PRODUCTS

CONTACT US

Ningbo Nide International Co., Ltd.

一一

· Contact person:Jack Zeng

· Mob/Whatspp/WeChat:0086-13738869026

· Email:emarketing@nide-group.com;marketing4@nide-group.com

· Add:No. 169, Wohushan Road, Daqi Subdistrict, Beilun District, Ningbo, China

Nide team could manufacture ball bearing as per customer’s drawing and samples.

If customer only has samples, we could also design drawing fo r our customer.

We also provide customized service.

Our ball bearing is widely applied the different industrials.

Haishu Nide International is a professional ball bearing manufacturer in China, exporting various high-precision bearings to target industries around the world since 2010. The factory is located in Suzhou, with a factory area of 9000 square meters and 102 employees. It mainly produces single machine and fully automatic production lines for external rotor production machines,rotor assembly line,motor stator and other customized machine tools or production lines.

We has professional technology and rich experience in quality control, customs clearance, commodity inspection, cargo transposition, insurance.We has rich stocks and is able to provide long tern stable supply, including rapid and urgent cargo handing . With companies in Europe, America , Japan and Korea, we are an integrated supplier of bearing, marketing all over the world.

| Parameter | Information |

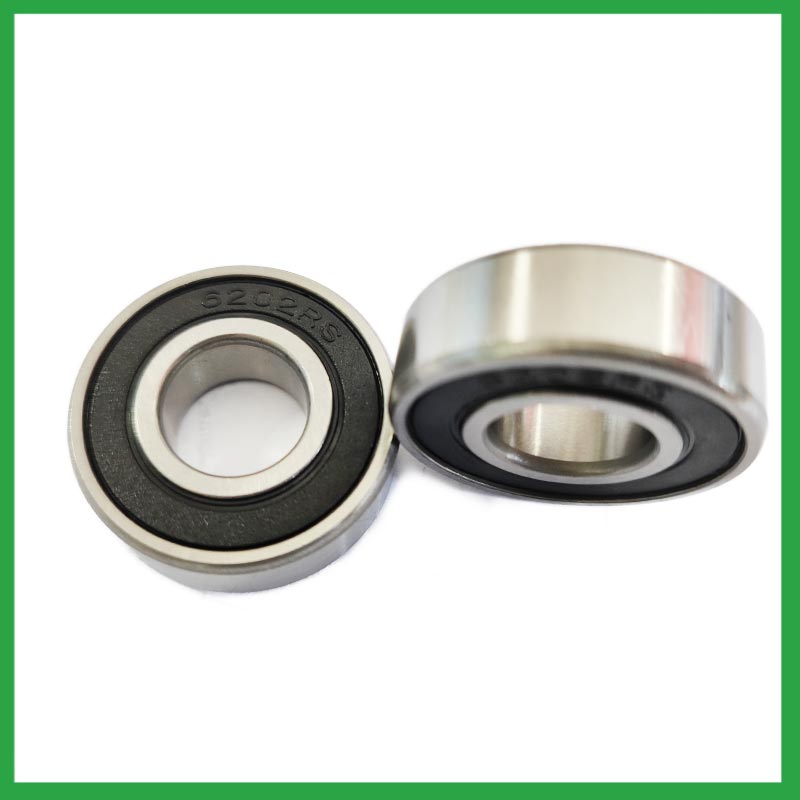

| Product Name | 6002 2rs ball bearing |

| Brand Name | Nide |

| Place of Origin | China |

| Type | Ball |

| Material | stainless steel, etc. |

| Sample | Avaible |

| Warranty | 3months-1year |

| Lubrication | Dry/ Oil |

| Application | high-speed electric tools,automotive engines, etc. |

| Port | Ningbo/Shanghai |

| Size(mm) | customize |

| Export Country | Argentina,Brazil,South Korea,Europa Island,Uganda,Dominican Republic,Turkey,Guatemala...etc |

| Export region | Asia,Europe,Oceania... |

| Certification | ISO 9001 Certification,CE-insulation paper inserting machine,ISO9001:2015 certificate,etc |

| Precision Rating | as per customer's requirement |

| Feature | Good wear resistance,Simple structure...etc |

| Packaging Details | Suitable for sea transportation |

| Color | gray+customized |

| Seals Type | Rubber seals |

| Service | Prompt Delivery |

| Supply Ability | 100000-500000 Piece/Pieces per Month |

| Lead time (days) | 15-20 (To be negotiated) |

Please note: The above table data is for reference only. For specific information, please contact us.

