufacturer,How Can We Guarantee Quality?

9.What is the role of havells double ball bearing fan in reducing friction and energy loss in rotating machinery?

10.Can havells double ball bearing fan operate in high-speed applications, and what design features make them suitable for such conditions?

11.About havells double ball bearing fan,What about the lead time?

12.What is the typical noise level associated with havells double ball bearing fan, and how are noise-reduction techniques applied?

13.Can havells double ball bearing fan be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

1.Can havells double ball bearing fan handle shock loads and high-impact conditions in heavy machinery?

As a general rule, havells double ball bearing fan are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

2.About havells double ball bearing fan,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

3.Are there hybrid havells double ball bearing fan that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic havells double ball bearing fan. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

4.What are the considerations for choosing between open, shielded, or sealed havells double ball bearing fan in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded havells double ball bearing fan can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

5.How do preloaded havells double ball bearing fan enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

6.What are the common materials used in havells double ball bearing fan manufacturing?

Most havells double ball bearing fan are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

7.What anti-corrosion coatings or treatments are available for havells double ball bearing fan used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether havells double ball bearing fan are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

8.As a havells double ball bearing fan manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

9.What is the role of havells double ball bearing fan in reducing friction and energy loss in rotating machinery?

havells double ball bearing fan reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

10.Can havells double ball bearing fan operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. havells double ball bearing fan are comparatively easy to install and require minimal maintenance.

11.About havells double ball bearing fan,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

12.What is the typical noise level associated with havells double ball bearing fan, and how are noise-reduction techniques applied?

To measure in accurate way the havells double ball bearing fan noise under rotation during their manufacturing process is a key activity particularly in the production of medium, small and ultra-small deep groove ball bearings. This capability in bearings noise analysis has become the real distinguishing element between a standard bearings noise equipment and a superior class one.

The various types of vibration and sound in rolling bearings can be grouped in four main categories: structural, manufacturing, handling and other. The structural vibration consists mostly of race, click, squeal and cage noise: it can be continuous or intermittent depending on specific cases. The manufacturing vibration is instead related to the waviness noise generated by the geometrical imperfections of inner and outer ring and of rolling elements, being always continuous in nature. The so-called handling vibration is normally associated with flaw and contamination and is generating – in most of the cases – irregular noise. Then there are other types of vibrabition that include noise generated by sealing and lubricant (irregular) or by runout (continuous).

13.Can havells double ball bearing fan be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, havells double ball bearing fan can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.