PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

ND-R2SW02B

The motor outer stator needle winding machine is suitable for outslot stator winding of brushless motor in many fields such as HM, medical equipment, household appliances and electric vehicles.

Brushless Motor Ouslot Stator Needle Winding Machine

(1) Machine induction:

This Brushless motor needle winding machine is designed for the BLDC motor stator coil winding. The out slot stator coil winder adopts double-position needle-type outer winding design. Customers can set parameters according to their own needs, such as automatic winding, multi-wire winding, Automatic indexing, automatic spanning, winding speed, etc.; simple operation and high production efficiency.

(2) Technical parameter:

|

Product name: |

BLDC armature rotor coil winding machine/ Needle winder |

|

Type: |

Automatic |

|

BLDC Armature I.D.: |

20-80mm (Other specifications can be specially designed) |

|

BLDC Armature O.D.: |

50-120mm(Other specifications can be specially designed) |

|

BLDC Armture stack length: |

10-80mm(Standard stroke) 100-200mm(Long stroke, special customization) |

|

Wire dia.: |

0.5-1.5mm(Other specifications can be specially designed) |

|

Applicable pole number : |

multipolar |

|

Motor winding mechod : |

Needle winding |

|

Winding stations : |

Two |

|

Spindle speeds : |

0--300 RPM (adjustable) |

|

Servo mechanism: |

Two 4.4KW Indexing Motor One 3KW Winding Motor with Brake 750W or so two wiring motor |

|

Voltage: |

380V/50HZ Three phase four wires |

|

Air pressure: |

0.5--1Mpa |

|

Power: |

20KW |

|

Dimension: |

1200*1360*1800mm (Length * width * height) Does not include wire rack |

|

Weight: |

600kg |

(3) Application:

The motor outer stator needle winding machine is suitable for outslot stator winding of brushless motor in many fields such as HM, medical equipment, household appliances and electric vehicles.

(4)Function and Characteristics:

1. The motor needle winding machine is sutiable for multi-pole BLDC armature coil winding. Manual loading and unloading, automatic clamping, winding and shearing.

2. The frame adopts thickened 4080 aluminum profile, and the table plate adopts cast iron to absorb vibration, even when winding at high speed, the vibration is very small.

3. Tooling and fixture parts adopt downward positioning mode, stable positioning and reliable tightening.

4. Wire clamping and wire cutting, line part structure compact, wire clamping and wire cutting is completed at one time;

5. Different stator and winding parameters can be quickly switched through the HMI to adapt to different stator requirements.