The precision range of 6002 2rs ball bearing is from ABEC7 to ABEC9, with a particle size of 0.3 μ m. Among them, ABEC9's ball bearings have the best precision range and are widely used in the electronics industry, precision measurement industry, and so on.

During the installation process, pollution from dirt and wear media should be prevented;

Temperature and humidity should be controlled to avoid excessive temperatures during startup and operation;

It should be operated and lubricated in the correct reverse direction to avoid unnecessary damage.

Ball bearings have many advantages, making them highly competitive in the market.

Firstly, they are very durable and have good wear performance, making their service life longer than many other types of bearings.

Secondly, they are easy to install and can provide low friction performance in various applications.

Thirdly, they require a relatively low level of maintenance, making them cost-effective.

In addition, compared to many other types of bearings, their purchase cost is relatively low, making them an economical choice.

6002 2rs ball bearing---FAQs Guide

2.Can 6002 2rs ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

3.What are the 6002 2rs ball bearing product skill training options?

4.What is the significance of 6002 2rs ball bearing lubrication, and how does it affect bearing lifespan and performance?

5.Are there ongoing research and development efforts aimed at improving 6002 2rs ball bearing materials, designs, and lubrication techniques?

6.About 6002 2rs ball bearing,Will you check the products before shipment?

7.What is the load distribution within a 6002 2rs ball bearing, and how does it vary between different bearing configurations?

8.How do cage materials and designs impact 6002 2rs ball bearing performance and stability?

9.What are the standard sizes and dimensions of 6002 2rs ball bearing?

10.Where can 6002 2rs ball bearing be used?

11.Do 6002 2rs ball bearing come in various tolerance classes?

12.What is the role of 6002 2rs ball bearing in reducing friction and energy loss in rotating machinery?

13.About 6002 2rs ball bearing,Can I add my own logo?

14.How do different 6002 2rs ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

15.Can 6002 2rs ball bearing be used in both vertical and horizontal orientations?

1.Are there miniature 6002 2rs ball bearing designed for use in precision instruments and small-scale mechanisms?

Miniature bearings, despite their small size, play a significant role in various industries and applications. These compact powerhouses, typically measuring less than one inch in outer diameter, offer exceptional precision, durability, and reliability. Miniature bearings find extensive use in precision instruments and robotics.

2.Can 6002 2rs ball bearing be customized with special coatings or treatments to meet specific industry standards or regulatory requirements?

Yes, 6002 2rs ball bearing can be customized with special coatings or treatments to meet specific industry standards or regulatory requirements.

1. Corrosion-resistant coatings: These coatings are used to protect the bearings from corrosion caused by exposure to moisture, chemicals, and other corrosive substances.

2. High-temperature coatings: These coatings are used to improve the thermal stability and performance of bearings in high-temperature environments.

3. Food-grade coatings: These coatings are specially designed for applications in the food and beverage industry, where bearings come into contact with food, beverage, or pharmaceutical products.

4. Anti-static and non-conductive coatings: These coatings are used to dissipate static electricity, which can cause damage to electronic components.

5. Specialized lubrication treatments: Bearings can be treated with specialized lubricants that meet specific industry standards or regulatory requirements.

3.What are the 6002 2rs ball bearing product skill training options?

Quality comes from being controlled rather than be done. On the basis of the escalating production equipment and optimized process, Nide spare no efforts and keeps improving for quality control. Quality assurance covered with system, technology and human resources are in full swing.

4.What is the significance of 6002 2rs ball bearing lubrication, and how does it affect bearing lifespan and performance?

Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction.

5.Are there ongoing research and development efforts aimed at improving 6002 2rs ball bearing materials, designs, and lubrication techniques?

