PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd was established in 2010. We produce ball bearing,magnet,motor cover and lamination,commutator,shaft,insulation paper,thermal protector and other products. Our unwavering commitment to quality has been recognized by the National Testing Center and the Zhejiang Provincial Testing Center. We adhere to ISO 9001:2015 and CE statior standards, prioritize quality, and operate with integrity.

We prioritize quality and first-class service, constantly pursuing perfection. We have a deep understanding of the precise needs of our customers, and our important motor component manufacturing network and strict quality control system enable us to provide high-quality products to customers at reasonable prices.

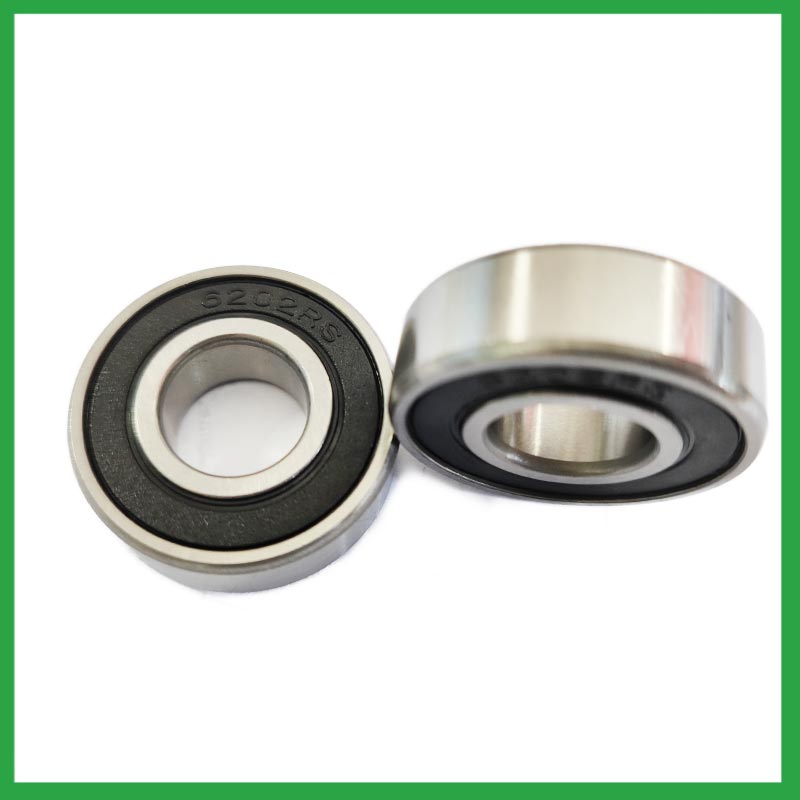

| Parameter | Information |

| Product Name | r12zz ball bearing |

| Place of Origin | Ningbo,Zhejiang |

| Brand Name | Nide |

| Material | ceramics, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | high-speed electric tools,machine tools, etc. |

| Size(mm) | customize |

| Color | Silver gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil winding inserting machine,CE-stator coil lacing machine,etc |

| Feature | Good wear resistance,Strong carrying capacity...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

r12zz ball bearing have the advantages of low friction coefficient,high efficiency,durability, and high load, and are used in main motion mechanisms and components, such as motors,automotive drive components,resistors,tires, different motion mechanisms and accessories of airplanes and motorcycles.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

r12zz ball bearing---FAQs Guide

2.As a r12zz ball bearing manufacturer,Your product certifications?

3.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

4.What is the role of r12zz ball bearing in reducing friction and energy loss in rotating machinery?

5.How do r12zz ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

6.Are there r12zz ball bearing designed for extreme temperature environments, such as cryogenic or furnace applications?

7.What are the r12zz ball bearing product skill training options?

8.What are the advancements and innovations in r12zz ball bearing technology that have emerged in recent years?

9.What are the standard sizes and dimensions of r12zz ball bearing?

10.What is the load distribution within a r12zz ball bearing, and how does it vary between different bearing configurations?

1.Are there miniature r12zz ball bearing designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

2.As a r12zz ball bearing manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

3.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a r12zz ball bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

4.What is the role of r12zz ball bearing in reducing friction and energy loss in rotating machinery?

r12zz ball bearing reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

5.How do r12zz ball bearing contribute to the overall efficiency and energy savings in industrial machinery and transportation systems?

The balls roll along the raceway, allowing for smooth rotation of the machinery or equipment. Ball bearings are used to support rotating, reduce friction and support radial and axial loads in high-load, high-speed applications where reliability and efficiency are critical.

6.Are there r12zz ball bearing designed for extreme temperature environments, such as cryogenic or furnace applications?

High temperature r12zz ball bearing use specialized lubricants to stand up to high temperatures. Grease-packed bearings are pre-filled with fluorine grease for high temperatures, while YS and SJ bearings use molybdenum disulfide (MoS2) solid lubricant to withstand temperatures up to 350°C and 400°C respectively.

7.What are the r12zz ball bearing product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

8.What are the advancements and innovations in r12zz ball bearing technology that have emerged in recent years?

Significant advancements have been made in r12zz ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

9.What are the standard sizes and dimensions of r12zz ball bearing?

r12zz ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

10.What is the load distribution within a r12zz ball bearing, and how does it vary between different bearing configurations?

The load distribution between the rolling elements and raceway is crucial in performance evaluation of rolling element bearings. Determine the load distribution by measuring the strain response at the bearing surface with a notched housing. Finite element analysis shows that the introduction of notches does not affect the load distribution. An experimental system was developed to investigate the load distribution in a cylindrical roller bearing. The experimental static load distribution agrees well with the theoretical calculation. The dynamic load at specific position of load zone reflects the manufacture difference among rollers and dynamic balance of distributing loads.