PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-HXQ-1010

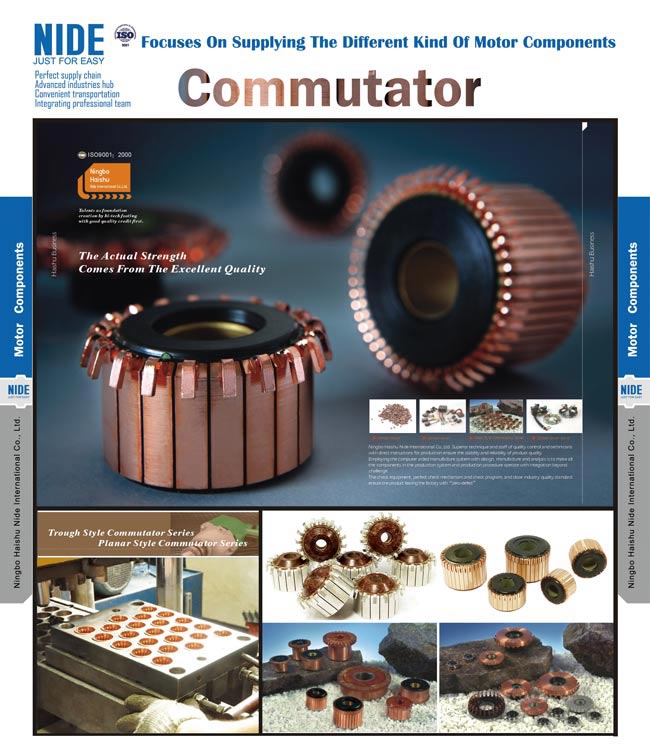

The Electric Motor Commutator is suitable for Alternator, AC Motor, Generators and DC motors.NIDE supplies 1200 different types of motor commutators to provide customers with a full range of motor accessories solutions. Commutator can be customized according to customer requirements, support ODM,OEM, etc.

Categoryes: Commutator

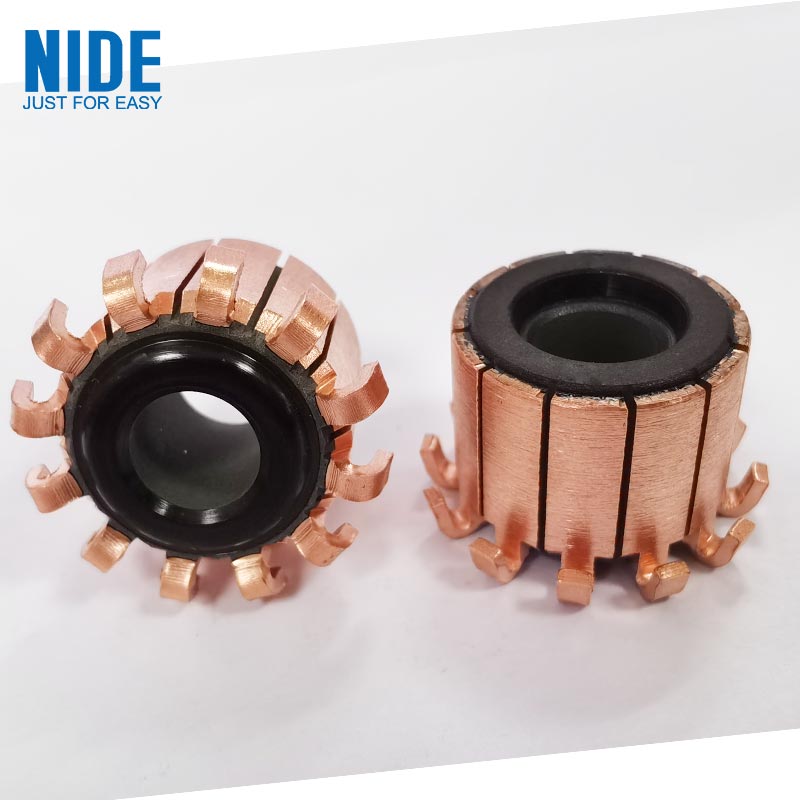

12x23.2x18mm Copper Bars Alternator Electric Motor Commutator

Alternator Commutator parameters

| Product Name: | Alternator Electric Motor Commutator |

| Material: | Copper |

| Type: | Hook Commutator |

| Hole diameter : | 12 mm |

| Outer diameter: | 23.2mm |

| Height : | 18mm |

| Slices : | 12P |

| MOQ: | 10000P |

Commutator Application

Commutators are used on Generators and DC motors. They are also used on some AC motors such as the synchronous, and universal motors.