6. Quick change-overof tooling;(20 minutes with proficiency)

7. Full aluminum alloy protection

8. PLC control, fault display

9. The wire tightness is moderate, no injury, no breakage, ect.

10. The salt test of the product is carried out within 10 mA in one minute.

11. Equipment safety index: accord with CE standard.

12. Efficiency: 120 rev / min.

13. Beat: 5 minutes / BLDC rotor.

14. Noise: 60-70 decibels or less.

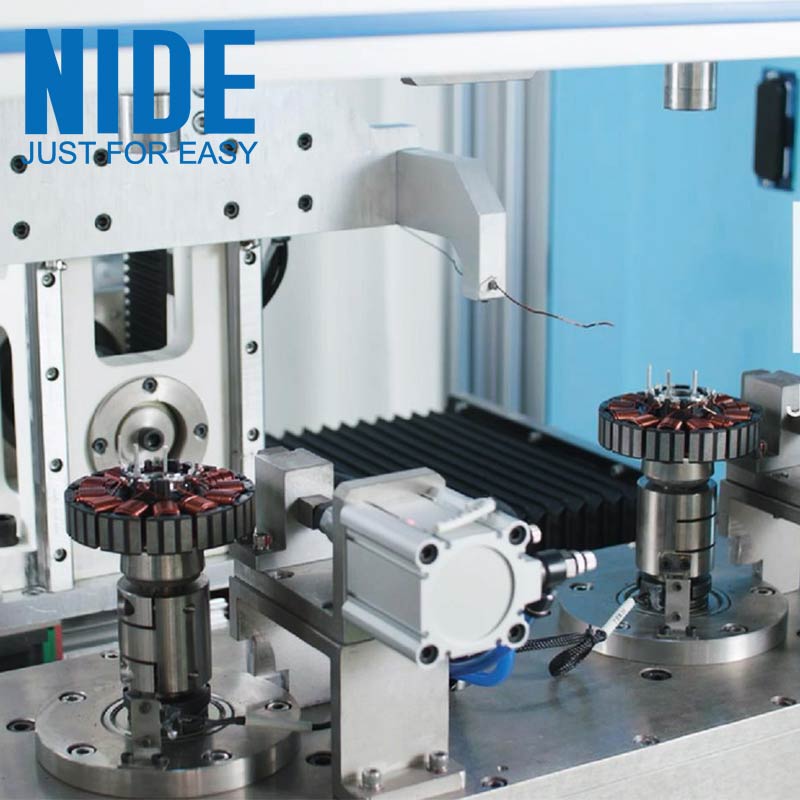

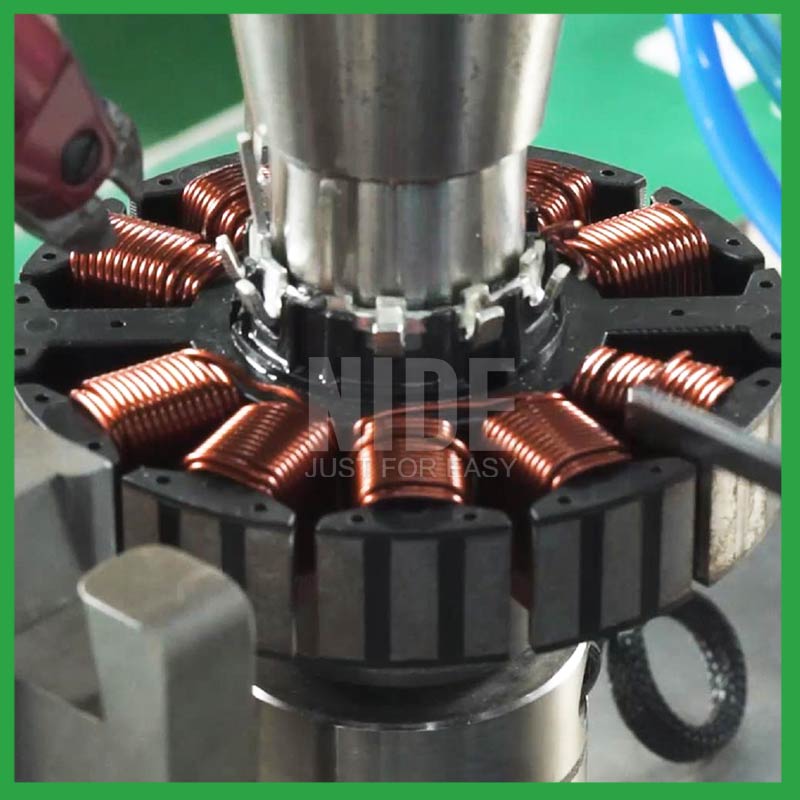

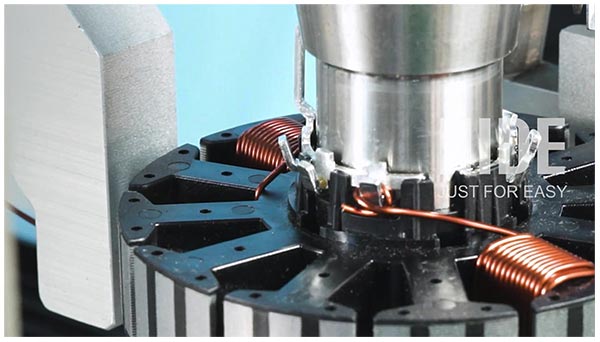

(5) The picture show:

1.The BLDC armature rotor needle winder

2.double stations brushless motor rotor winding machine

Needle Winding Machine Video

![]()

| Contact us

Motor Manufacturing Machine Department