PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

NDPJ-HXQ-C149A

The hook motor commutator is used in speed control device motor, is particularly intended for household sewing machines and industrial sewing machines.

Categoryes: Commutator

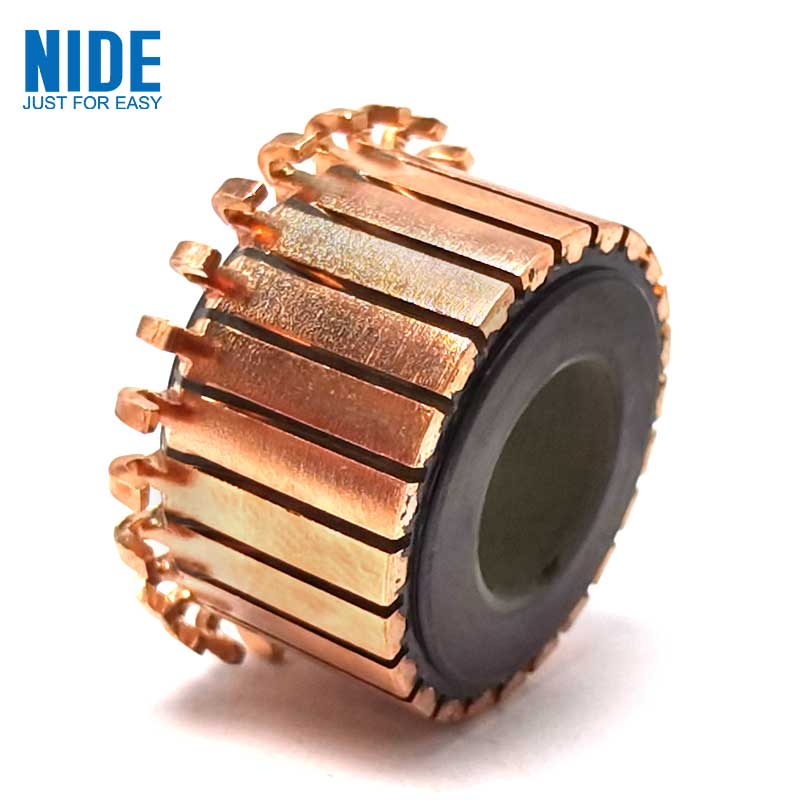

DC Motor Commutator Household Sewing Machine Hook commutator 10*21.5*14.5mm

DC Motor Commutator Introduction

The hook commutator is suitable for Household sewing machine motor. Our motor commutators are produced on automated lines or dedicated production cells for consistent quality.NIDE can offer an extensive line of quality motor commutators to meet your high volume, high performance criteria.

DC Motor Commutator Application

The hook commutator is used in speed control device motor, is particularly intended for household sewing machines and industrial sewing machines. Our motor commutator is also suitable for hair dryer, mixer, vacuum cleaner, washing machine, source juice machine ,whisk, juicer, soymilk, and for other household appliances.

DC Motor Commutator Features

1. To be free from void(bubble) more than 1mm and cracks in molded resin surface, but air hole(depth 1.6± 0.1, width 0.5± 0.05 ) should be tolerated.

2. Voltage Test: Bar to bar at 600V, 1s, and bar to shaft at 3750V, 1 min, there will be no break down or flash

3. Spin Test: Under 180±2 ℃ , 46800rpm, 10mins, the max change in OD is 0.01mm and the max deviation between bar to bar is 0.007.

4. Insulation Resistance: The insulation resistance is greater than 50MΩ under 500V.

Working principle of DC motor commutator

The segments of the motor commutator are usually made of copper and are separated from each other by mica insulation. The mica is cut so that it lies below the copper segments. Slots are cut in the riser on the commutator to facilitate the soldering of the ends of the coils. There are twice the number of segments on the commutator as there are slots in the laminated core for the coils.

On DC and most AC motors the purpose of the commutator is to insure that the current flowing through the rotor windings is always in the same direction, and the proper coil on the rotor is energized in respect to the field coils. By mechanically positioning the brushes on the commutator, an angle of displacement can be set up between the magnetic force of the field windings and the magnetic force of the rotor windings.

