PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

ND-HMPX-1

The motor stator production line is used for the manufacture of new energy vehicle hairpin motor stators.

Fully Automatic EV Car Hairpin Motor Stator production line

The stator production line is used for the copper wire hairpin motor stator manufacturing. Hairpin motors are currently mainly used in new energy vehicles.The entire manufacturing process of the hairpin motor stator is highly automated and intelligent

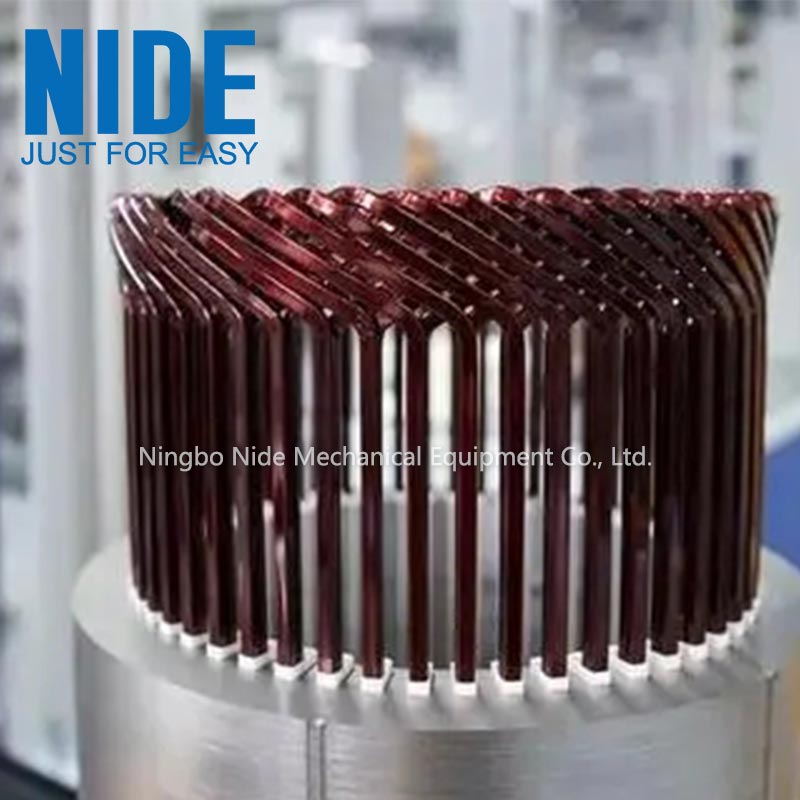

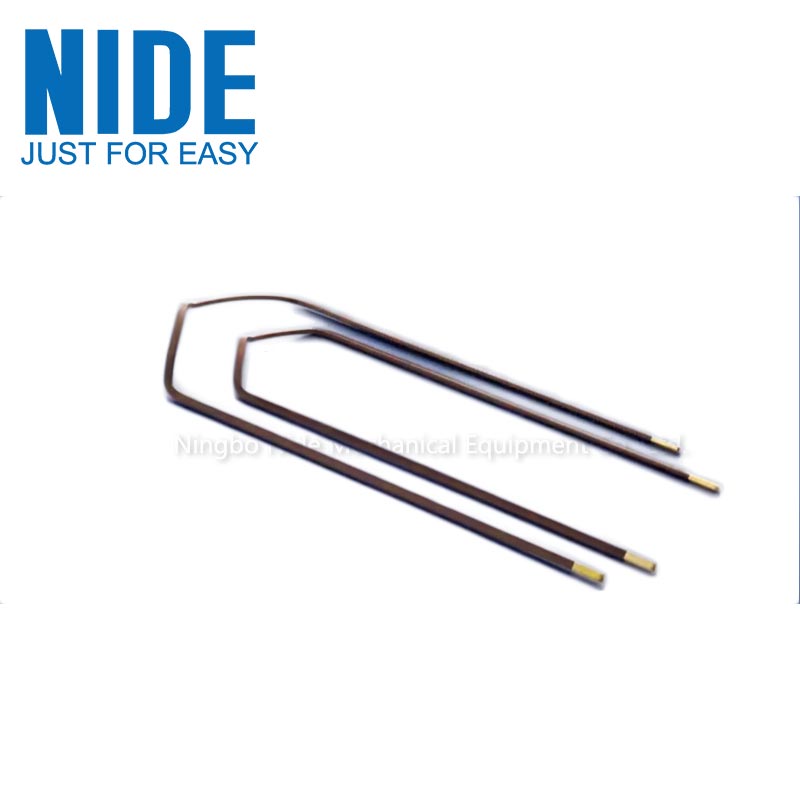

The hairpin motor stator winding is the shape like a hairpin. In the motor stator manufacturing process, the winding is first made into a hairpin-like shape and then inserted into the stator slot, and then the ends of the hairpin are welded on the other end according to the design.

