PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

In years of practice, we have established a strict quality assurance system. Our product range covers thermal protector,shaft,motor cover and lamination,carbon brush,magnet,insulation paper, etc. They are widely used in fields such as servo motor,air condition motor,electric bicycle motor,fan motor,electric automotive motor,BLDC motor,single and three phase induction motor,compress motor. We can produce OEM products and make the following drawings. Our principle is to prioritize service and quality!

| Parameter | Information |

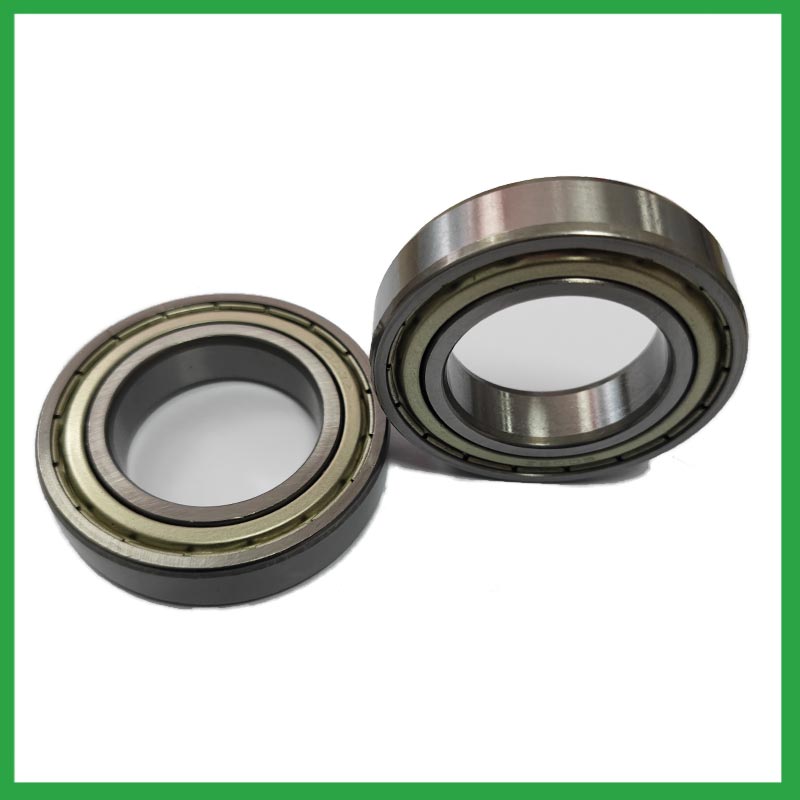

| Product Name | swivel ball bearing |

| Place of Origin | Ningbo,China |

| Brand Name | Nide |

| Material | stainless steel, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | aviation engines, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-stator coil lacing machine,CE-stator coil winding machine,etc |

| Feature | Strong carrying capacity,High speed...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

swivel ball bearing require thrust for installation, which can be achieved by using a combination ring made of steel sleeve and transmission rubber, or by using an adjustment plate to tighten the bolt to form a combination ring installation structure.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

swivel ball bearing---FAQs Guide

2.Are there ongoing research and development efforts aimed at improving swivel ball bearing materials, designs, and lubrication techniques?

3.What is a ball bearing?

4.As a swivel ball bearing manufacturer,How Can We Guarantee Quality?

5.How do swivel ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

6.As a swivel ball bearing manufacturer,What is your payment method?

7.About swivel ball bearing,Can I add my own logo?

8.About swivel ball bearing,What about the lead time?

9.How do cage designs affect swivel ball bearing speed and acceleration capabilities in high-speed machinery?

10.What are the considerations for choosing between open, shielded, or sealed swivel ball bearing in specific applications?

11.Are there specific swivel ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

12.What anti-corrosion coatings or treatments are available for swivel ball bearing used in marine or outdoor applications?

13.What is the role of swivel ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

1.Are there miniature swivel ball bearing designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

2.Are there ongoing research and development efforts aimed at improving swivel ball bearing materials, designs, and lubrication techniques?

A custom swivel ball bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

3.What is a ball bearing?

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

4.As a swivel ball bearing manufacturer,How Can We Guarantee Quality?

Always a Pre-production Sample Before Mass Production;Always Final Inspection Before Shipment.

5.How do swivel ball bearing provide smooth and controlled motion in various mechanical systems, such as conveyor belts or automobiles?

In essence, swivel ball bearing operate on the principle that it's far more efficient to roll over surfaces than to slide, thereby significantly reducing friction and facilitating smooth movement of machinery parts.

6.As a swivel ball bearing manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

7.About swivel ball bearing,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

8.About swivel ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

9.How do cage designs affect swivel ball bearing speed and acceleration capabilities in high-speed machinery?

In high-speed swivel ball bearing, external load has a great effect on cage stability and sliding ratio, especially for the bearings at work in the starting process. The cage stability is worse in the beginning of the bearing starting process. The axial load greatly influences cage dynamic performance in the bearing starting process.

In addition, while ball bearings worked under steady conditions, axial load and radial load both have a great influence on cage dynamic performance. The effects of axial load on cage dynamic performance during the bearing starting process are opposite from the effects under steady conditions.

10.What are the considerations for choosing between open, shielded, or sealed swivel ball bearing in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded swivel ball bearing can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

11.Are there specific swivel ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control swivel ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

12.What anti-corrosion coatings or treatments are available for swivel ball bearing used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether swivel ball bearing are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).

13.What is the role of swivel ball bearing in reducing friction and wear in automotive applications, such as wheel hubs and transmissions?

When a load is applied to a ball bearing, the swivel ball bearing roll freely between the inner and outer rings. This rolling action significantly reduces friction compared to sliding contact, resulting in smoother rotation and reduced wear.