PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International Co., Ltd is located in the beautiful sea shore city--Ningbo, taking the advantage of advanced industries hub, perfect supply chain and convenient transportation, and integrating professional team with rich motor manufacturing experience , we focus on supplying the Motor Components One Stop Sourcing Platform to our customers.

Our products include insulation paper,carbon brush,motor cover and lamination,ball bearing,commutator,magnet,shaft,etc.Apart from these products, we also provide the service for the motor manufacturing technical consultant, project support and turn-key project.

| Parameter | Information |

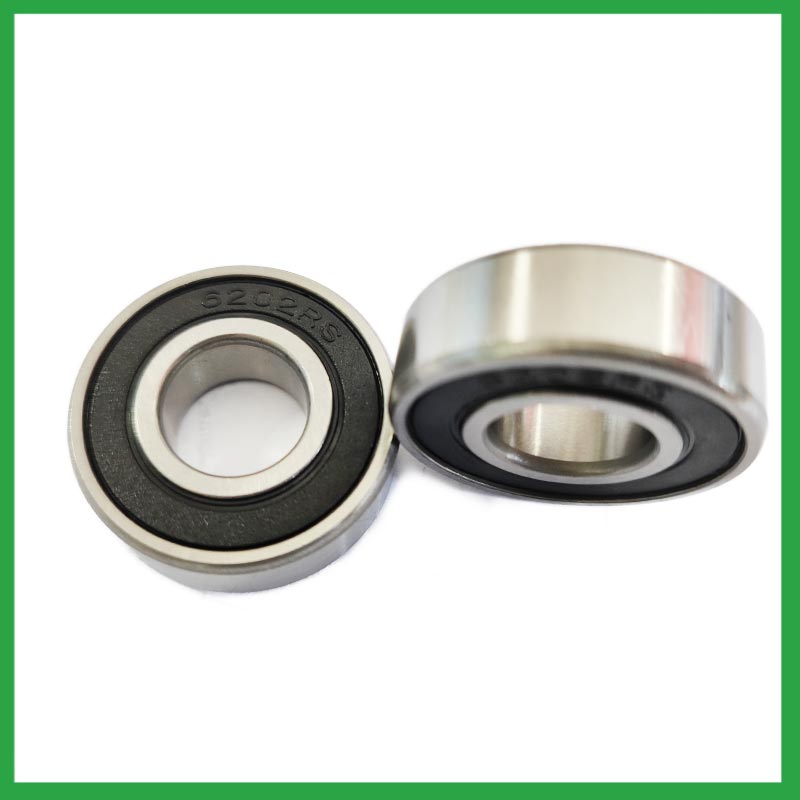

| Product Name | sealed ball bearing |

| Place of Origin | Ningbo,Zhejiang |

| Brand Name | Nide |

| Material | stainless steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | small rotary motors, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil winding machine,ISO9001:2015 certificate,etc |

| Feature | Simple structure,High speed...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

sealed ball bearing is a component with a ball as the rolling element, consisting of an inner ring, an outer ring, and a ball. They form a closed raceway between the rings, and the ball rolls through a curved surface in the raceway.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

sealed ball bearing---FAQs Guide

2.How do preloaded sealed ball bearing enhance rigidity and reduce clearance in high-precision applications?

3.About sealed ball bearing,Can I add my own logo?

4.About sealed ball bearing,Will you check the products before shipment?

5.How do preload adjustments in sealed ball bearing affect their performance and suitability for high-precision tasks?

6.As a sealed ball bearing manufacturer,can you supply samples?

7.What anti-corrosion coatings or treatments are available for sealed ball bearing used in marine or outdoor applications?

8.What are the advancements and innovations in sealed ball bearing technology that have emerged in recent years?

9.Can sealed ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

10.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

11.Are there hybrid sealed ball bearing that combine steel rings with ceramic balls to optimize performance in demanding applications?

12.Do sealed ball bearing come in various tolerance classes?

13.Can sealed ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

1.What is the role of sealed ball bearing in reducing friction and energy loss in rotating machinery?

sealed ball bearing reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

2.How do preloaded sealed ball bearing enhance rigidity and reduce clearance in high-precision applications?

Enhance Rigidity: By applying a controlled axial force, preload increases the bearing's resistance to external forces and moments. This heightened rigidity is essential in applications where any deflection or misalignment must be minimized, such as in machine tools or robotic systems.

3.About sealed ball bearing,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

4.About sealed ball bearing,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

5.How do preload adjustments in sealed ball bearing affect their performance and suitability for high-precision tasks?

Benefits of Preloading a Bearing

Optimizes the ball spin to roll ratio.

Increases the rigidity of an application.

Protects from excessive ball skidding.

Decreases application vibration and sliding friction.

High running accuracy (even if load conditions keep changing)

Increases bearing load capacity.

6.As a sealed ball bearing manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

7.What anti-corrosion coatings or treatments are available for sealed ball bearing used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether sealed ball bearing are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

8.What are the advancements and innovations in sealed ball bearing technology that have emerged in recent years?

Significant advancements have been made in sealed ball bearing steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

9.Can sealed ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, sealed ball bearing can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

10.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a sealed ball bearing manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

11.Are there hybrid sealed ball bearing that combine steel rings with ceramic balls to optimize performance in demanding applications?

Hybrid Ceramic sealed ball bearing. Ceramic ball bearings (also known as hybrid bearings) are the one component that'll easily optimize the performance of your application. Hybrid bearings have ceramic (silicon nitride, Si3N4) balls and 52100 bearing steel rings.

12.Do sealed ball bearing come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

13.Can sealed ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.