PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd was established in 2010. We produce shaft,ball bearing,fan,thermal protector,motor cover and lamination,commutator and other products. Our unwavering commitment to quality has been recognized by the National Testing Center and the Zhejiang Provincial Testing Center. We adhere to ISO 9001:2015 and CE statior standards, prioritize quality, and operate with integrity.

We prioritize quality and first-class service, constantly pursuing perfection. We have a deep understanding of the precise needs of our customers, and our important motor component manufacturing network and strict quality control system enable us to provide high-quality products to customers at reasonable prices.

| Parameter | Information |

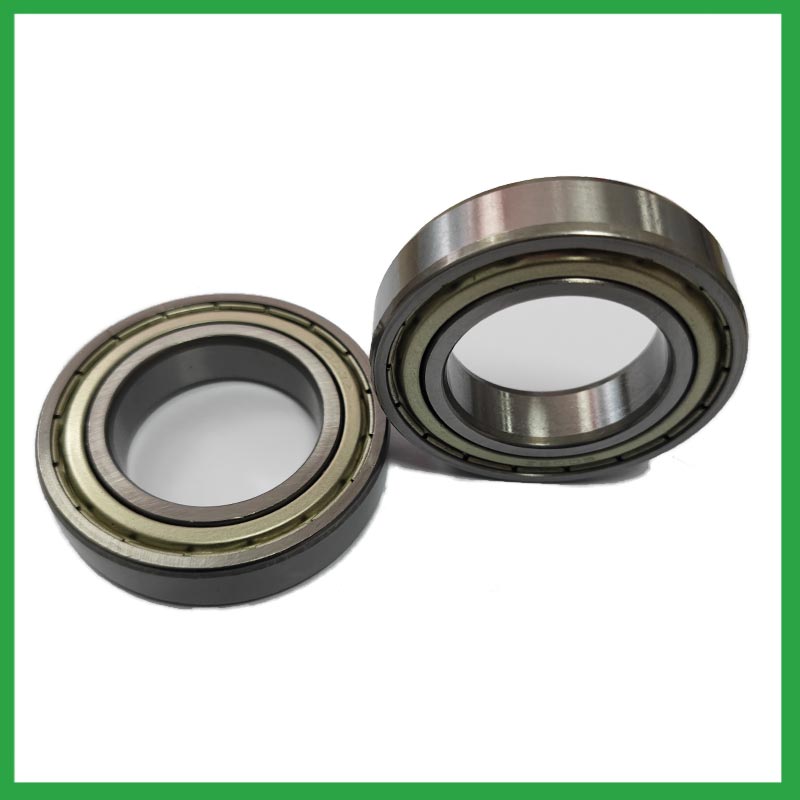

| Product Name | miniature angular contact ball bearing |

| Brand Name | Nide |

| Place of Origin | Ningbo,Zhejiang,China |

| Type | Ball |

| Material | stainless steel, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | high-speed electric tools, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Sri Lanka,American Samoa,Iraq,Ethiopia,Bermuda...etc |

| Export region | America,Oceania,Asia... |

| Certification | ISO 9001 Certification,CE-stator coil winding inserting machine,CE-insulation paper inserting machine,etc |

| Precision Rating | as per customer's requirement |

| Feature | High precision,Good wear resistance...etc |

| Packaging Details | Suitable for sea transportation |

| Color | gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of miniature angular contact ball bearing is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

miniature angular contact ball bearing---FAQs Guide

2.About miniature angular contact ball bearing,Will you check the products before shipment?

3.What is the significance of miniature angular contact ball bearing lubrication, and how does it affect bearing lifespan and performance?

4.What are the advancements and innovations in miniature angular contact ball bearing technology that have emerged in recent years?

5.What are the considerations for selecting sealed or shielded miniature angular contact ball bearing to protect against contamination and retain lubrication?

6.About miniature angular contact ball bearing,What about the lead time?

7.Are there miniature miniature angular contact ball bearing designed for use in precision instruments and small-scale mechanisms?

8.Do miniature angular contact ball bearing come in various tolerance classes?

9.Are there miniature angular contact ball bearing designed for extreme temperature environments, such as cryogenic or furnace applications?

10.Can miniature angular contact ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

11.What is the production capacity of the factory for miniature angular contact ball bearing?

12.How do miniature angular contact ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

13.Are there specific miniature angular contact ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

14.As a miniature angular contact ball bearing manufacturer,What is your payment method?

15.How do miniature angular contact ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

16.How do sealed miniature angular contact ball bearing prevent the ingress of contaminants and extend the bearing's service life?

1.Can miniature angular contact ball bearing handle shock loads and high-impact conditions in heavy machinery?

As a general rule, miniature angular contact ball bearing are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

2.About miniature angular contact ball bearing,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

3.What is the significance of miniature angular contact ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

4.What are the advancements and innovations in miniature angular contact ball bearing technology that have emerged in recent years?

Significant advancements have been made in miniature angular contact ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

5.What are the considerations for selecting sealed or shielded miniature angular contact ball bearing to protect against contamination and retain lubrication?

First, the environment in which your miniature angular contact ball bearing operate in can help you identify potential contaminants, allowing you to select your shields or seals accordingly. For example, shielded bearings have a gap that can allow finer contaminants or water from washdown applications to enter the bearing and get into the raceways.The challenge for sealing bearings is to seal the bearing by protecting the bearing from contaminants and running efficiencies.

6.About miniature angular contact ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

7.Are there miniature miniature angular contact ball bearing designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

8.Do miniature angular contact ball bearing come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

9.Are there miniature angular contact ball bearing designed for extreme temperature environments, such as cryogenic or furnace applications?

High temperature miniature angular contact ball bearing use specialized lubricants to stand up to high temperatures. Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

10.Can miniature angular contact ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

11.What is the production capacity of the factory for miniature angular contact ball bearing?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

12.How do miniature angular contact ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

The type of bearing used also varies between these loads. While deep-groove miniature angular contact ball bearing are better equipped to handle radial loads, thrust ball bearings are designed for axial loads. However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.The Bearing Static Capacity, Co, is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race.

13.Are there specific miniature angular contact ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control miniature angular contact ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

14.As a miniature angular contact ball bearing manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

15.How do miniature angular contact ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, miniature angular contact ball bearing operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

16.How do sealed miniature angular contact ball bearing prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the miniature angular contact ball bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.