PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International Co., Ltd is a professional ball bearing manufacturer in China, exporting various high-precision bearings to target industries around the world since 2010. The factory is located in Suzhou, with a factory area of 9000 square meters and 102 employees. It mainly produces single machine and fully automatic production lines for external rotor production machines,motor stator,motor assembly line,BLDC motor winding machine and other customized machine tools or production lines.

We has professional technology and rich experience in quality control, customs clearance, commodity inspection, cargo transposition, insurance.We has rich stocks and is able to provide long tern stable supply, including rapid and urgent cargo handing . With companies in Europe, America , Japan and Korea, we are an integrated supplier of bearing, marketing all over the world.

| Parameter | Information |

|---|---|

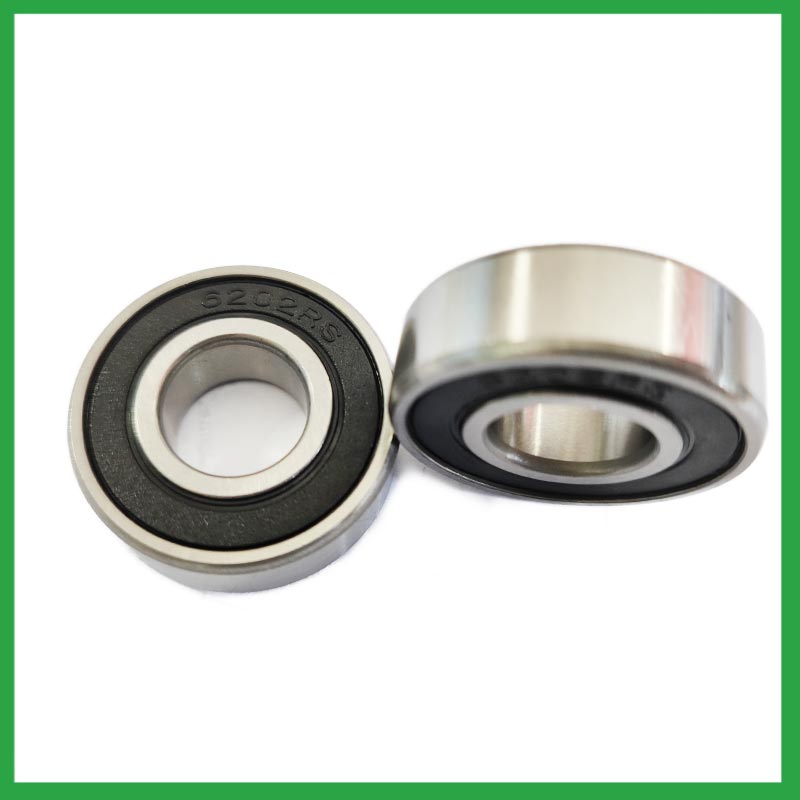

| Product Name | 10 mm id ball bearing |

| Brand Name | NIDE |

| Place of Origin | Ningbo,China |

| Material | ceramics, etc. |

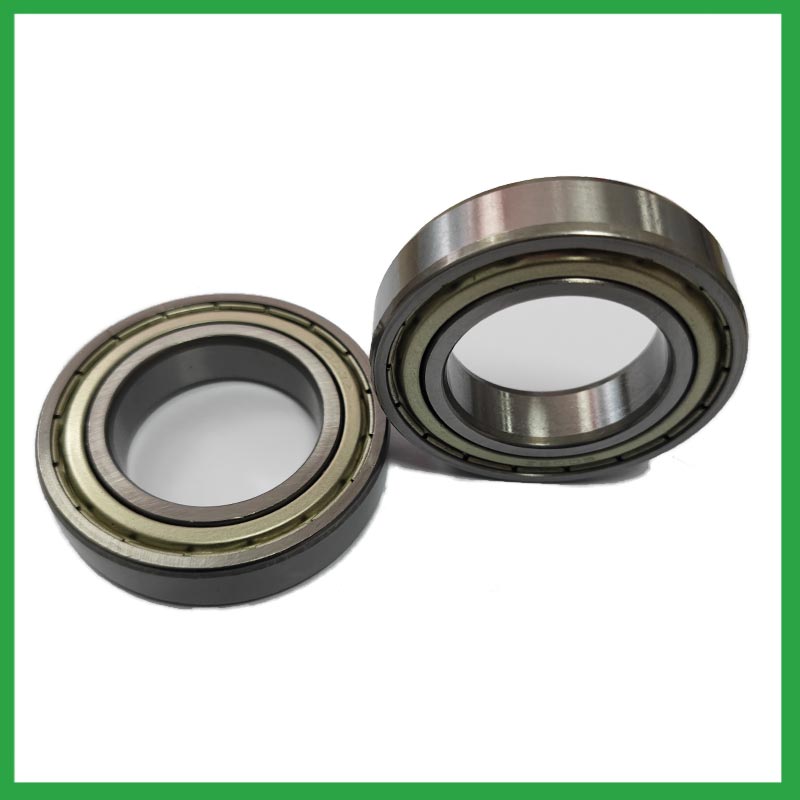

| Structure | Deep Groove |

| Color | Customized Color |

| Delivery Time | 5-7days |

| Port | Ningbo/Shanghai |

| Export region | Africa,America,Europe |

| Export Country | India,Brazil,South Korea,Singapore,Poland,Guernsey,Azerbaijan,Netherlands...etc |

| Application | chemical equipment, etc. |

| OEM/ODM | Yes |

| Size | Customized size |

| Stock | In Stock |

| Feature | Low Noise,High speed...etc |

| MOQ | 10 pieeces(Specific according to the model) |

| Certification | ISO9001,CE-stator coil winding machine,ISO9001:2015 certificate,etc |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lubricate | Oil Grease |

| Packaging Details | Suitable for sea transportation |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of 10 mm id ball bearing is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

During the disassembly process, the outer shell should be kept intact to avoid unnecessary damage;

When replacing installation components, attention should be paid to the accuracy of the support components to prevent deformation;

During the disassembly process, attention should be paid to protecting the surface quality of the ball bearing to ensure its performance;

During the operation, attention should be paid to removing surface dust to ensure the quality of the ball bearing.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

10 mm id ball bearing---FAQs Guide

2.Can 10 mm id ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

