PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

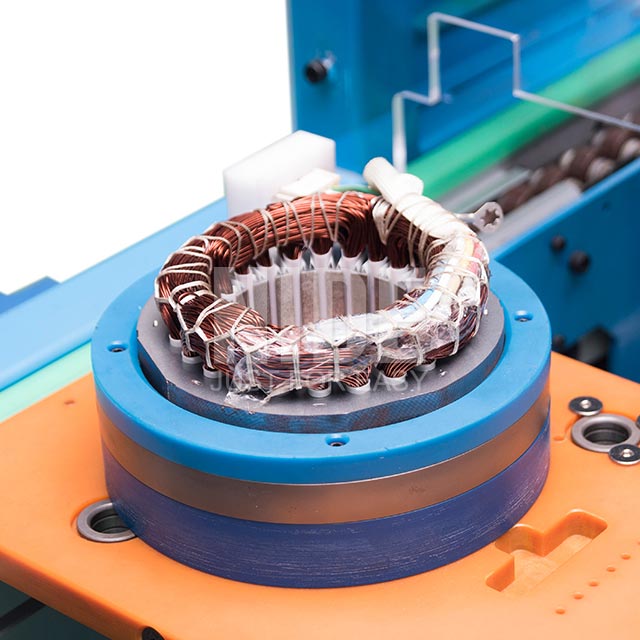

Fully automatic stator production line design feature:

Operator needed for this stator production line is far less than other machines or lines. The reduction of labor force will not affect the productivity. With a lower labor cost, and high productivity, this stator line improves the competitiveness for motor manufacturers.

Stator line main feature:

1.This production line is consisted of two parts, conveyor and stand-alone machines respectively. The stator transferring and transforming process is fulfilled by mechanical arm between conveyor and stand-alone machines. While machine action is accomplished by handshaking control between conveyor and stand-alone machines.

2.Each working station of this stator line has a self-contained control function, and can work independently.

3.The conveyor is equipped with an independent control system. It can lift, position, and stop stators.

4.With an automatic positioning function, the paper inserting station can load and unload stators.

5.Mechanical robot is used to connect the paper inserting station and auto coil inserting station during production. It is stable during running. Stator position put by the mechanical arm is more accurate.

6.Mechanical arm is used to connect the forming station and conveyor during production.

7.Mechanical arm is used to connect the lacing station and conveyor during production. Lacing and knotting process can be automatically done.

8.This stator line can automatically test the stator, then it will judge the qualified and unqualified stators so as to do next process.

This stator production line is consisted of several machines, paper inserting machine, stator coil winding and coil inserting machine, lacing machine, forming machine.

Technical data of stator paper inserting machine:

Stator stack length: 20~90mm

Stator OD: max 135mm

Stator ID: 20~90mm

Folding height/width: 2~4mm/4~7mm

Insulation paper thickness:0.188~0.35mm

Efficiency:≈0.5s/s

Power: 380V/50/60HZ 0.75KW

Machine weight: ≈200kg

Machine dimension: (L)1200*(W)650*(H)1100mm

Main technical data of stator coil winding and coil inserting machine

Stator OD:≤φ150mm

Stator ID:≤φ110mm

Stack Height:30-120mm

Height of Coil:3

Appropriate Wire:φ0.18-φ1.2mm

Winding inserting mode:chained /same core

Pitch time:≤40s/pc

Air Pressure:0.6-0.8MPa

Power supply:380V 50/60Hz 15Kw

Weight ≈4000Kg

Dimension:(L)2000×(W)1300×(H)2300mm

Technical data of stator lacing machine

Stator OD:φ40-φ160mm

Stator ID:≤100mm

Stack Height:30-160mm

Height of Coil:≤65mm

Pitch time:≤14s/pc(24 slots)

Air Pressure:0.4-0.6MPa

Power supply:380V 50/60Hz 6Kw

Weight:≈1500Kg

Dimension:(L)2000×(W)1100×(H)1900mm

Technical data of forming machine

Stator ID: 30~110mm

Stator OD: Max. 160mm

Stator stack length: 20~200mm

Winding overhang: Max 45mm

Displacement of cylinder: 20L/min

Power: 380V/50/60HZ 3.75KW

Machine weight: about 500Kg

Machine dimension: (L)1300*(W)1000*(H) 2400mm

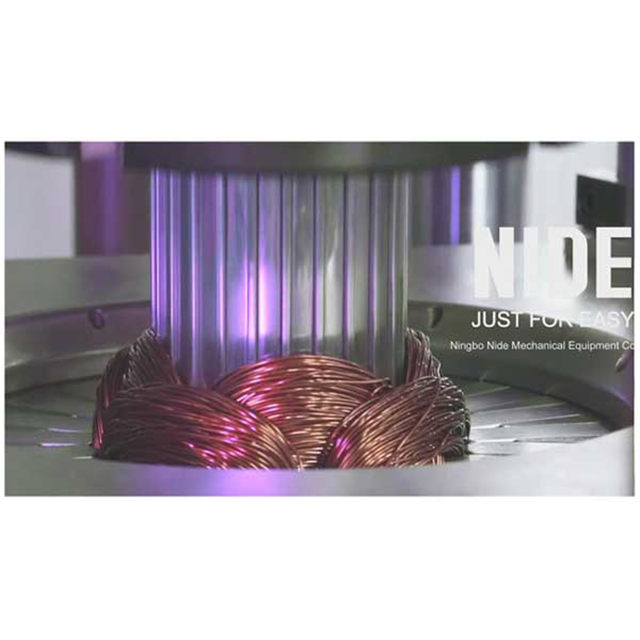

The motor stator manufacturing assembly productionl line youtube video

![]()

| Contact us

Motor Manufacturing Machine Department

Email : emarketing@nide-group.com;marketing4@nide-group.com