PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

R2QL1-120-150C

The automatic electric motor stator coil winding and insertion machine has 3 coil winding stations and 1 coil insertion stations, it is suitable for for lifting machinery, electric drainage motor,table fans motor, miniature induction motors , air conditioner motors, washing machine motors, compressor motors,etc.

Auto Induction motor stator coil winder and insertion machine

The automatic electric motor stator coil winding and insertion machine adopts 4 stations design with 3 coil winding and 1 coil insertion. It can save labor cost, high efficiency, and can fulfill the 2-pole, 4-pole and 6-pole three-phase motor coil winding. The product is mature in technology, advanced in technology, reliable in quality, and convenient to use and maintain.

1. The main Features and Functions

The automatic stator coil winding and insertion machine adopts a full set of servo motor drive to ensure the accuracy and stability of the machine operation. The coil insertion station adopts dual power push line to meet the production of high slot full rate products.

The stator coil windier and insertion machine is specially designed for the stator winding of motor, and integrates winding, grooved wedge and ruled line.

The stator coil windier and insertion machine adopts four-station design with three-head winding and one-head coil inserting. With 4 stations working at the same time, The machine will be save labor cost, high efficiency, and can fulfill the 2-pole, 4-pole and 6-pole three-phase motor coil winding.

This machine can simultaneously realize two sets of wires to be wound at the same time, and adds two insulation paper inserting stations, which realizes the function of adding the phase insulation at the same time, and reduces the manual operation of the post process.

During winding, the coil will be auto wound to the tooling, so as to avoid the wire damage and snap caused by wire cross and disorder during manual wire transfer.

The coil winding and inserting station is controlled by the dual-power servo motor, and the parameters such as winding, pushing the line, pushing the height of the paper, and changing the product stack thickness can be set on the touch screen.

2. Application

This motor stator coil winding and insertion machine is suitable for lifting machinery, fans, various production machinery, electric drainage, various machine tools, miniature induction motors , air conditioner motors, washing machine motors, compressor motors, fan motors, generator motors, pump motors, ,agricultural and sideline products processing equipment.etc.

3. Technical parameters

| Product name | Automatic electric motor stator coil winding and insertion machine |