3.Are there self-aligning 10 mm id ball bearing that accommodate misalignment and shaft deflection in rotating equipment?

4.Are there 10 mm id ball bearing designed for use in critical medical equipment?

5.About 10 mm id ball bearing,What about the lead time?

6.How do different 10 mm id ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

7.How do sealed 10 mm id ball bearing prevent the ingress of contaminants and extend the bearing's service life?

8.Are there specific 10 mm id ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

9.How do 10 mm id ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

10.What are the considerations for choosing between open, shielded, or sealed 10 mm id ball bearing in specific applications?

11.Can 10 mm id ball bearing handle shock loads and high-impact conditions in heavy machinery?

12.Can 10 mm id ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

13.As a 10 mm id ball bearing manufacturer,What is your payment method?

14.What are the considerations for selecting sealed or shielded 10 mm id ball bearing to protect against contamination and retain lubrication?

15.Are there ceramic 10 mm id ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

16.What anti-corrosion coatings or treatments are available for 10 mm id ball bearing used in marine or outdoor applications?

1.Where can 10 mm id ball bearing be used?

10 mm id ball bearing are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

2.Can 10 mm id ball bearing operate in high-temperature environments like industrial ovens or furnaces, and how are they protected from heat-related damage?

10 mm id ball bearing are capable of working at temperatures up to +842°F (+450 °C). Special lubricants, seals and coatings make this possible by protecting the ball bearings from heat damage.

3.Are there self-aligning 10 mm id ball bearing that accommodate misalignment and shaft deflection in rotating equipment?

These 10 mm id ball bearing are particularly suitable for applications where misalignment can arise from errors in mounting or shaft deflection. A variety of designs are available with cylindrical and taper bores, with seals and adapter sleeves and extended inner rings.

4.Are there 10 mm id ball bearing designed for use in critical medical equipment?

Precision 10 mm id ball bearing are among critical components in medical devices that are vital to ensuring patient safety. Correct choice of suitable ball and ring materials and the right product design can ensure high-precision bearings — and medical devices — have a long service life.

