PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is located in the beautiful sea shore city--Ningbo, taking the advantage of advanced industries hub, perfect supply chain and convenient transportation, and integrating professional team with rich motor manufacturing experience , we focus on supplying the Motor Components One Stop Sourcing Platform to our customers.

Our products include carbon brush,commutator,magnet,thermal protector,shaft,insulation paper,etc.Apart from these products, we also provide the service for the motor manufacturing technical consultant, project support and turn-key project.

| Parameter | Information |

|---|---|

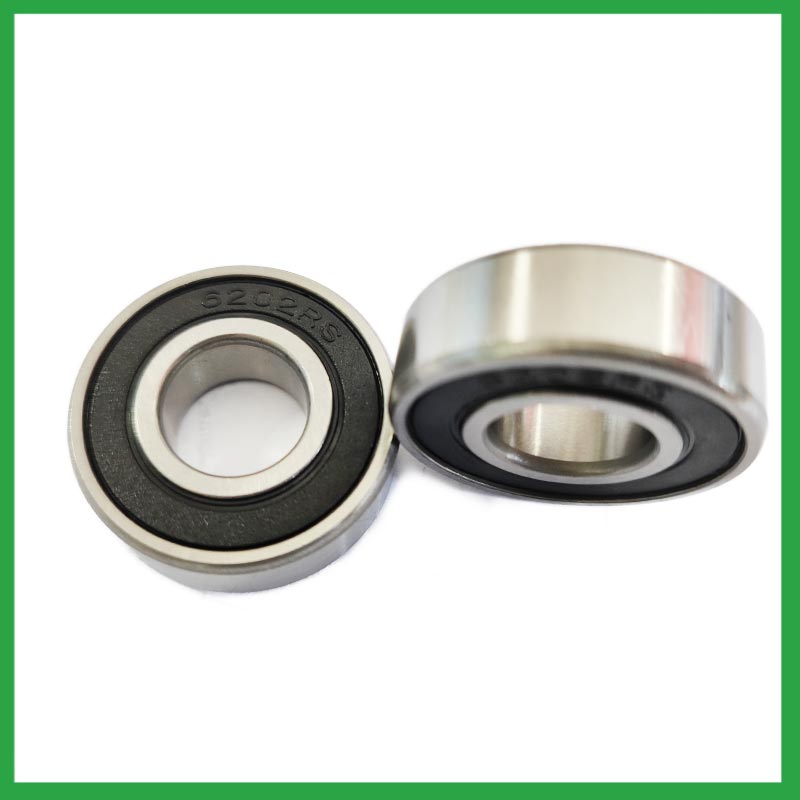

| Product Name | koyo ball bearing |

| Brand Name | NIDE |

| Place of Origin | Ningbo,Zhejiang,China |

| Material | stainless steel, etc. |

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Africa,Europe,Oceania |

| Export Country | India,Brazil,South Korea,Glorioso Islands,French Polynesia,Congo, Republic of the,Nicaragua,Guernsey...etc |

| Application | automotive engines,fan electric motor, etc. |

| OEM/ODM | Acceptatble |

| Size | Customized size |

| Stock | In Stock |

| Feature | High speed,Low Noise...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding inserting machine,CE-stator coil forming machine,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

koyo ball bearing is a component with a ball as the rolling element, consisting of an inner ring, an outer ring, and a ball. They form a closed raceway between the rings, and the ball rolls through a curved surface in the raceway.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

koyo ball bearing---FAQs Guide

2.About koyo ball bearing,What about the lead time?

3.Can koyo ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

4.How do koyo ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

5.What are the after-sales services available for koyo ball bearing?

6.What is the role of koyo ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

7.What are the considerations for choosing between open, shielded, or sealed koyo ball bearing in specific applications?

8.How do different koyo ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

9.Are there ongoing research and development efforts aimed at improving koyo ball bearing materials, designs, and lubrication techniques?

10.What are the advancements and innovations in koyo ball bearing technology that have emerged in recent years?

11.What are the common materials used in koyo ball bearing manufacturing?

12.What is the role of koyo ball bearing in reducing friction and energy loss in rotating machinery?

13.Are there ceramic koyo ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

14.How do koyo ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

1.As a koyo ball bearing manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

2.About koyo ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

3.Can koyo ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

koyo ball bearing are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

4.How do koyo ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

5.What are the after-sales services available for koyo ball bearing?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

6.What is the role of koyo ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the koyo ball bearing roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.

7.What are the considerations for choosing between open, shielded, or sealed koyo ball bearing in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded koyo ball bearing can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

8.How do different koyo ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove koyo ball bearing: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

9.Are there ongoing research and development efforts aimed at improving koyo ball bearing materials, designs, and lubrication techniques?

A custom koyo ball bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

10.What are the advancements and innovations in koyo ball bearing technology that have emerged in recent years?

Significant advancements have been made in koyo ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

11.What are the common materials used in koyo ball bearing manufacturing?

Most koyo ball bearing are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

12.What is the role of koyo ball bearing in reducing friction and energy loss in rotating machinery?

koyo ball bearing reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

13.Are there ceramic koyo ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic koyo ball bearing are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

14.How do koyo ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

The type of bearing used also varies between these loads. While deep-groove koyo ball bearing are better equipped to handle radial loads, thrust ball bearings are designed for axial loads. However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.The Bearing Static Capacity, Co, is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race.