PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is a professional bearing manufacturer and distributor. We were founded in 2010 and have been engaged in the bearing industry for 13 years. Our company specializes in producing motor cover and lamination,commutator,shaft,carbon brush,thermal protector,insulation paper and other products. Meanwhile, we have a good cooperative relationship with world-renowned bearing manufacturers. Relying on the first-class bearing quality to ensure that we have many customers around the world, such as the United States, Europe, Africa, and India, Brazil, Türkiye, Western Sahara,Bolivia,India,Turkey and other countries.

Nide team could manufacture ball bearing as per customer’s drawing and samples. If customer only has samples, we could also design drawing for our customer. We also provide customized service.Our goal is to help customers reduce tedious purchasing pressures while obtaining high-quality products. Nide hopes to provide one-stop motor manufacturing services to global customers.

| Parameter | Information |

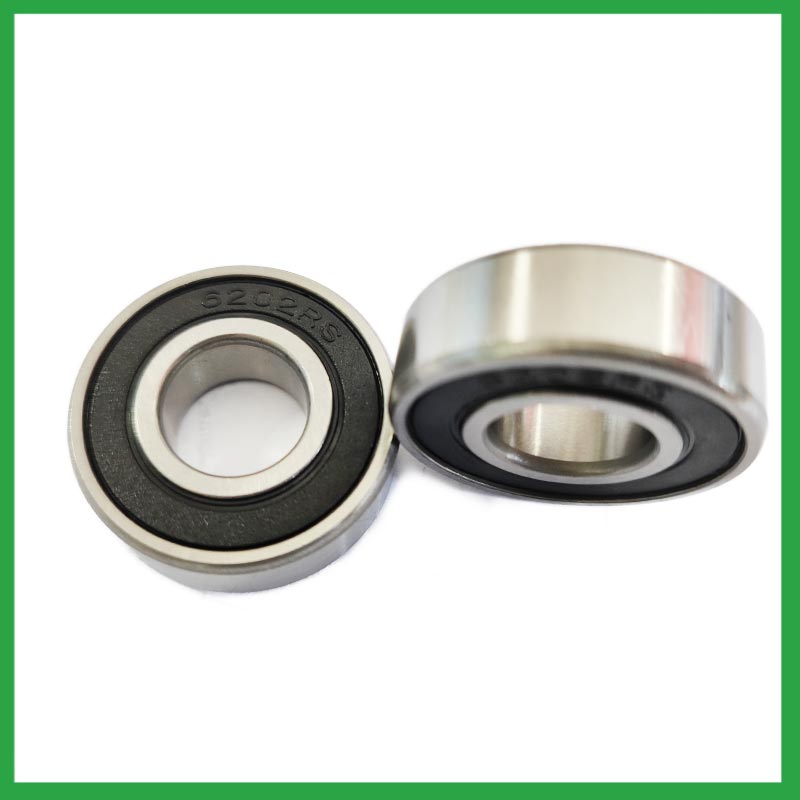

| Product Name | precision ball bearing |

| Place of Origin | China |

| Brand Name | Nide |

| Material | stainless steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | chemical equipment,small rotary motors, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,ISO9001:2015 certificate,CE-stator coil lacing machine,etc |

| Feature | Strong carrying capacity,Simple structure...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

precision ball bearing have the advantages of durability,low friction coefficient,compactness,lightweight, and high load, and are used in main motion mechanisms and components, such as transmission shafts,resistors,automotive drive components, different motion mechanisms and accessories of airplanes and motorcycles.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

precision ball bearing---FAQs Guide

2.How do preload adjustments in precision ball bearing affect their performance and suitability for high-precision tasks?

3.What is the significance of precision ball bearing lubrication, and how does it affect bearing lifespan and performance?

4.As a precision ball bearing manufacturer,How Can We Guarantee Quality?

5.How do precision ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

6.Where can precision ball bearing be used?

7.How do cage designs affect precision ball bearing speed and acceleration capabilities in high-speed machinery?

8.About precision ball bearing,What about the lead time?

9.How do sealed precision ball bearing prevent the ingress of contaminants and extend the bearing's service life?

10.As a precision ball bearing manufacturer,can you supply samples?

11.Are there specific precision ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

1.What are the common materials used in precision ball bearing manufacturing?

Most precision ball bearing are made of a type of steel known as high carbon chromium steel, often called chrome steel. This is used for reasons of cost and durability. Bearings are also made from other materials such as stainless steel, ceramics and plastic.

2.How do preload adjustments in precision ball bearing affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.

3.What is the significance of precision ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

4.As a precision ball bearing manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

5.How do precision ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

6.Where can precision ball bearing be used?

precision ball bearing are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

7.How do cage designs affect precision ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed precision ball bearing, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

8.About precision ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

9.How do sealed precision ball bearing prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the precision ball bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

10.As a precision ball bearing manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

11.Are there specific precision ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control precision ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.