PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

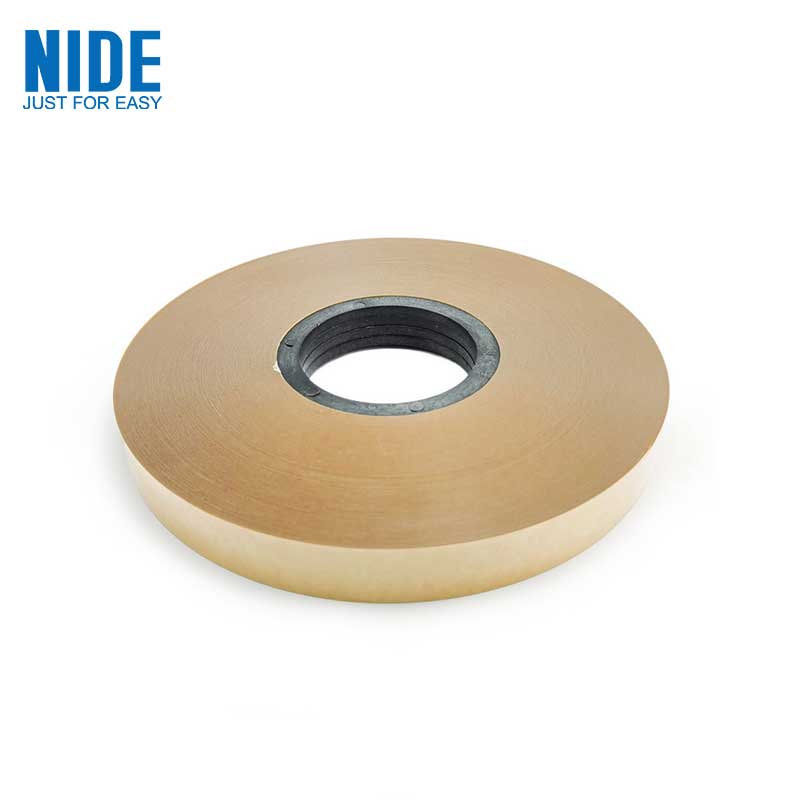

NDPJ-JYZ-PM

PM insulation paper is a two-layer composite material composed of a layer of polyester film and a layer of electrical insulating paper, bonded with F-class resin. It has good dielectric properties and is suitable for the insulation between slots and turns of small motors. Pad insulation.

PM Insulation Material Electrical Insulating Paper For Motor Winding

Product Description:

PM insulation paper is a two-layer composite material composed of a layer of polyester film and a layer of electrical insulating paper, bonded with F-class resin. It has good dielectric properties and is suitable for the insulation between slots and turns of small motors.

Application of PM insulating paper:

Blister, folding box, packaging, printing, card making, high and mid-range tapes, labels, office supplies, collar linings, electronics, insulation, flexible circuit printing, monitor screensavers, membrane switches, film windows, printed films, Imposition film base, self-adhesive backing paper, glue coating, silicon coating, motor gasket, cable tape, instrument panel, capacitor insulation, furniture stripping film, window film, protective film inkjet printing, decoration, printing film base, advertising film Base, digital inkjet, magnetic card, light box, tape leader, IC card, signage, composite, printing, gluing, coated glass, reflective sheet, electronic board, die-cutting, printing industry, packaging industry, advertising industry, electronic industry, etc. The application is very wide.

Advantage:

1. The color is uniform, the surface is smooth and flat, and the color does not fade.

2. Odorless, tasteless, non-toxic, smooth surface, good flexibility, no water ripples on the surface, no crystal points, no double phase whitening, good impact resistance strength (good impact resistance strength at low temperature).

3. Corrosion resistance, excellent insulation, excellent mechanical properties, high rigidity, hardness and toughness, puncture resistance, friction resistance, small thickness tolerance, low thermal shrinkage rate, firmness, low shrinkage, low water absorption, smooth and shiny surface , Creep resistance, fatigue resistance, friction resistance, dimensional stability are very good, high temperature and low temperature resistance, high chemical resistance, oil resistance, good air tightness and fragrance retention, and is also a commonly used barrier property One of the composite film substrates.

