PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd was founded in 2010 and is located in the high-tech zone of Ningbo, the industrial center of China. It is very close to Ningbo Port and Shanghai Port. We products products including motor cover and lamination,insulation paper,carbon brush,ball bearing,thermal protector,fan,shaft, etc The product is widely used in industries such as washing machine motor,BLDC motor,servo motor,electric automotive motor,compress motor,electric bicycle motor,single and three phase induction motor,fan motor.

In addition to building machines internally and controlling their quality and service system, we also provide customers with some auxiliary machines outsourced from other professional manufacturers. Its purpose is to reduce additional work for customers and alleviate concerns about quality issues. With excellent service, unique philosophy, professional team, and reliable quality, we have gradually won the trust of global customers.

| Parameter | Information |

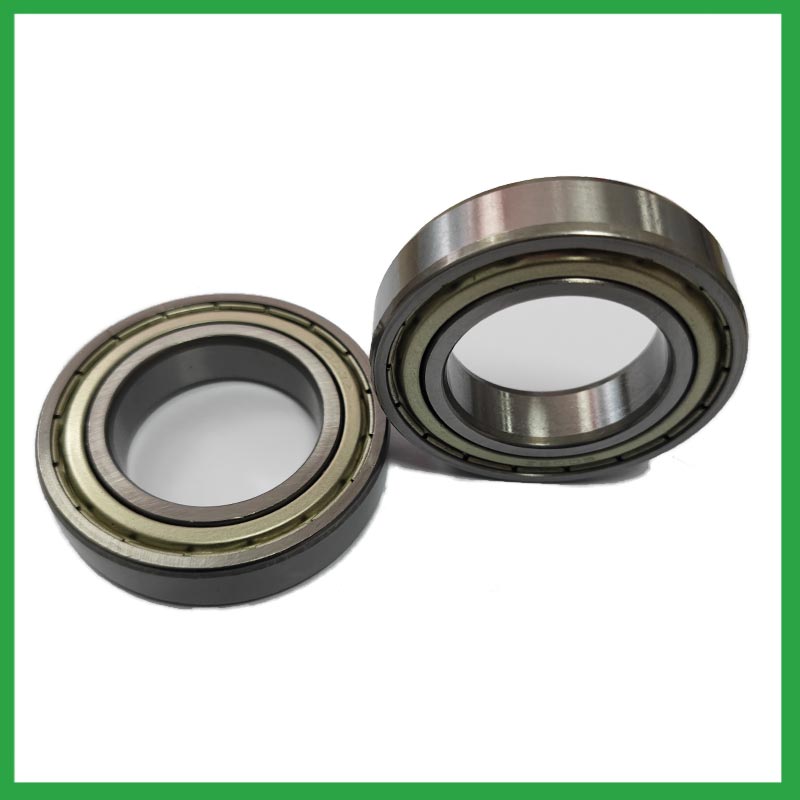

| Product Name | square ball bearing |

| Brand Name | Nide |

| Place of Origin | China |

| Type | Ball |

| Material | chrome steel, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | small rotary motors,chemical equipment, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,India,Estonia,Slovakia,Northern Mariana Islands...etc |

| Export region | Oceania,Africa,America... |

| Certification | ISO 9001 Certification,CE-stator coil winding inserting machine,CE-insulation paper inserting machine,etc |

| Precision Rating | as per customer's requirement |

| Feature | Good wear resistance,High precision...etc |

| Packaging Details | Suitable for sea transportation |

| Color | white+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

Bearings with ball bearings as rolling elements mainly include thrust ball bearings,adjustable ball bearings,cylindrical roller bearings,self-aligning ball bearings, etc.

Before use, the model, size, and design of the ball bearing should be confirmed to ensure suitable application;

During installation, the installation load of the ball bearing should be minimized as much as possible to avoid unnecessary damage;

The bearing shaft and the bearing frame should be stable at the same time to avoid excessive tension.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

square ball bearing---FAQs Guide

2.As a square ball bearing manufacturer,Your product certifications?

3.Can square ball bearing operate in high-speed applications, and what design features make them suitable for such conditions?

4.Are there specific square ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

5.What is the load distribution within a square ball bearing, and how does it vary between different bearing configurations?

6.How do square ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

7.Can square ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

8.About square ball bearing,What about the lead time?

9.Can square ball bearing be used in both vertical and horizontal orientations?

10.How do square ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

11.What is the role of square ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

12.Are there ongoing research and development efforts aimed at improving square ball bearing materials, designs, and lubrication techniques?

13.What maintenance practices are recommended to extend the lifespan of square ball bearing and prevent premature failure?

1.How do sealed square ball bearing prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the square ball bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

2.As a square ball bearing manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

3.Can square ball bearing operate in high-speed applications, and what design features make them suitable for such conditions?

They have very low rolling friction and are optimized for low noise and low vibration. This makes them ideal for high-speed applications. square ball bearing are comparatively easy to install and require minimal maintenance.

4.Are there specific square ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control square ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

5.What is the load distribution within a square ball bearing, and how does it vary between different bearing configurations?

The load distribution between the rolling elements and raceway is crucial in performance evaluation of rolling element bearings. Determine the load distribution by measuring the strain response at the bearing surface with a notched housing. Finite element analysis shows that the introduction of notches does not affect the load distribution. An experimental system was developed to investigate the load distribution in a cylindrical roller bearing. The experimental static load distribution agrees well with the theoretical calculation. The dynamic load at specific position of load zone reflects the manufacture difference among rollers and dynamic balance of distributing loads.

6.How do square ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, square ball bearing operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

7.Can square ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

square ball bearing are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

8.About square ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

9.Can square ball bearing be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations.

Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.

10.How do square ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

The type of bearing used also varies between these loads. While deep-groove square ball bearing are better equipped to handle radial loads, thrust ball bearings are designed for axial loads. However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.The Bearing Static Capacity, Co, is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race.

11.What is the role of square ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the square ball bearing roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.

12.Are there ongoing research and development efforts aimed at improving square ball bearing materials, designs, and lubrication techniques?

A custom square ball bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

13.What maintenance practices are recommended to extend the lifespan of square ball bearing and prevent premature failure?

Proper handling and installation of square ball bearing is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.