Precision bearings are used in a wide variety of medical devices including surgical power tools, ventilators and heart pumps — and patient safety depends on them all. Whatever the device, there is an onus on medical device original equipment manufacturers (OEMs) to ensure that the right type of bearings are chosen, and fit precisely into the application.

5.About 10 mm id ball bearing,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

6.How do different 10 mm id ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove 10 mm id ball bearing: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

7.How do sealed 10 mm id ball bearing prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the 10 mm id ball bearing. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

8.Are there specific 10 mm id ball bearing designed for applications in the aerospace and aviation industries, and what standards do they adhere to?

Airframe control 10 mm id ball bearing are specialized bearings tailored for aircraft structures, particularly control systems and surfaces. Designed for low-speed oscillatory applications, they offer precision and support, effectively managing misalignments and flight-induced stresses.

Airframe Control bearings are lightweight, corrosion-resistant, grease-lubricated, and are sealed on most occasions. They come in precision grades for running accuracy.

9.How do 10 mm id ball bearing handle radial loads, axial loads, and combined loads, and what are their load-carrying capacities?

The type of bearing used also varies between these loads. While deep-groove 10 mm id ball bearing are better equipped to handle radial loads, thrust ball bearings are designed for axial loads. However, it's essential to note that most bearings, such as angular contact ball bearings, can handle both radial and axial loads.The Bearing Static Capacity, Co, is the maximum load that can safely be applied to a non-rotating bearing that will not cause subsequent bearing operation to be impaired. It is based on calculated contact stress at the center of the most heavily loaded rolling element where it contacts the Inner Race.

10.What are the considerations for choosing between open, shielded, or sealed 10 mm id ball bearing in specific applications?

While sealed bearings offer superior protection and maintenance advantages, shielded 10 mm id ball bearing can be more suitable in situations where minimal friction and operating temperature are crucial. It's essential to assess the operational environment and demands before making a selection.

11.Can 10 mm id ball bearing handle shock loads and high-impact conditions in heavy machinery?

As a general rule, 10 mm id ball bearing are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

12.Can 10 mm id ball bearing be used in vacuum or cleanroom environments, and what measures are taken to prevent outgassing or contamination?

Bearings specify stainless steel for vacuum or cleanroom applications as stainless steels used for the rings, balls and retainer exhibit low outgassing. They usually supply open or shielded stainless steel bearings as vacuum bearings as these will outgas less than a nitrile rubber sealed bearing.

13.As a 10 mm id ball bearing manufacturer,What is your payment method?

We accept T/T, PAYPAL or Western Union, credit card or via ALIBABA Assurance order.

14.What are the considerations for selecting sealed or shielded 10 mm id ball bearing to protect against contamination and retain lubrication?

First, the environment in which your 10 mm id ball bearing operate in can help you identify potential contaminants, allowing you to select your shields or seals accordingly. For example, shielded bearings have a gap that can allow finer contaminants or water from washdown applications to enter the bearing and get into the raceways.The challenge for sealing bearings is to seal the bearing by protecting the bearing from contaminants and running efficiencies.

15.Are there ceramic 10 mm id ball bearing designed for specific applications requiring high-temperature or corrosion resistance?

Ceramic 10 mm id ball bearing are a special type of bearing made of ceramic materials, offering superior wear resistance, corrosion resistance, and high-temperature performance. They provide excellent performance in applications requiring high speeds, high temperatures, and resistance to corrosion.

16.What anti-corrosion coatings or treatments are available for 10 mm id ball bearing used in marine or outdoor applications?

Corrosion Resistant Coatings.Whether 10 mm id ball bearing are manufactured from stainless steel or from chrome, anti-corrosion coatings can be applied. Compared to the natural state of the base metal, these coatings make surfaces less chemically reactive. In their selection of treatments or coatings, some industries choose to consult with the manufacturer of the bearings they use. This is because surface engineering is a highly specialized undertaking. These coatings used for their anti-corrosion properties to protect bearings in harsh environments include the following:Passivation (of stainless steel),Carbide and titanium nitride,Galvanized zinc,Nickel plating,Cadmium plating,TDC (thin dense chrome).