PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

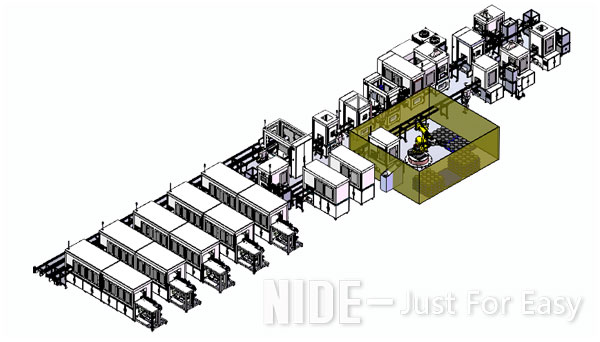

ND-HMPX-2

This stator production line is mainly suitable for water pumps ,submersible pump motor and deep-well pump motors with long stack length.

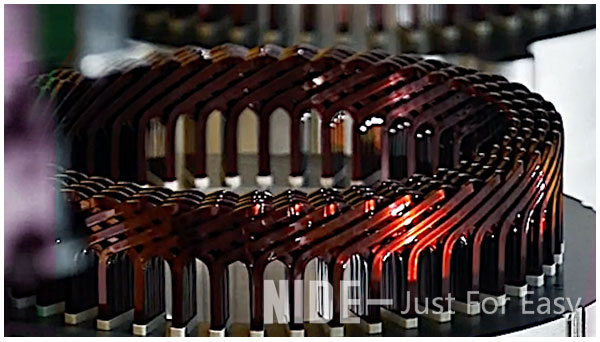

Hairpin Motor Stator Production Line For New Energy Vehicle Flat Wire Motor Manufacturing

The Hairpin Motor Stator Production Line is suitable for New Energy Vehicle (EV motor) hairpin stator manufacturing.

Hairpin Motor Stator Production Line Features

With highly automated, informationized, flexible and intelligent.

The Hairpin Motor Stator Porudction Line is equipped with MES system.

Adopt to produce 2-10 layers hair pin stators

Hairpin Motor Stator Production Line Specification

C/T 100s, occupied floor: 30m x 12m

Hairpin Motor Stator Production Line Process

Paper inserting--hair pin forming--hair pin coil inserting--end twisting--hair pin flat cutting--hair pin welding-- busbars welding -- coil testing -- coating/trickling -- performance test

Hairpin Motor Stator Production Line Technical Proposal

B type paper inserting machine

B type paper hi-pot test & end expanding machine

Hair pin forming machine

Hair pin coil inserting machine

Hair pin end expanding machine

Hair pin end twisting machine

Perpendicularity straightening machine

Perpendicularity testing machine

Hair pin flat cutting machine

Hair pin laser welding machine

Coil testing machine

Trickling machine

Busbars welding machine

Laser marking machine

Stator tester (includes PDIV test)

Nide provides turn-key service and technical consultance for motor production technology, it covers varies type motors. We could accomplish tailored and innovative solutions to meet all quality and production requirements, aim at making motor production easier.

Our fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com