| Appropriate Wire | φ0.2-φ1.2mm |

| Stack Height | 30-80mm |

| Stator OD | ≤φ150mm |

| Stator ID | 40-80mm |

| Winding stations | 3 |

| Coil inserting stations | 1 |

| Height of Coil | 3 |

| Winding inserting mode | chained / same core |

| voltage | 380V 50/60Hz |

| Power | 15Kw |

| Dimension | (L)4050×(W)3000×(H)2500mm |

| Weight | ≈4000Kg |

4.The picture display

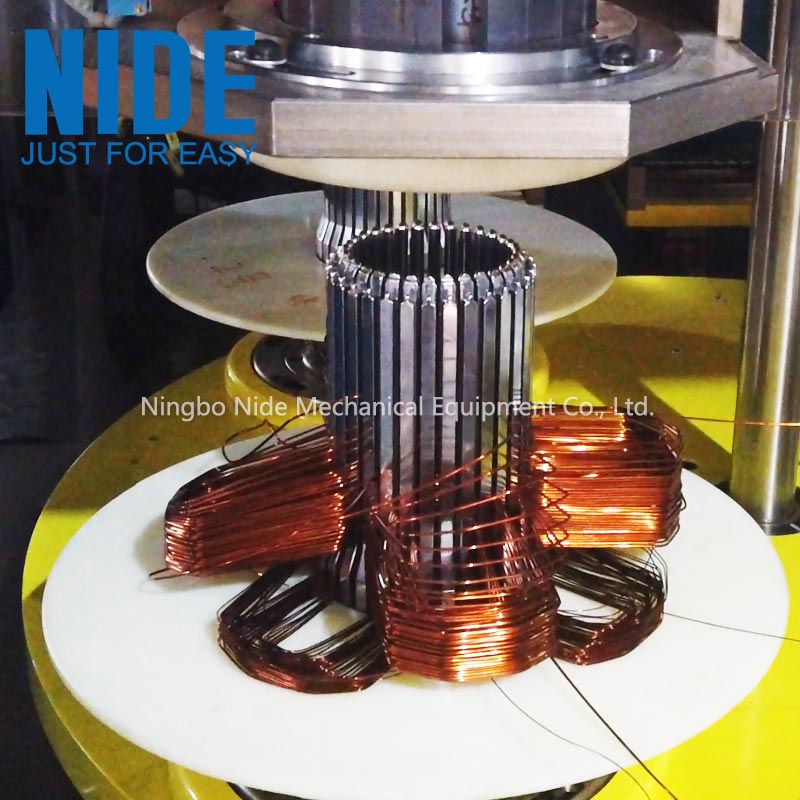

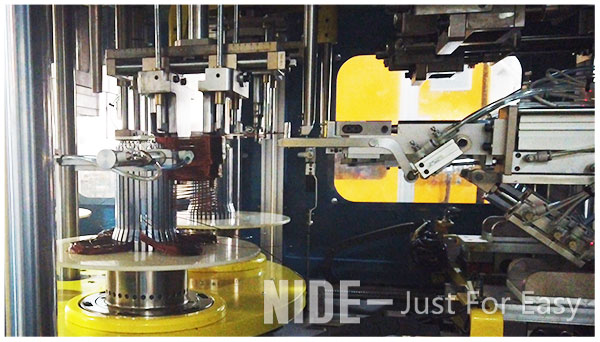

a. The stator coil winding process

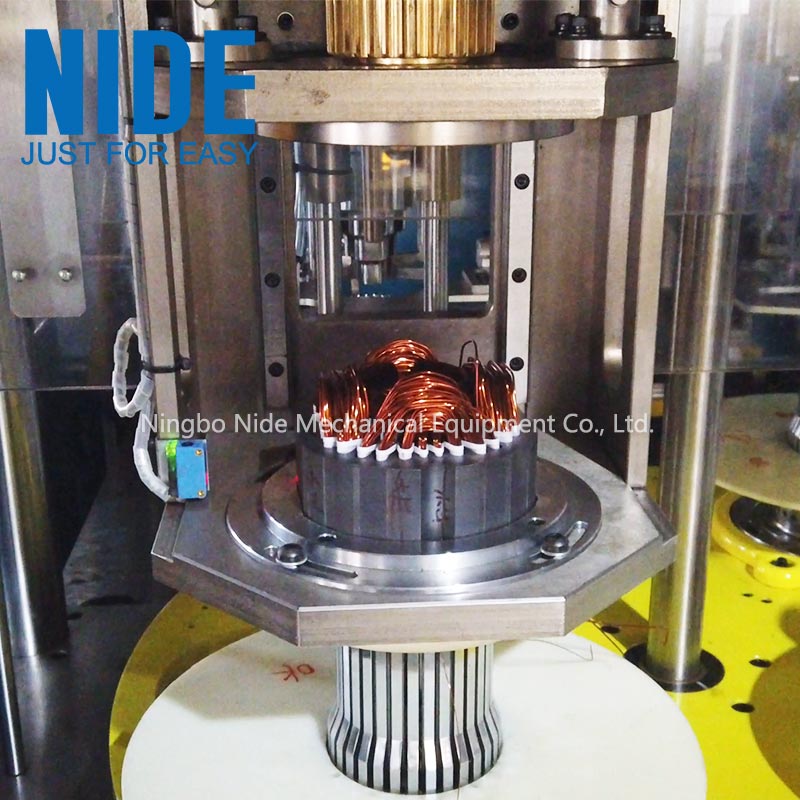

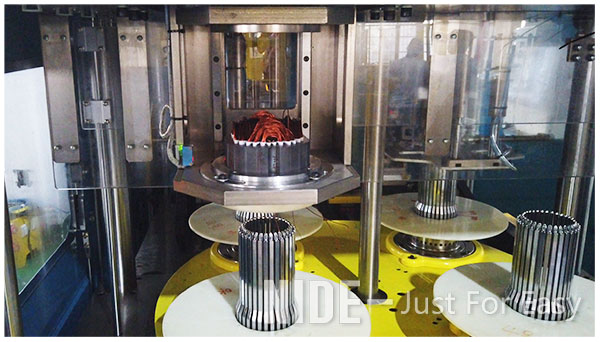

b. The stator coil inserting process

c. The stator after coil insertion

5.The stator coil winder and insertion machine video

![]()

| Contact us

Motor Manufacturing Machine Department