A custom 6002 2rs ball bearing can satisfy almost any customer’s needs. Your application may need a needle roller or ball bearing, a radial or angular contact design, a plain carbon steel bearing with anti-corrosion coatings or stainless steel, a thrust bearing or a spherical bearing, tight or loose radial play, sealed or non-sealed designs

6.About 6002 2rs ball bearing,Will you check the products before shipment?

Yes, We have a professional QC team. Products will be strictly inspection before shipment.

7.What is the load distribution within a 6002 2rs ball bearing, and how does it vary between different bearing configurations?

The load distribution between the rolling elements and raceway is crucial in performance evaluation of rolling element bearings. Determine the load distribution by measuring the strain response at the bearing surface with a notched housing. Finite element analysis shows that the introduction of notches does not affect the load distribution. An experimental system was developed to investigate the load distribution in a cylindrical roller bearing. The experimental static load distribution agrees well with the theoretical calculation. The dynamic load at specific position of load zone reflects the manufacture difference among rollers and dynamic balance of distributing loads.

8.How do cage materials and designs impact 6002 2rs ball bearing performance and stability?

As the core component of rotating machinery, the performance and reliability of high-precision 6002 2rs ball bearing directly affect the overall performance and life of the machine and instrument . The increase of the rotational speed will aggravate the collision and friction of the cage, which will lead to the decrease of the rotational stability of the cage. The unstable movement of the cage could in turn lead to more severe collision and wear, thus reducing the life and reliability or even the destruction of the bearing.

Therefore, it is very necessary to study the cage stability to guarantee the stable operation of bearings. However, the dynamic characteristics of the cage is very complex. Parameters such as load, rotational speed and lubrication may affect its kinematic and tribological conditions, which leads to the change of its motion behavior.

9.What are the standard sizes and dimensions of 6002 2rs ball bearing?

6002 2rs ball bearing size charts are widely available, and can be used to find the measurements of a specific bearing. Series 6200 and 6300 are the most commonly used, and typically range from 10 x 30 x 9 mm (. 394 x 1.181 x . 354 in) to 150 x 320 x 65 mm (5.906 x 12.598 x 2.559 in).

10.Where can 6002 2rs ball bearing be used?

6002 2rs ball bearing are very versatile. They can be designed to withstand radial loads, axial loads and combined radial/axial loads at various operating speeds. These characteristics, combined with the relative cost and compactness of the design, give it universal appeal within the industry. Ball bearings are widely used in electric motors, gear reducers and pumps. Serving the automotive, home appliances, aerospace, oil and gas drilling, and mining sectors.

11.Do 6002 2rs ball bearing come in various tolerance classes?

Bearing tolerances are standardized by classifying bearings into the following six classes (accuracy in tolerances becomes higher in the order described): 0, 6X, 6, 5, 4 and 2.

12.What is the role of 6002 2rs ball bearing in reducing friction and energy loss in rotating machinery?

6002 2rs ball bearing reduce friction by using smooth balls lubricated with oil or grease that freely roll between a smooth inner and outer surface. The main concept of the ball bearing is that objects that roll past each other produce less friction than if the objects were sliding against each other.

13.About 6002 2rs ball bearing,Can I add my own logo?

Yes, you can add your logo on bearings and packing box. We supply OEM SERVICE including bearing's size, logo, packing, etc.

14.How do different 6002 2rs ball bearing designs, such as deep groove, angular contact, or thrust bearings, cater to specific applications?

Deep groove 6002 2rs ball bearing: Deep groove ball bearings are the most common type. They can handle both radial and axial loads. Angular contact ball bearings: Angular contact ball bearings have higher than average internal axial clearance. They can handle axial loads in one direction and moderate radial loads.

15.Can 6002 2rs ball bearing be used in both vertical and horizontal orientations?

Sleeve Bearings: Sleeve bearings, also known as plain bearings, employ a simple yet effective mechanism. A cylindrical sleeve separates the rotating shaft from the stationary portion of the bearing, reducing friction and enabling smooth rotation. Sleeve bearings are characterized by their quiet operation, cost-effectiveness, and suitability for horizontal mounting orientations.

Ball Bearings: Ball bearings introduce small metal balls between the moving parts, providing enhanced durability and reduced friction. This design allows for smoother and more efficient rotation, making ball bearings well-suited for high-performance applications and vertical installations.