Stator insulating paper sepcification

Thickness 0.13mm-0.35mm

Width 5mm-100mm

Thermal class F

Working temperature 155 degree

Color Yellow

|

Properties |

Unit |

Parameter |

|||||||||

|

Insulation paper thickness |

MM |

0.09 |

0.11 |

0.15 |

0.19 |

0.20 |

0.23 |

0.25 |

0.30 |

0.36 |

0.41 |

|

Thickness deviation |

MM |

±0.01 |

±0.01 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.03 |

±0.03 |

±0.04 |

±0.04 |

|

Grammage and deviation |

GSM |

93±9 |

113±11 |

183±18 |

218±22 |

253±25 |

288±29 |

308±31 |

393±39 |

463±46 |

533±53 |

|

Film thickness |

MM |

0.036 |

0.050 |

0.100 |

0.125 |

0.150 |

0.175 |

0.190 |

0.250 |

0.300 |

0.350 |

|

Breakdown voltage |

KV |

≥5 |

≥6 |

≥9 |

≥10 |

≥11 |

≥13 |

≥14 |

≥16 |

≥18 |

≥22 |

|

Tensile strength (MD) |

N/CM |

≥60 |

≥80 |

≥150 |

≥190 |

≥220 |

≥250 |

≥280 |

≥330 |

≥350 |

≥380 |

|

Tensile strength (TD) |

N/CM |

≥40 |

≥70 |

≥110 |

≥140 |

≥150 |

≥160 |

≥180 |

≥280 |

≥300 |

≥330 |

|

Tensile strength after folding (MD) |

N/CM |

≥40 |

≥70 |

≥110 |

≥140 |

≥165 |

≥190 |

≥240 |

≥280 |

≥300 |

≥330 |

|

Tensile strength after folding (TD) |

N/CM |

≥20 |

≥50 |

≥90 |

≥110 |

≥115 |

≥120 |

≥130 |

≥180 |

≥200 |

≥230 |

Information needed for insulation material inquiry

It will be better if customer could send us detailed drawing including below information.

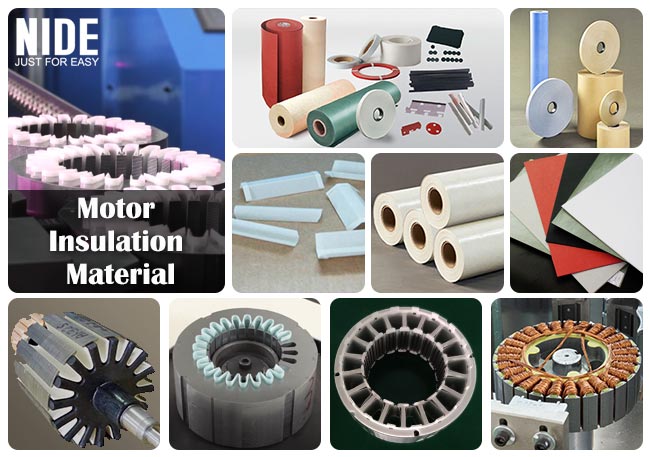

a. Insulation material type: insulation paper, wedge, (including DMD,DM, polyester film, PMP,PET, NHN , NMN ,PM ,Red Vulcanized Fiber,)

b. Insulation material dimension: width, thickness, tolerance.

c. Insulation material thermal class: Class F, Class E, Class B, Class H , Class C

d. Insulation material applications

e. Required quantity: normally its weight

f. Other technical requirement.

We also supply different types of electrical insulation materials for stator or armatures, such as insulation paper and insulation wedge with different class degree. DMD Class B/F, DM Class B/F, Polyester film Class E, Red Vulcanized Fiber Class A, NH& NHN, etc

Besides, we can supply the full range of motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper material, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com