DC Motor Commutator Details

| Product Name: | 24 bars sewing machine motor commutator |

| Material : | silver /copper /mica/ plastic |

| Color : | Standed color |

| Type: | Hook Commutator, Segmented Commutator, Plane Commutator |

| MOQ: | 5000 Piece |

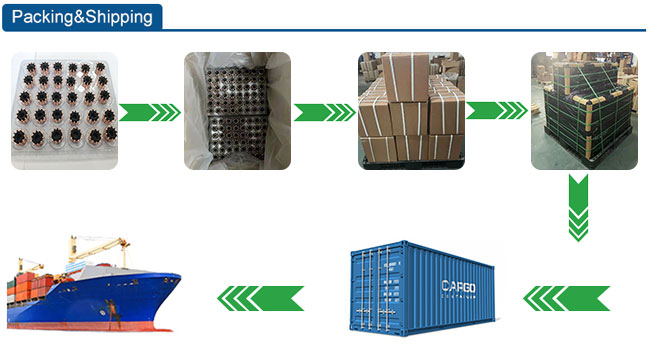

| Delivery time | According to the order quantity |

DC Motor Commutator Pictures

Information needed for commutator inquiry:

It will be better if customer could send us detailed drawing including below information.

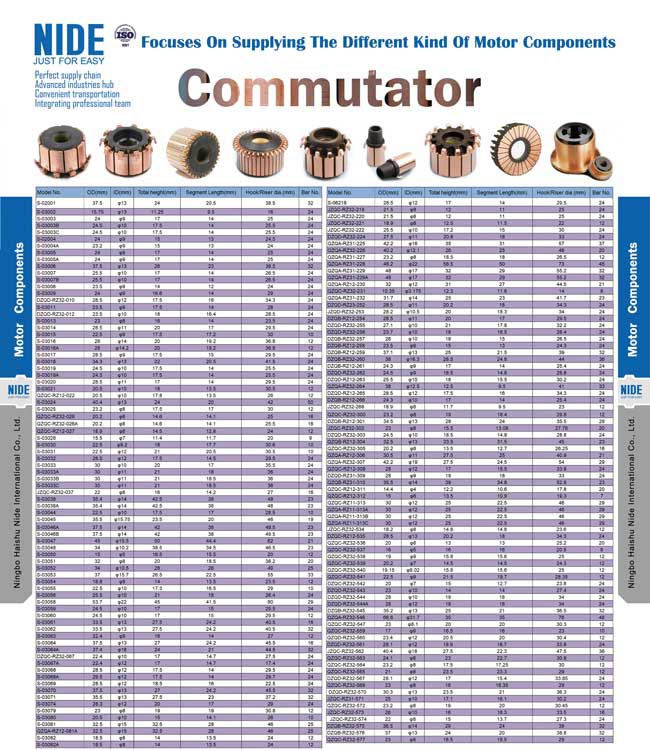

1. Commutator dimension: OD, ID, total height, and copper height, bar number.

2. Commutator type: hook type, raiser type or planner

3. Copper material: Agcu/ Cu

4. Commutator applications

5. Required quantity

6. Copper bush needed or not

7. Other technical requirement.

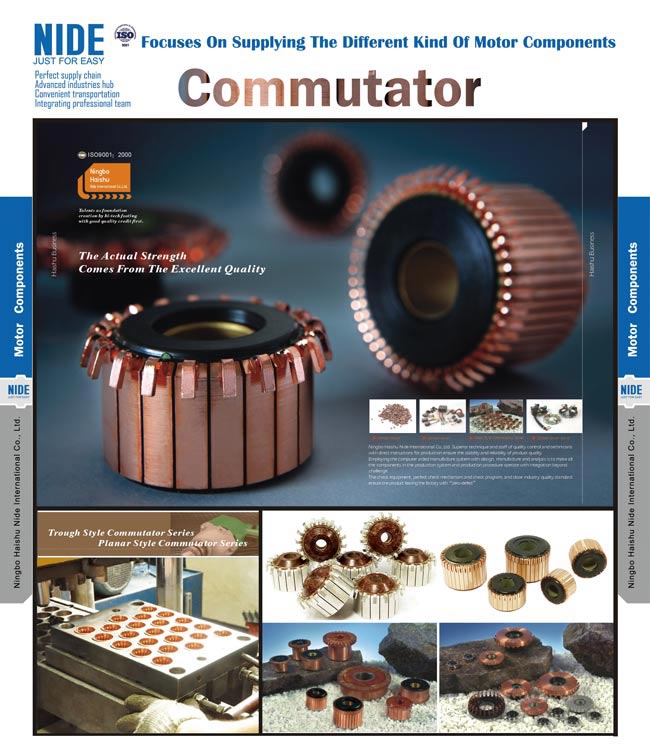

Nide produces more than 1200 different types of motor commutator, including hook type, riser type, shell type, planar type, ranging from OD 4mm to OD 150mm and we are professional in manufacturing commutator for many years. The commutators are widely applied to automotive industry, power tools, household appliances, and other motors.If our existing models are not suitable for you, we could also develop new tooling according to your drawing and samples.

Besides, we can supply the full range of motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper material, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com