Commutator Picture

Working Principle Of Commutator

The commutator is conventionally made by assembling hard-drawn copper sectors inter-leaved with sheet mica, these separators being ‘undercut’ by about 1 mm. The brushes, of a suitable carbon/graphite content, are mounted in boxes with spring loading to hold them against the commutator surface with a medium to strong pressure depending on the application.

Action Of The Commutator

The action of the commutator is to convert the slip frequency generated in the armature windings back to supply frequency across the brushes. The brushes are connected to the main power supply through an induction regulator which provides the link between the variable voltage at the commutator brushes and the constant voltage supply. This regulator is then used to inject a voltage into the armature winding via the brushes and causes the speed to be varied in relation to the injected voltage. At speeds below synchronous, power is drawn from the armature and returned to the supply; at super-synchronous speeds power is drawn from the supply and fed into the armature.

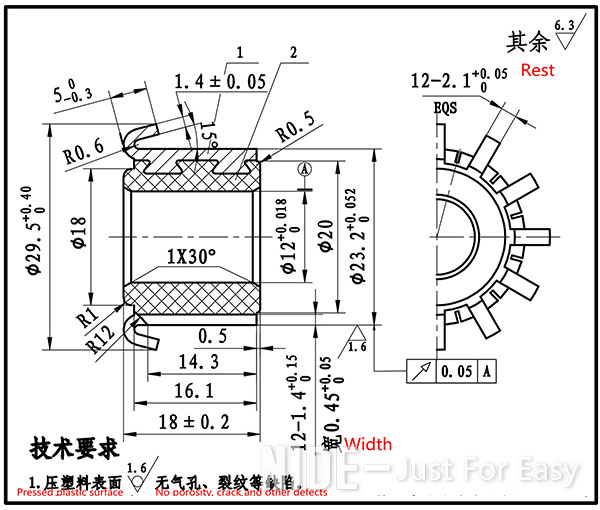

Information needed for commutator inquiry:

It will be better if customer could send us detailed drawing including below information.

1. Commutator dimension: OD, ID, total height, and copper height, bar number.

2. Commutator type: hook type, raiser type or planner

3. Copper material: Agcu/ Cu

4. Commutator applications

5. Required quantity

6. Copper bush needed or not

7. Other technical requirement.

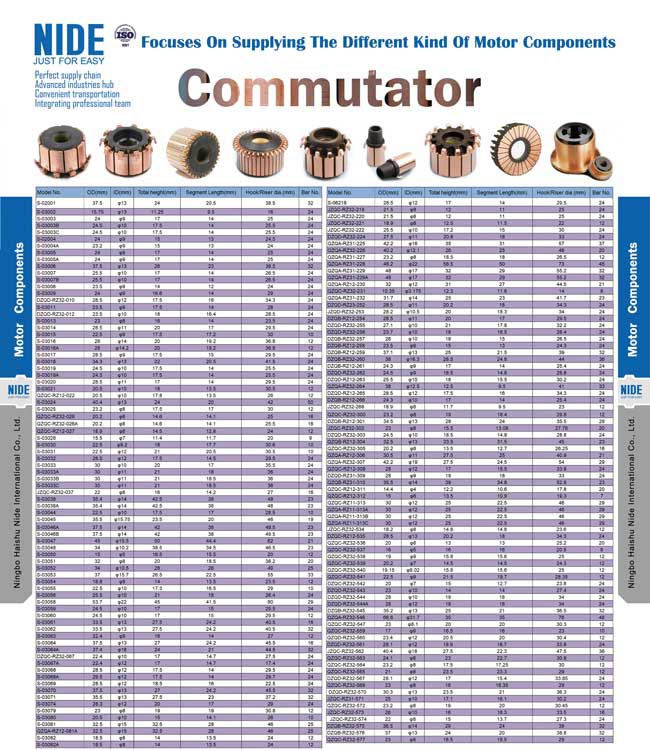

Nide produces more than 1200 different types of motor commutator, including hook type, riser type, shell type, planar type, ranging from OD 4mm to OD 150mm and we are professional in manufacturing commutator for many years. The commutators are widely applied to automotive industry, power tools, household appliances, and other motors.If our existing models are not suitable for you, we could also develop new tooling according to your drawing and samples.

Besides, we can supply the full range of motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper material, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com