PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

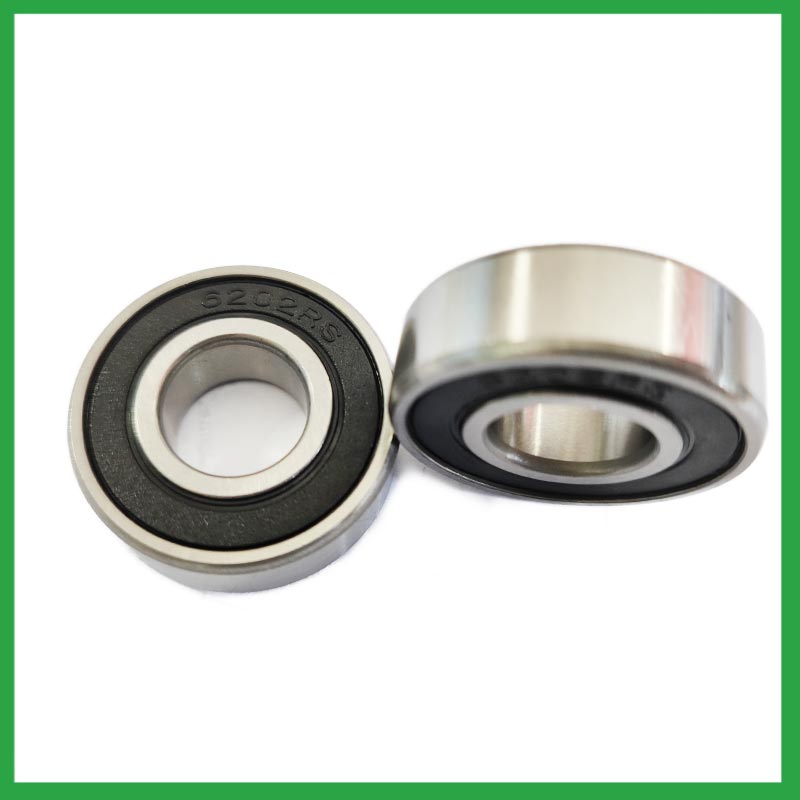

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Ningbo Haishu Nide International produces and supplies ball bearings.We have professional technical manpower for the mixing of polymer raw materials for the insulation coating of bearings, production of products, and quality control. We will grow together with customers with accurate quality, fast delivery and competitive prices.

In years of practice, we have established a strict quality assurance system. Our product range covers ball bearing,fan,thermal protector,insulation paper,motor cover and lamination,commutator,carbon brush, etc. They are widely used in fields such as fan motor,air condition motor,electric bicycle motor,washing machine motor,single and three phase induction motor,water pump motor,compress motor,electric automotive motor. We can produce OEM products and make the following drawings. Our principle is to prioritize service and quality!

| Parameter | Information |

| Product Name | 12 1 ball bearing reel |

| Place of Origin | Ningbo,China |

| Brand Name | Nide |

| Material | ceramics, etc. |

| Type | Ball |

| Warranty | 3months-1year |

| Port | Ningbo/Shanghai |

| Application | chemical equipment,various industrial equipment, etc. |

| Size(mm) | customize |

| Color | gray+customized |

| Precision Rating | as per customer's requirement |

| Certification | ISO 9001 Certification,CE-insulation paper inserting machine,CE-stator coil winding inserting machine,etc |

| Feature | Simple structure,High speed...etc |

| Packaging Details | Suitable for sea transportation |

| Service | one-stop service |

| Model Number | ball bearing |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

12 1 ball bearing reel can be used in household appliances, such as refrigerator door leaf wings,vegetable cutters,washing machines,mixers, etc; It can also be used in industrial fields, such as motors,reducers,bearing cabinets,dishwashers, etc.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

12 1 ball bearing reel---FAQs Guide

2.About 12 1 ball bearing reel,What about the lead time?

3.What are the advancements and innovations in 12 1 ball bearing reel technology that have emerged in recent years?

4.What are the after-sales services available for 12 1 ball bearing reel?

5.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

6.How do sealed 12 1 ball bearing reel prevent the ingress of contaminants and extend the bearing's service life?

7.What is the production capacity of the factory for 12 1 ball bearing reel?

8.As a 12 1 ball bearing reel manufacturer,can you supply samples?

9.What maintenance practices are recommended to extend the lifespan of 12 1 ball bearing reel and prevent premature failure?

10.Do 12 1 ball bearing reel come in various tolerance classes?

11.As a 12 1 ball bearing reel manufacturer,Your product certifications?

12.How do cage materials and designs impact 12 1 ball bearing reel performance and stability?

13.About 12 1 ball bearing reel,Will you check the products before shipment?

1.Can 12 1 ball bearing reel handle shock loads and high-impact conditions in heavy machinery?

As a general rule, 12 1 ball bearing reel are used at higher speeds and lighter loads than are roller bearings. Roller bearings perform better under shock and impact loading. Ball bearings tolerate misalignment better than roller bearings do. Roller bearings can handle heavy combined radial and thrust loads.

2.About 12 1 ball bearing reel,What about the lead time?

3-7 days for samples, 3-4 weeks for mass production.

3.What are the advancements and innovations in 12 1 ball bearing reel technology that have emerged in recent years?

Significant advancements have been made in 12 1 ball bearing reel steels over the years. Modern, ultra-clean bearing steels contain fewer and smaller non-metallic particles, giving ball bearings greater resistance to contact fatigue.

4.What are the after-sales services available for 12 1 ball bearing reel?

If you find problems or failures in the assembly or use of the bearings , which needs to consult and other services, please feedback to Nide International in time.

5.How do manufacturers address concerns related to bearing noise and vibration in sensitive equipment?

From a 12 1 ball bearing reel manufacturing perspective, a low noise or vibration rating is achieved by paying attention to the surface finish of the raceways and balls, their roundness, and selecting the correct cage design. Finely filtered low noise greases can also be used to reduce vibrations.

6.How do sealed 12 1 ball bearing reel prevent the ingress of contaminants and extend the bearing's service life?

Contact seals are a type of seal where the sealing lip physically touches the inner raceway of the 12 1 ball bearing reel. They create a narrow line or zone of contact that forms a barrier to prevent the escape of lubricants and the ingress of contaminants. Because the seal keeps dirt and other contaminants out, it can offer a longer operating life of the bearing or prevent premature bearing failure. Sealed bearings can be considered lubricated for life, which eliminates the need for a relubrication process.

7.What is the production capacity of the factory for 12 1 ball bearing reel?

The production capacity of Ningbo Haishu Nide International is:50000000pcs/month

8.As a 12 1 ball bearing reel manufacturer,can you supply samples?

Sure, samples can be provided free of charge, and the buyer pay the postage of the sample.

9.What maintenance practices are recommended to extend the lifespan of 12 1 ball bearing reel and prevent premature failure?

Proper handling and installation of 12 1 ball bearing reel is essential to preventing premature failure. Ensure that bearings are stored and transported in a clean, dry, and vibration-free environment. During installation, ensure that bearings are properly aligned, and torque is applied correctly.

10.Do 12 1 ball bearing reel come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

11.As a 12 1 ball bearing reel manufacturer,Your product certifications?

ISO9001:2015 certificate,ISO 9001 Certification,CE-stator,etc.

12.How do cage materials and designs impact 12 1 ball bearing reel performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision 12 1 ball bearing reel directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing.

Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

13.About 12 1 ball bearing reel,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.