The hairpin motor process is threading, so the notch does not need to be fully opened, and the half-opened slot is beneficial to reduce the cogging torque. The winding structure of the hairpin motor stator is composed of n hairpins during the manufacturing process. The traditional flat copper wire motor is a formed winding;

Product Information

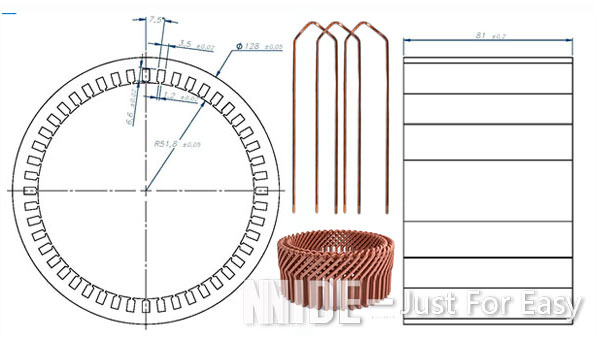

| Name | Hairpin stator production line |

| Stator O.D. | 128mm (customized ) |

| Stator I.D. | 103,6mm (customized ) |

| Stack length | 81mm (customized ) |

| Slot | 48 (customized ) |

| Wire specification | customized |

| Layer | customized |

| Wire inserting end height | customized |

| Welding end height | customized |

| Wire types | customized |

| Power terminal | customized |

| Insulation Paper | customized |

| Star dotted line | customized |

| Twisting angle | customized |

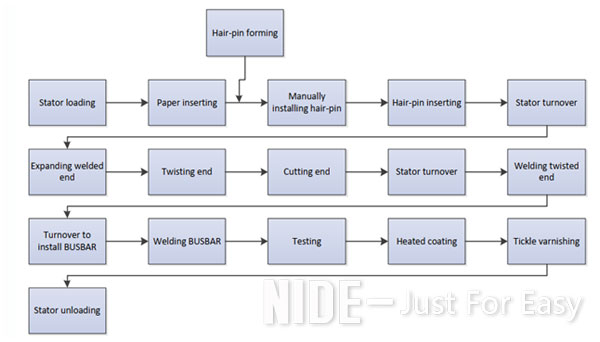

1.Hairpin stator manufacturing Line Process

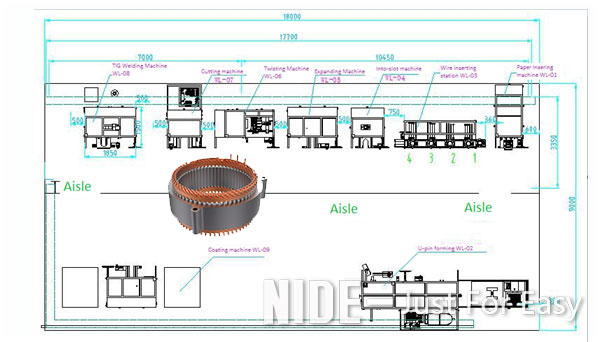

2. Hairpin stator manufacturing Line Layout

Layout Area for the hairpin motor stator production line

Length 18 m / Width 9 m / Height around 2.5 m / Area around 162 m2

3. This hairpin motor stator production line includes the following models:

a. Paper inserting machine

b. U-pin wire forming machine

c. Wire inserting station

d. Wire inserting machine

e. End expanding machine

f. End twisting machine

g. End cutting machine

h. TIG welding machine

I. Stator coating machine

Nide provides turn-key service and technical consultance for motor production technology, it covers varies type motors. We could accomplish tailored and innovative solutions to meet all quality and production requirements, aim at making motor production easier.

Our fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com