PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Model:NDPJ-CW-79

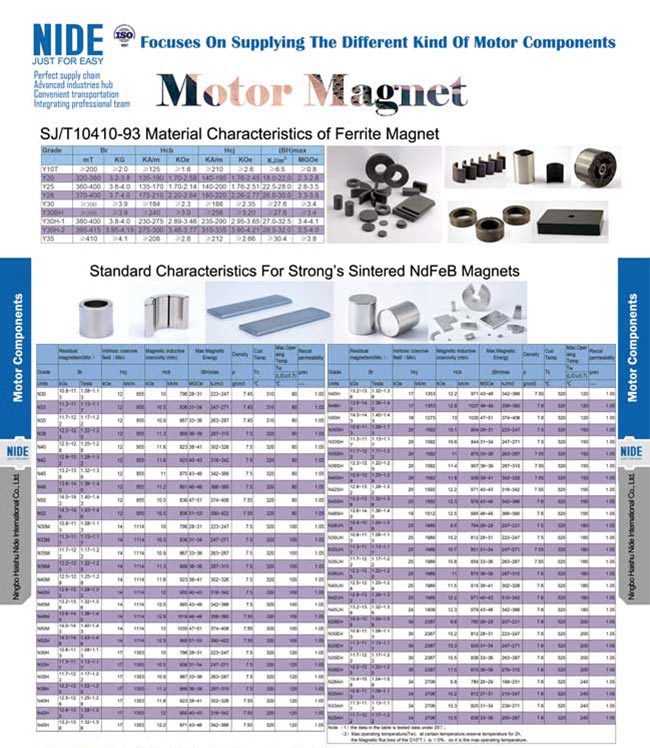

The sintered NdFeB magnetic materials are mainly used in the field of High-end motors, Electronic information, Automotive transmission, Consumer electronics, Electric machinery, Elevator, Aerogenerator, Medical and clean energy.

Categoryes: Magnet

Custome Sintered NdFeB Neodymium Magnets

The sintered NdFeB magnetic materials are mainly used in the field of High-end motors, Electronic information, Automotive transmission, Consumer electronics, Electric machinery, Elevator, Aerogenerator, Medical and clean energy.

The product has excellent stability, reliable mechanical properties and corrosion resistance. With key technologies for the development and industrialization of high remanence and high coercivity magnets, the products have excellent permanent magnetic properties.

Product Features

Shape: Block, Cylinder, Ring, Arc

Coating: NI, NICUNI, NI-NI, Gun color NI, ZN, Tin, Phosphorization, nickel, nickel copper nickel, double nickel, nickel gun color, zinc, electrophoresis and so on.

Feature: small, thin, long, special, tile products

Sintered NdFeB Manufacturing

1-Hydrogen Explosion

The hydrogen explosion process utilizes the hydrogen absorption characteristics of the rare earth intermetallic compound to cause the NdFeB alloy to expand and burst and break, thereby facilitating high-efficiency milling.

2-Milling

The air mill grinding powder is pulverized by the high-speed collision of the material itself, and has no wear and pollution on the inner wall of the grinding chamber, and the powder can be prepared with high efficiency.

3-Pressing

The compact is a compact that is pressed into a shape and size while maintaining the degree of grain orientation obtained in the orientation of the magnetic field as much as possible. The molding is performed by a forming magnetic field press and isostatic pressing.

4-Sintering

Sintering is a series of physical and chemical changes in the compact at high temperatures, changing the microstructure of the material to improve the magnetic properties of the material

5-Grinding machining

The NdFeB magnets obtained after sintering are all blanks and require further machining to obtain products of various sizes, sizes and shapes. NdFeB magnets are relatively brittle and have poor mechanical properties. Generally, they can only be used for grinding and cutting.

6-Chamfer

Mainly to remove the rough surface of the product and some mechanical defects, such as removing burrs, scratches, rust, scale, etc. on the surface of the part to improve the smoothness of the surface of the product, which facilitates the rapid, uniform and continuous deposition of the coating.

7-Remove oil

Remove oil and grease left over from various machining processes on the surface of the product.

8-Cleaning

The function is to remove the oxide on the surface of the product and roughen the surface of the metal to be plated to improve the bonding between the coating of the product and the substrate.

9-Activation

The activation is different from the acid etching, and does not interact with the metal, mainly to activate the surface, remove the oxide film formed by the product exposed to the air, and let the metal crystal appear in an activated state to ensure the bonding force between the plating layer and the body.

10-Eletro plating

Surface treatment of magnetic steel bodies of various shapes, such as galvanizing, nickel, nickel-copper-nickel, phosphating and electrophoresis, to ensure product appearance and corrosion resistance

We can offer a variety of NdFeB Magnet and Ferrite Magnet, If you need special magnetic tiles, we can also customize according to your needs.

About Motor component and accessories

NIDE can supply the full range of electric motor components such as commutator, ball bearing, thermal protector, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc.

![]()

| Contact us

Motor Parts Department

Email : emarketing@nide-group.com;marketing4@nide-group.com