PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

ND-100TB

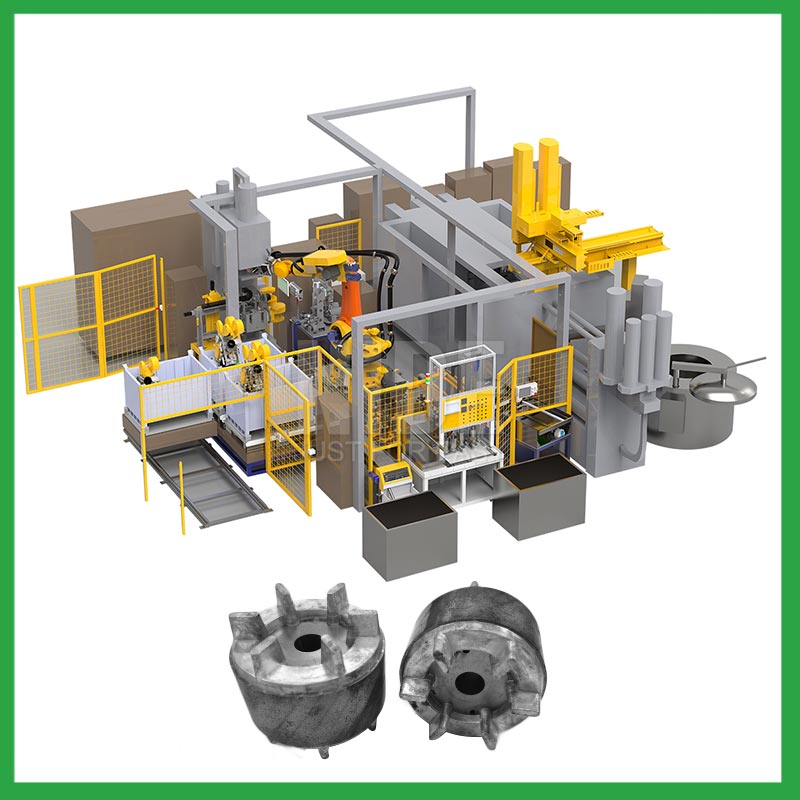

The aluminium rotor die-casting line is suitable for casting aluminum of various types of motor rotors, and can realize the integrated production of fully automatic rotors.

Fully automatic aluminium rotor die-casting line solution

The aluminium rotor die-casting line is suitable for casting aluminum of various types of motor rotors, and can realize the integrated production of fully automatic rotors.

The aluminium rotor die-casting line is easy to operate. It only takes one day for green hands becoming practician. It takes about 10min to change mould. It is high working efficiency and equipped with 4 aluminium casting stations , 300-500pcs/hour.

During die casting, machine will transfer the residual aluminium to the aluminium furnace in time automatically. Since the residual aluminium still has a high temperature. It is saving time, cost and high security.

Aluminium Rotor Die-Casting Line Application

The aluminium rotor die-casting line is suitable motor aluminium rotor manufacturing. Especially suitable for induction motors, brushless motors, synchronous motors, permanent magnet motors, compressors, washing machines, etc.

Aluminium Rotor Manufacturing Process

Manually loose lamination weighing→ Putting truss into turntable→ Robot loading→ Into tooling→ Die-casting→ Casted rotor out of tooling→ Putting into integrated machine→ Weighing, marking codes, inspecting and stamping→ Putting into pressing machine→ False shaft pulling out→ Oil spraying→ Pick and load real shaft→ Putting pressure head→ Pressing real shaft→ Taking out pressure head→ Unload rotor to finished box

AluminIum Rotor Die Casting Line Technical Parameters

| 一、Specification | |||

| No. | Item | Unit | 100T specification |

| 1、Main cylinder: | |||

| 1 | main cylinder mold lock force | KN | 630 |

| 2 | main cylinder mold lock travel | mm | 400 |

| 2、Injecting cylinder: | |||

| 1 | Injecting cylinder travel | mm | 150 |

| 2 | Injecting cylinder injecting force | KN | 400 |

| 3 | Injecting force(Min-Max) | KN | 70-400 |

| 4 | capacity | L | 25 |

| 5 | aluminum depot OD(Max) | mm | 100 |

| 6 | punching head OD(Max) | mm | 100 |

| 7 | aluminum depot capacity(Max) | kg | 2 |

| 8 | Injection punching head travel distance | mm | 60 |

| 9 | cycle time | s | 15-20 |

| 10 | Rotor OD | mm | Max 100 |

| 11 | Rotor stack height | mm | Max 100 |

| 3、Motor and pump: | |||

| 1 | Pump motor power | KW | 7.5+7.5 |

| 2 | Divider motor powder | KW | 1.5 |

| 3 | Oil pump (plunger pump) | L | 40Y+40Y |

| 4、Machine dimension: | |||

| 1 | Main frame(L*W*G) | mm | 2000*2100*2700 |

| 2 | assembly of oil tank and electric appliance(L*W*G) | mm | 2100*1500*1500 |

| 3 | turntable OD | mm | 1000 |

| 5、Cooling pump specification: | |||

| 1 | Submersible pump power | KW | 1.5 |

| 2 | Submersible pump rate of flow | M3/H | 5 |

| 3 | Submersible pump water pressure | MPa | 0.4 |

| Remark: the max pressure of this machine is 25Mpa / Submersible pump power 220/380V Option |

|||

Fully automatic aluminium rotor die-casting line video

Nide provides turn-key service and technical consultance for motor production technology, it covers varies type motors. We could accomplish tailored and innovative solutions to meet all quality and production requirements, aim at making motor production easier.

Our fully automatic motor assemble line is suitable for varies type induction motor assembly, BLDC motor assembly, universal electric motor and DC motor assembly, It could automatically assemble the rotor, armature, stator and motor components together . It is used for washing machine motor, fan motor, BLDC motor, DD motor, electric bicycles motor , electric vehicle motor , hub motor, DD BLDC washing machine motor , compressor motor, vacuum cleaner motor, power tool motor, wiper motor, mixer motor, RO pump motor, NEMA motor, DC motor, etc. It features fast, efficient, accurate winding, easy set-up, user-friendly programming and tooling flexibility.

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com